Processing device and processing method of double-layer foam pipe and products thereof

A processing device and foam tube technology, which is applied to tubular objects, other household utensils, household utensils, etc., can solve the problems of short service life, easy weathering damage, single appearance, etc., and achieve improved heating area and effect, and firm adhesion , beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

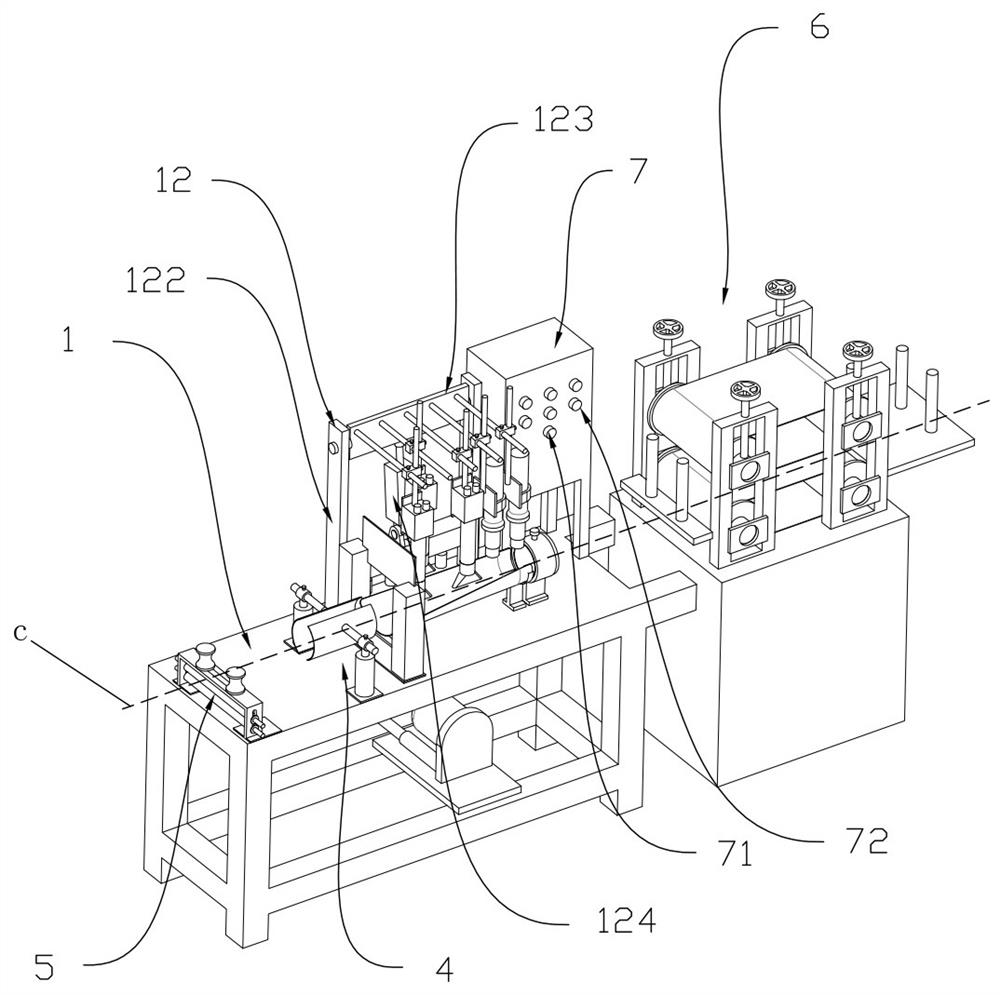

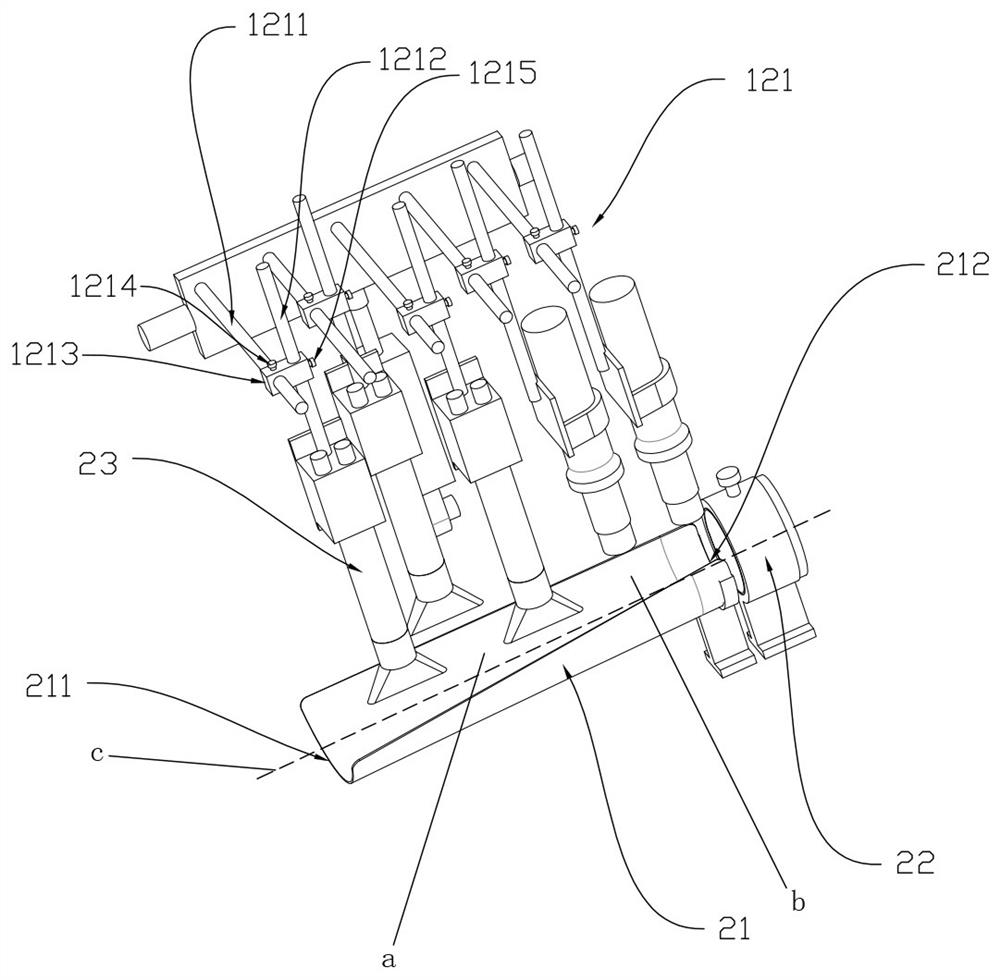

[0017] The specific embodiment of the processing device of the double-layer foam pipe of the present invention is as follows: Figure 2-7 As shown, the console 1 and the guide plate 21 and the hot air pipe 23 arranged on the console 1 are included. The guide plate 21 has an inlet end 211 and an outlet end 212. The curvature from the inlet end 211 to the outlet end 212 gradually increases, and the hot air The pipe 23 has an air outlet (not marked in the figure), and the guide plate 21 includes another kind of foaming material thermal bonding station a and self foaming material thermal bonding station b, and the air outlet faces other kind of foaming material thermal bonding At station a, the air outlet is directed towards self-foaming material thermal bonding station b.

[0018] Other foaming material thermal bonding station a and self-foaming material thermal bonding station b are specific thermal bonding stations that exist in the guide plate 21, and other foaming material th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com