Method for improving cable stripping efficiency of cable for engineering

A cable and efficiency technology, applied in the field of improving the stripping efficiency of engineering cables, can solve the problems of troublesome operation, unsuitable cable stripping operation, low efficiency, etc., to reduce maintenance costs, improve stripping efficiency, and expand the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051] Example 1

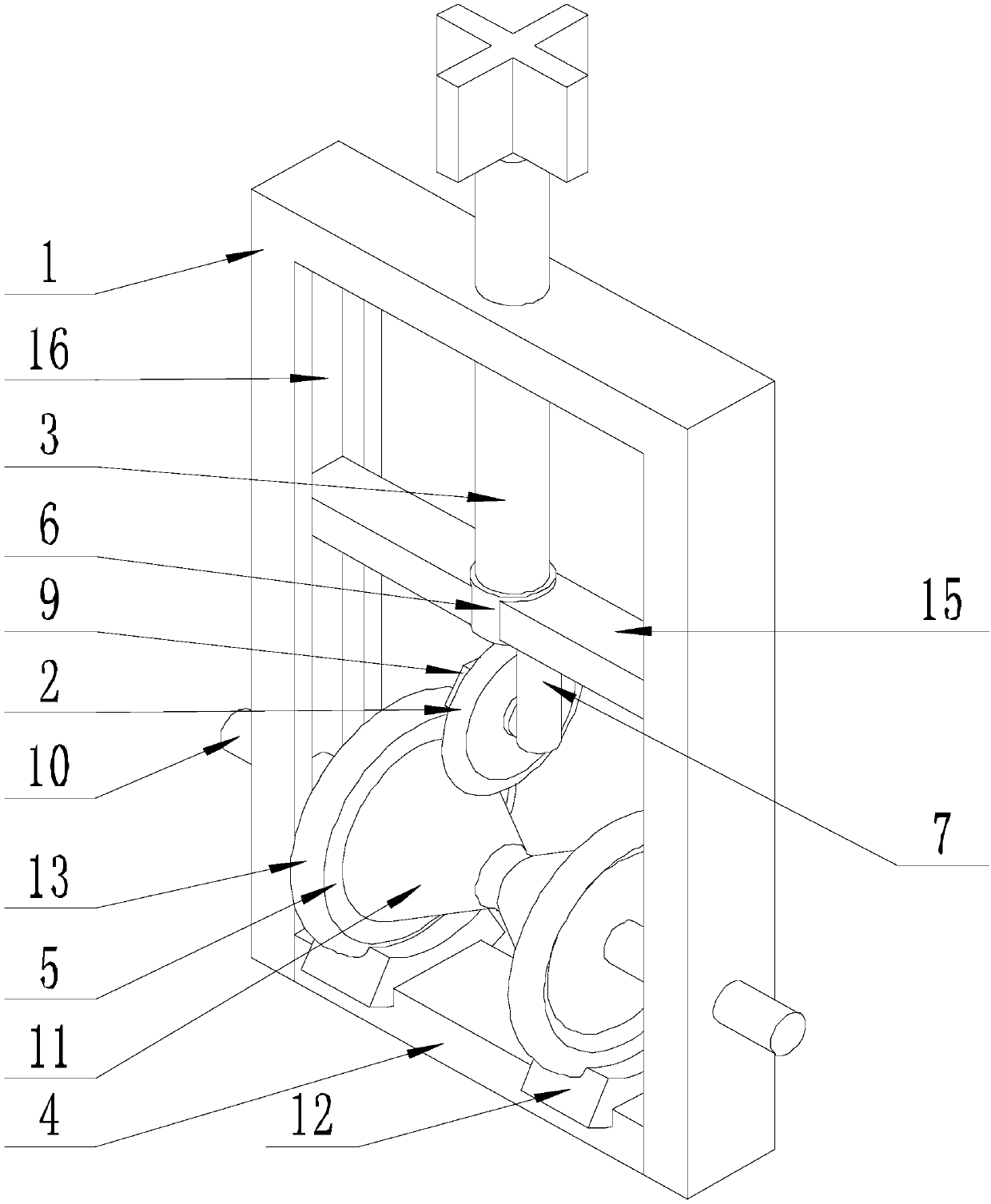

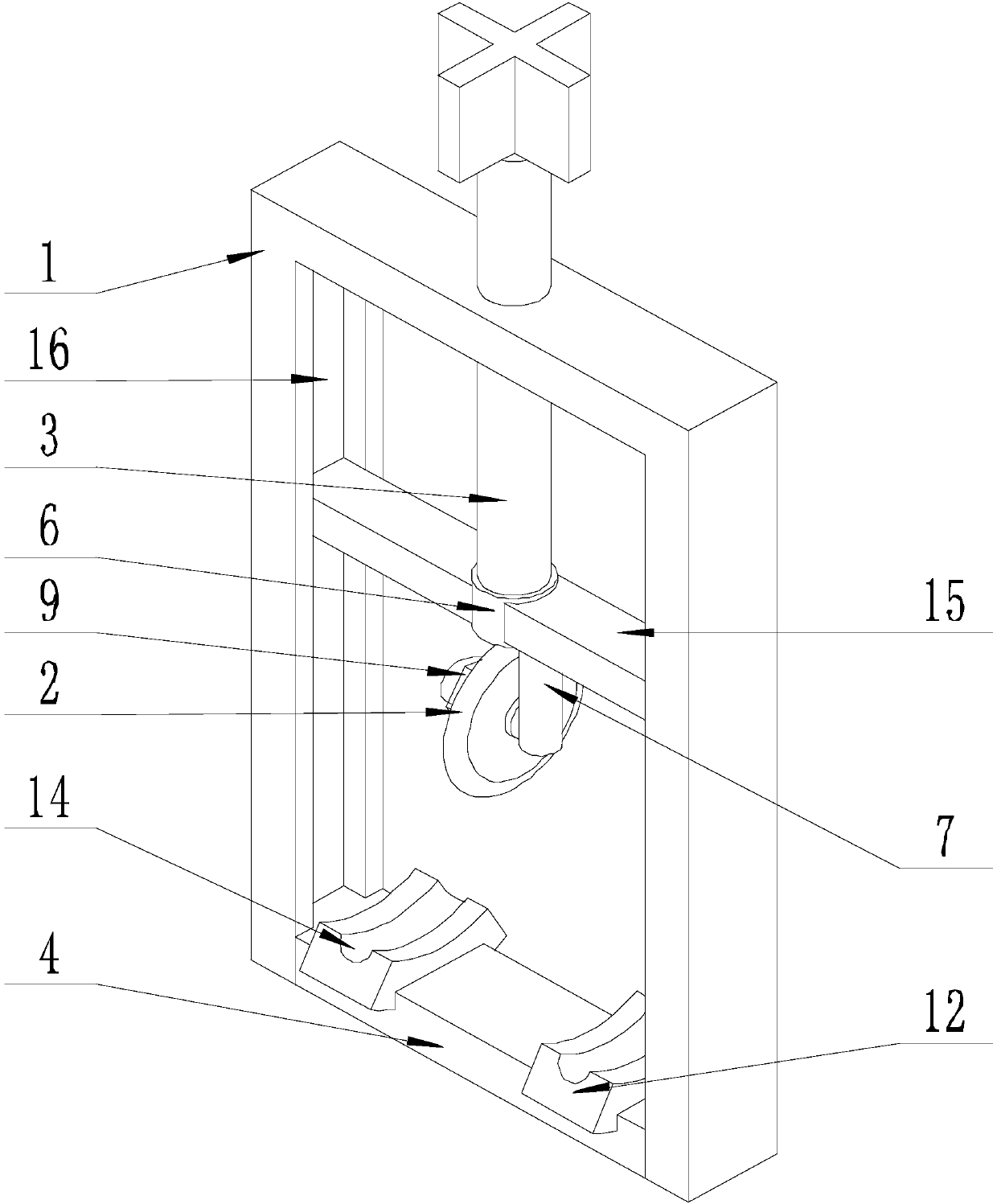

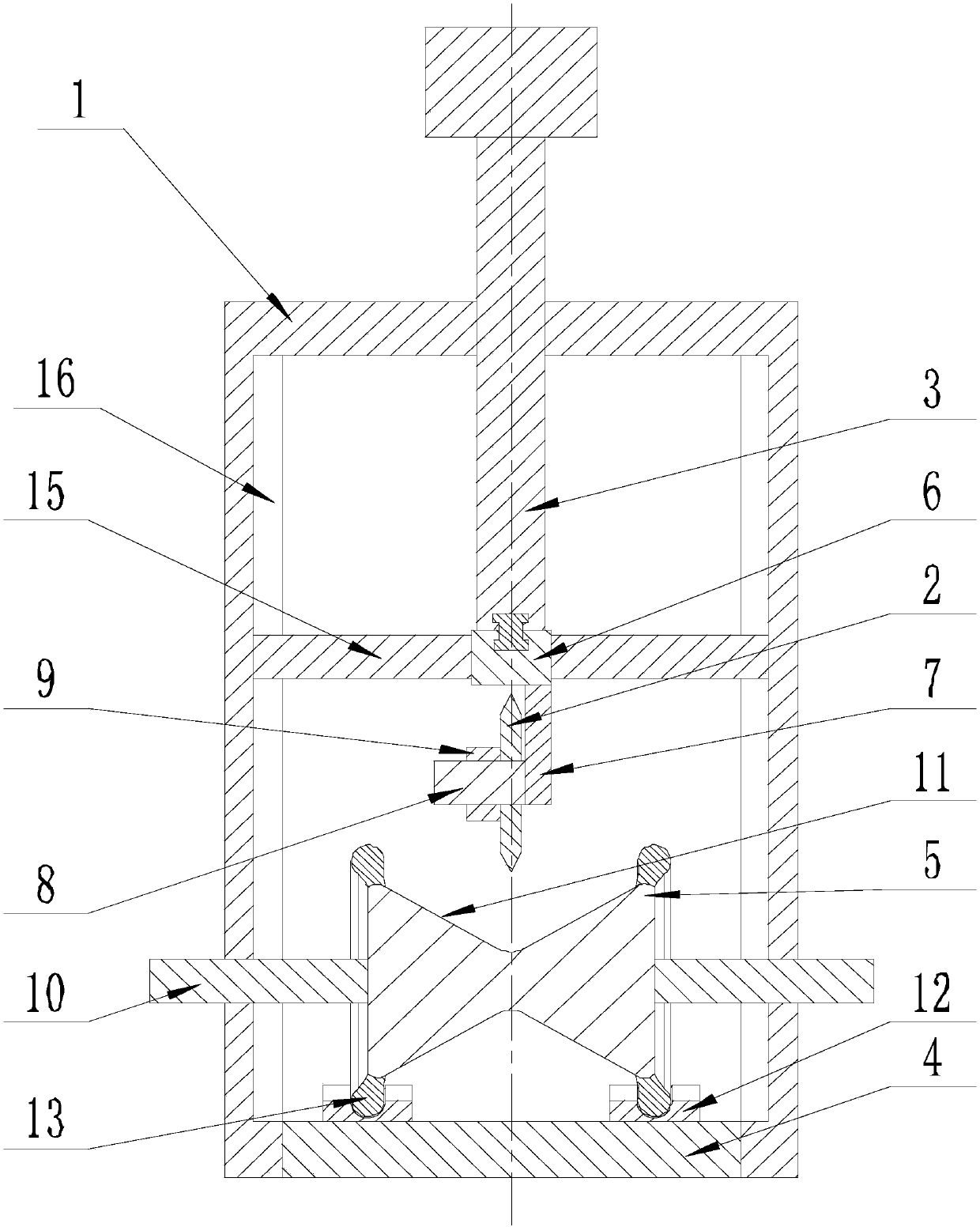

[0052] Such as Figure 1-Figure 4 As shown, the method for improving the stripping efficiency of engineering cables according to the present invention includes the following steps:

[0053] Step A: First, screw the screw 3 to the top of the portal frame 1, and one end of the screw 3 penetrates the portal frame 1, and the other end of the screw 3 is rotatably connected to the rotating block 6, the end of the rotating block 6 away from the screw 3 Connect with the fixed arm 7 in the fixed assembly;

[0054] Step B: Set the cutter 2 on the connecting shaft 8, then connect the nut 9 to the connecting shaft 8, and tighten the nut 9;

[0055] Step C: Connect the two ends of the rotating shaft 5 to a supporting shaft 10 respectively, and then connect the supporting shafts 10 to a frame edge parallel to the center line of the portal frame 1 respectively;

[0056] Step D: Put the cable in the annular groove 11 of the rotating shaft 5, and make the axis of the cable perpendic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap