Kitchen garbage processing method and application

A technology of food waste and treatment methods, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as improper disposal methods, affecting food safety and ecological safety, and achieve simple and easy-to-operate treatment process Strong, reduce environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

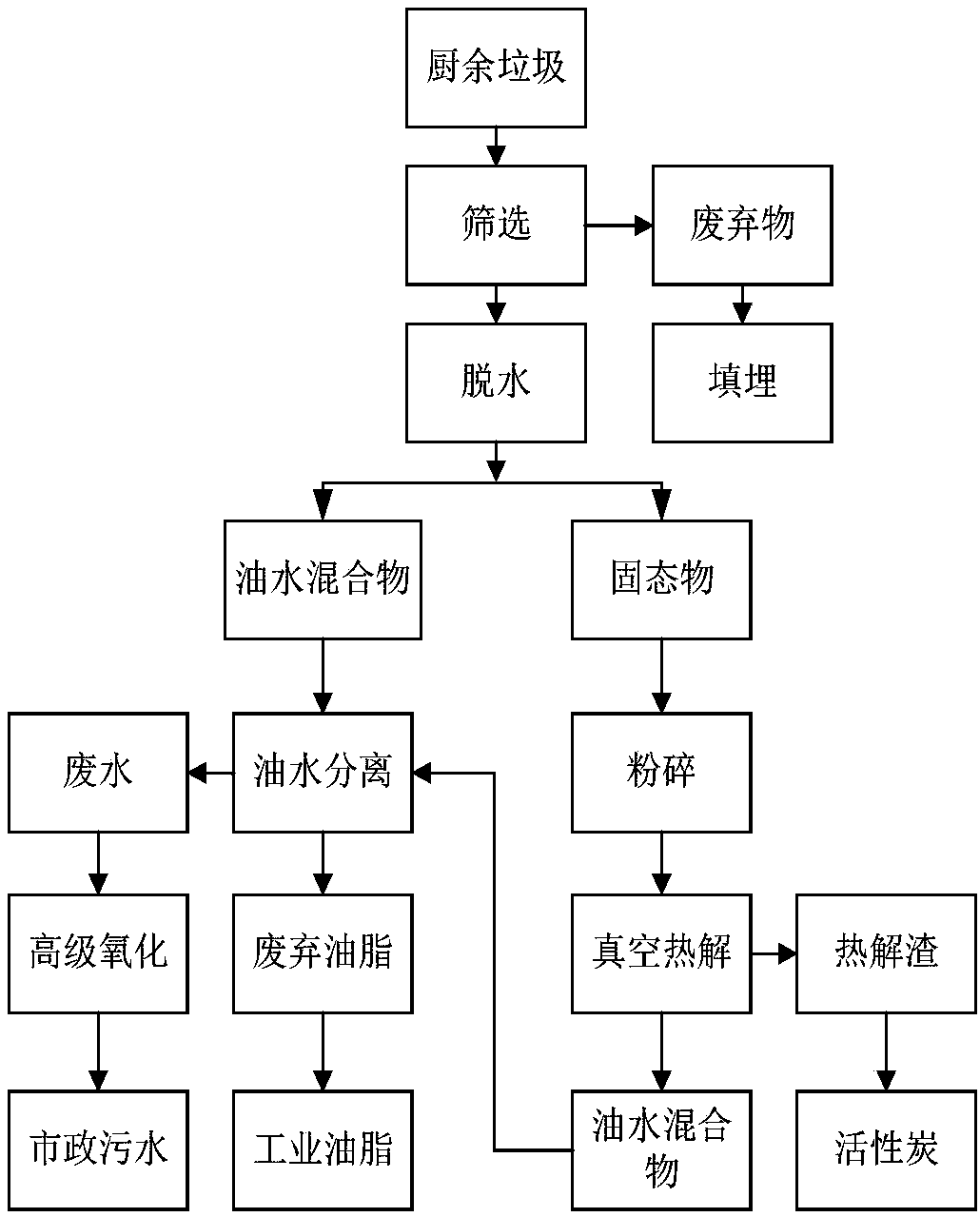

[0030] This embodiment provides a treatment method for kitchen waste, which mainly includes:

[0031] Screen the kitchen waste to remove waste such as broken tableware, glass, used cans and stones.

[0032] A filter press is used to filter and dehydrate the screened kitchen waste to obtain the first oil-water mixture and filter residue.

[0033] Under the condition of vacuum degree of -0.01MPa and pyrolysis temperature of 350°C, vacuum pyrolysis is carried out on the press filter residue for a pyrolysis time of 30 minutes to obtain the second oil-water mixture and pyrolysis residue. A granulator is used to granulate the pyrolysis slag, and the particle diameter of the obtained activated carbon particles is 0.2 cm.

[0034] The oil-water separation of the first oil-water mixture and the second oil-water mixture is carried out by adopting gravity separation and centrifugal separation to obtain grease and waste water. A spiral vertical ozone reactor was used to oxidize the wast...

Embodiment 2

[0036] This embodiment provides a treatment method for kitchen waste, which mainly includes:

[0037] Screen the kitchen waste to remove waste such as broken tableware, glass, used cans and stones.

[0038] A filter press is used to filter and dehydrate the screened kitchen waste to obtain the first oil-water mixture and filter residue.

[0039] Under the condition of vacuum degree of -0.1MPa and pyrolysis temperature of 700°C, vacuum pyrolysis was carried out on the press filter residue for 90 minutes to obtain the second oil-water mixture and pyrolysis residue. A granulator is used to granulate the pyrolysis slag, and the particle diameter of the obtained activated carbon particles is 0.5 cm.

[0040] The oil-water separation of the first oil-water mixture and the second oil-water mixture is carried out by adopting gravity separation and centrifugal separation to obtain grease and waste water. A spiral vertical ozone reactor was used to oxidize the wastewater under the con...

Embodiment 3

[0042] This embodiment provides a treatment method for kitchen waste, which mainly includes:

[0043] Screen the kitchen waste to remove waste such as broken tableware, glass, used cans and stones.

[0044] A filter press is used to filter and dehydrate the screened kitchen waste to obtain the first oil-water mixture and filter residue.

[0045]Under the conditions of vacuum degree of -0.05MPa and pyrolysis temperature of 550°C, vacuum pyrolysis was carried out on the press filter residue for a pyrolysis time of 40 minutes to obtain the second oil-water mixture and pyrolysis residue. A granulator is used to granulate the pyrolysis slag, and the particle diameter of the obtained activated carbon particles is 0.3 cm.

[0046] The oil-water separation of the first oil-water mixture and the second oil-water mixture is carried out by adopting gravity separation and centrifugal separation to obtain grease and waste water. A spiral vertical ozone reactor was used to oxidize the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com