Rare earth scintillator material with light guide structure, and preparation method and application thereof

A technology of scintillator materials and light guide structures, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve the problems of low X-ray conversion efficiency and reduced imaging resolution of image screens, and improve imaging resolution High efficiency, easy operation, and reduced scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

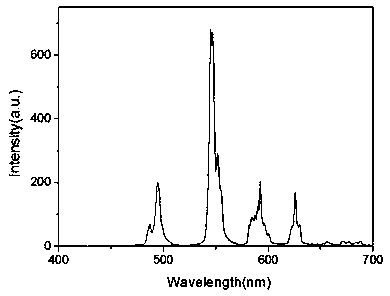

[0029] Example 1 Y 0.997 Tb 0.003 AlO 3 / Al 2 o 3 Rare Earth Eutectic Scintillator Materials

[0030] A rare earth scintillator material with a light guiding structure, the chemical expression of the scintillator material is Y 0.997 Tb 0.003 AlO 3 / Al 2 o 3 , the preparation method of the scintillator material is as follows:

[0031] (1) Weigh the raw material yttrium oxide (Y 2 o 3 ) 2.5890g, terbium oxide (Tb 4 o 7 ) 0.0129g, alumina (Al 2 o 3 ) 3.9255g, add absolute ethanol as a dispersant to the raw material, put it into an alumina crucible after fully grinding in an agate mortar, put the crucible into a box-type muffle furnace, and heat up at 1400°C with a heating rate of 4°C / min. Sinter in a CO reducing atmosphere for 10 h, after the sample is cooled to room temperature, grind to powder to obtain the eutectic powder pre-sintered raw material;

[0032] (2) Put the pre-fired raw materials into an iridium crucible with a small hole at the bottom, place the iri...

Embodiment 2

[0034] Example 2 Y 0.95 Tb 0.05 AlO 3 / Al 2 o 3 Rare Earth Eutectic Scintillator Materials

[0035] Weigh raw material yttrium oxide (Y 2 o 3 ) 2.4670g, terbium oxide (Tb 4 o 7 ) 0.2150g, alumina (Al 2 o 3 ) 3.9255g, by the same method as in Example 1, obtain Y with a pull-down rate of 1.5 mm / min 0.95 Tb 0.05 AlO 3 / Al 2 o 3 Rare earth eutectic scintillator materials.

Embodiment 3

[0036] Example 3 Gd 0.99 Tb 0.01 AlO 3 / Al 2 o 3 Rare Earth Eutectic Scintillator Materials

[0037] Weigh the raw material gadolinium oxide (Gd 2 o 3 ) 4.1270g, terbium oxide (Tb 4 o 7 ) 0.0430g, alumina (Al 2 o 3 ) 3.9255g, by the same method as in Example 1, obtain Gd with a pull-down rate of 2.0 mm / min 0.99 Tb 0.01 AlO 3 / Al 2 o 3 Rare earth eutectic scintillator materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com