Polishing and burnishing device for pipeline

A technology of polishing and grinding, which is applied in the direction of grinding driving device, grinding/polishing equipment, grinding machine, etc., can solve the problems of inapplicability, and achieve the effects of simple structure, improved scope of application, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

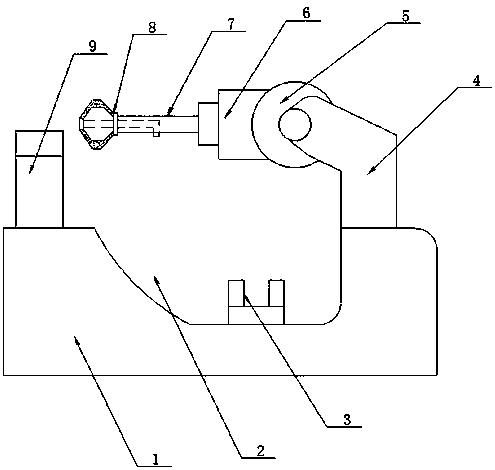

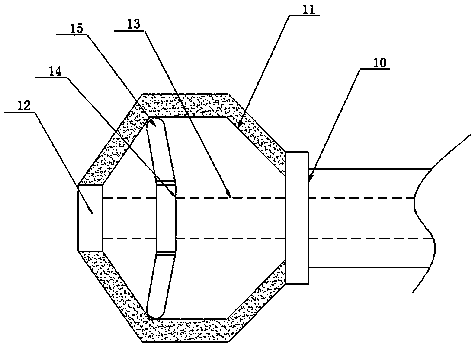

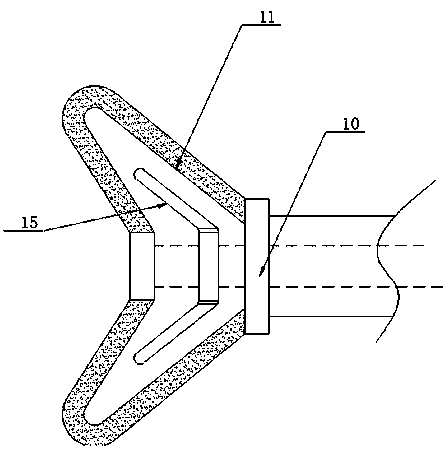

[0020] see as Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical scheme: it includes a grinding base 1, an operating groove 2, a profile fixing seat 3, a support bracket 4, a rotating base 5, a driving motor 6, a telescopic transmission connecting rod 7, and a grinding head 8 , pipe fixing frame 9; the center of described grinding base 1 is provided with operating groove 2, and the inside of operating groove 2 is fixed with section bar fixing seat 3; The right side upper end of described grinding base 1 is fixed with support bracket 4, The top of the support bracket 4 is fixed with a rotating base 5, the left side of the rotating base 5 is connected with a drive motor 6, the left side of the drive motor 6 is connected with a telescopic transmission link 7, and the top of the telescopic transmission link 7 is fixed with a grinding head 8; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap