New Biomass Hot Oxygen Burner

A technology of biomass and hot oxygen, which is applied in the direction of combustion equipment, lighting and heating equipment, and solid fuel combustion. Feed continuity, reduce heat loss, and improve fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

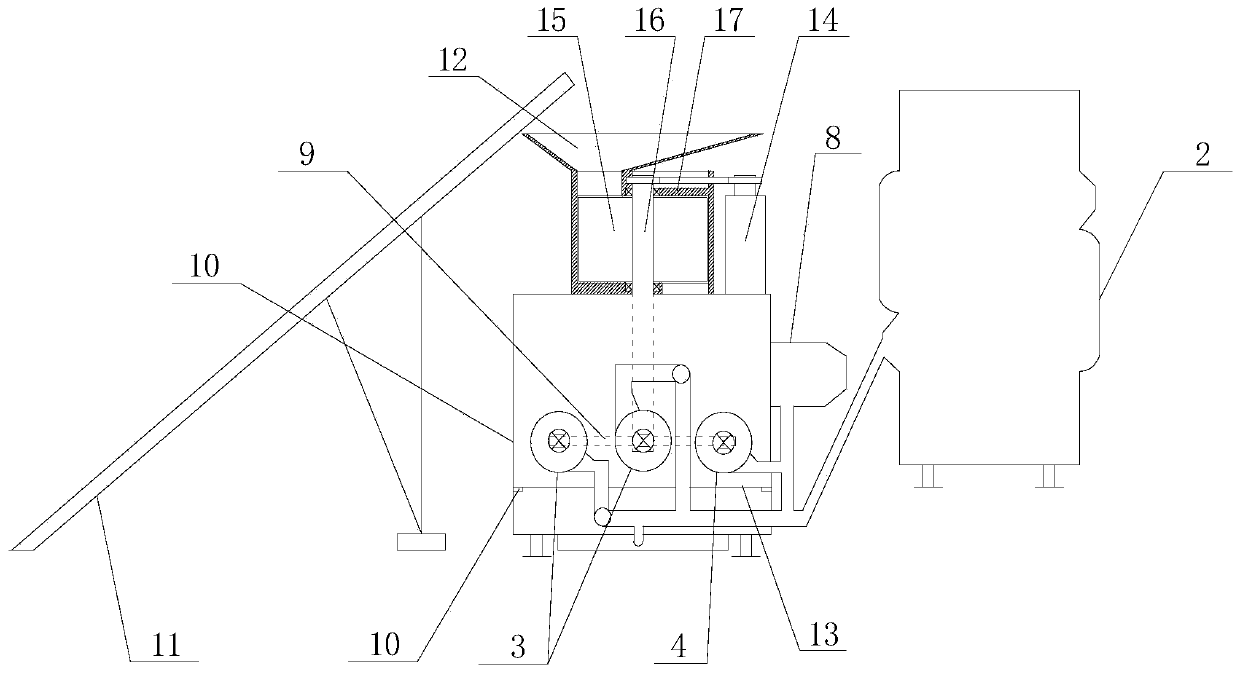

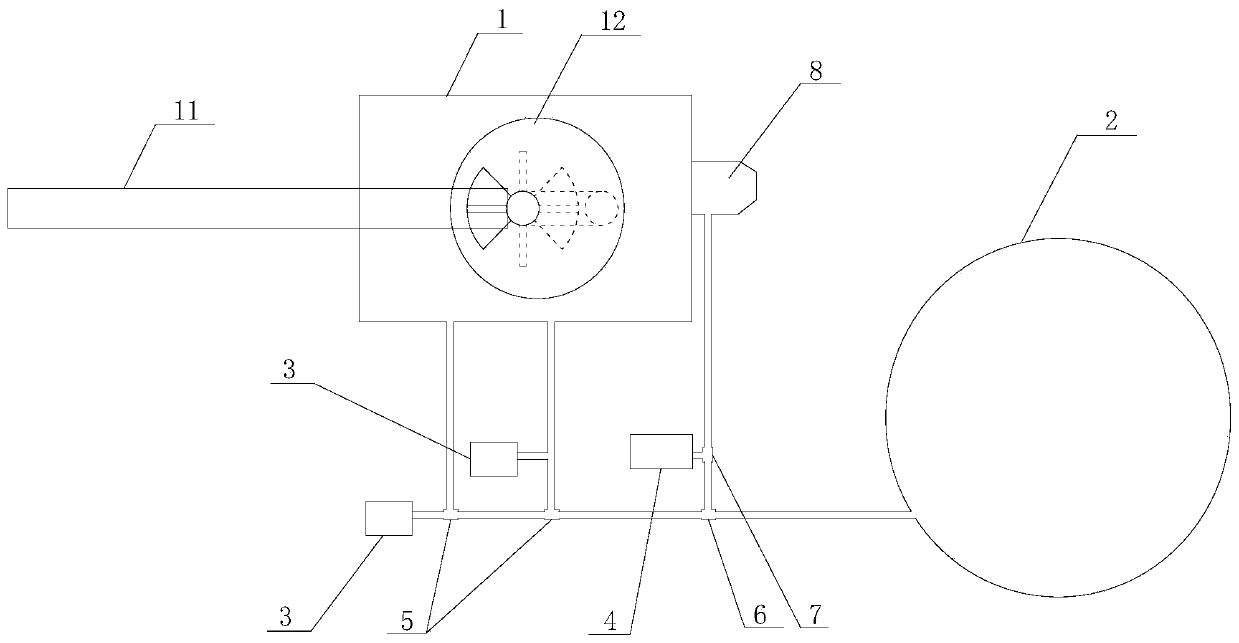

[0028] Such as figure 1 , 2 , 3 shown: the novel biomass hot oxygen gas burner of the present embodiment comprises a feeding mechanism 11, a cracking chamber 1, waste heat recovery equipment 2, a first induced draft fan 3, a second induced draft fan 4, a three-way valve A5, three Through valve B6, three-way valve C7 and some air pipes;

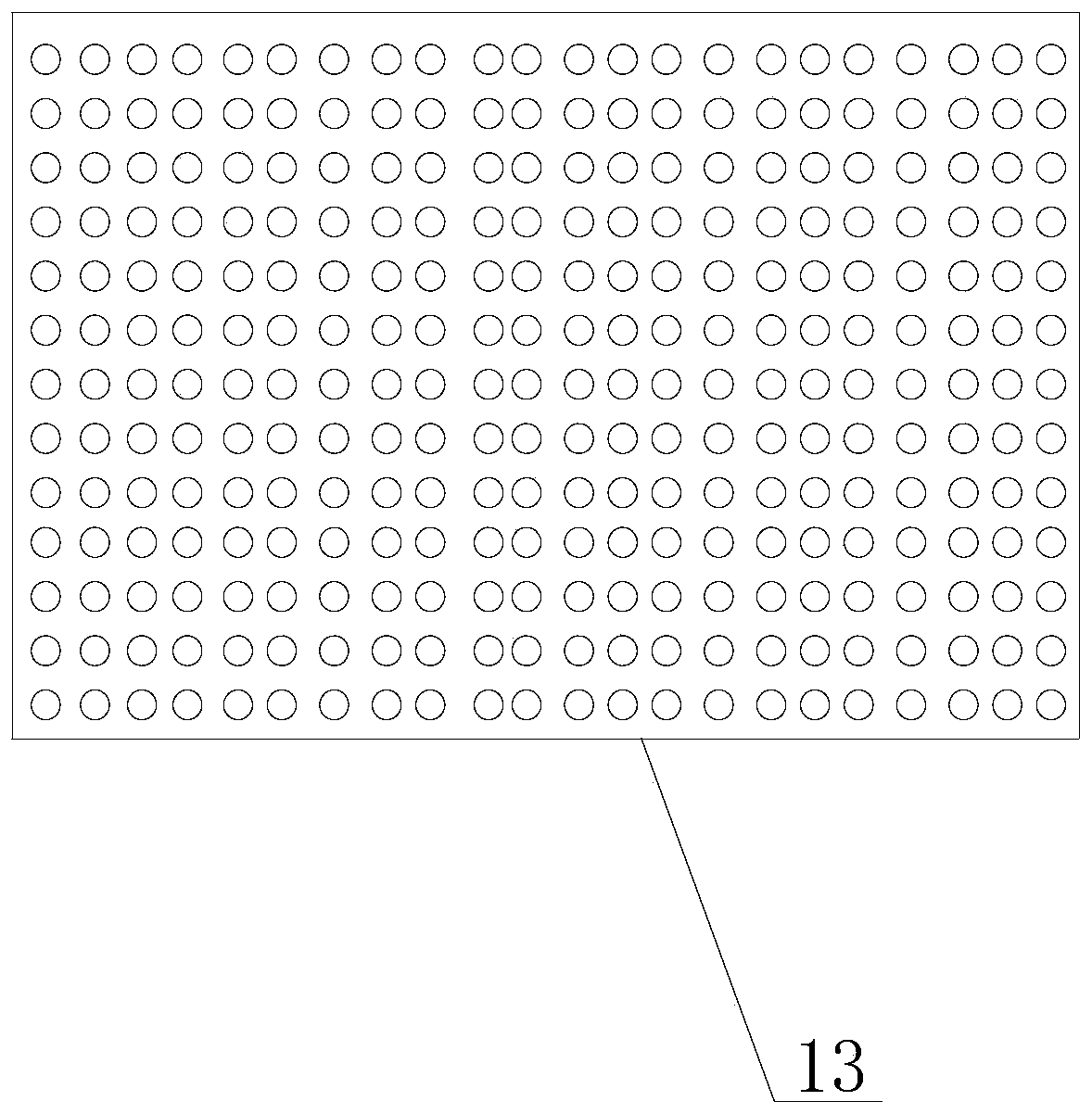

[0029] The top of the cracking chamber 1 is provided with a filler port; the filler port is provided with two partitions 17 up and down and a filler pusher 15 installed between the two partitions 17; the filler pusher 15 includes a vertical The wheel shaft 16 and four push plates fixed on the outer circumference of the wheel shaft 16; the wheel shaft 16 is rotatably connected to two partitions 17; each of the two partitions 17 is provided with a feeding port and the two feeding ports are at an angle of 180° Arrangement, the feed inlet is a fan-shaped structure with a central angle of less than 90°; the cracking chamber 1 is also equipped wit...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the radius of the feed inlet on the upper and lower partitions 17 is doubled, and the diameter of the feed inlet is increased so that it can adapt to irregular fuels and solve the problem of single fuel. , due to the adoption of the vertical packing push wheel 15 structure, the fuel falls on the lower partition 17 after entering the upper feed port, rather than within the angle between the push plates of the packing push wheel 15, so the fuel can be avoided stuck phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com