Oil-proof heat-proof automobile engine hollow pipe and preparation method thereof

An automobile engine and heat-resistant technology, which is applied in the field of automobile engine hollow pipes, can solve the problems of automobile engine failure, high work intensity, and difficulty to achieve at the same time, and achieves simple process, excellent heat resistance and oil resistance, and excellent mechanical properties. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

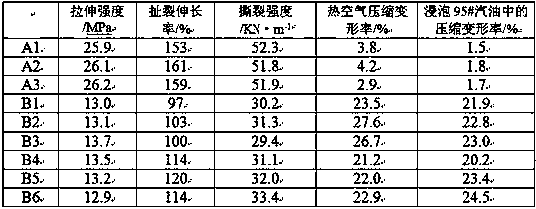

Examples

preparation example Construction

[0014] The invention provides a method for preparing an oil-resistant and heat-resistant automobile engine hollow pipe, comprising:

[0015] 1) Put water glass, graphene and tetrabutyl titanate in dilute sulfuric acid for soaking, washing and drying to obtain modified silica gel;

[0016] 2) Conduct contact reaction with expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution, filter and take filter cake to obtain activation modifier;

[0017] 3) Mix and knead chloroprene rubber, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate, zinc chloride, sodium tungstate, the modified silica gel and the activation modifier , Molding to make oil-resistant and heat-resistant automobile engine hollow tubes.

[0018] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to further improve the mechanical strength, heat resistance and oil resistance of the car engine ...

Embodiment 1

[0032] 1) Mix water glass, graphene, tetrabutyl titanate, and dilute sulfuric acid with a concentration of 2.5% by weight according to a weight ratio of 100:1.5:2.9:400, then stand at 45°C for 6 hours, wash with water, and Dry at 530°C for 1.5h to obtain modified silica gel;

[0033] 2) Mix expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution with a concentration of 25% by weight according to the weight ratio of 100:8:6:180, and contact and react at 85°C for 10h, filter Take filter cake to make activation modifier;

[0034] 3) Neoprene, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate (potassium stearate), zinc chloride, sodium tungstate, modified silica gel and activation modifier Mix according to the weight ratio of 100:59:19:10:13:27:15:5:7:6.5:23:32, knead at 240°C and 4Mpa for 4 hours, and extrude (extrusion molding temperature is 200 ℃) to prepare oil-resistant and heat-resistant automotive engine hol...

Embodiment 2

[0036] 1) Mix water glass, graphene, tetrabutyl titanate, and dilute sulfuric acid with a concentration of 2% by weight according to the weight ratio of 100:1:2.5:300, then stand at 40°C for 5h, wash with water, and Dry at 500°C for 1 hour to obtain modified silica gel;

[0037] 2) Mix expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution with a concentration of 20% by weight according to the weight ratio of 100:5:3:150, and contact and react at 80°C for 8h, filter Take filter cake to make activation modifier;

[0038] 3) Neoprene, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate (sodium stearate), zinc chloride, sodium tungstate, modified silica gel and activation modifier Mix according to the weight ratio of 100:55:17:8:10:22:10:3.5:5:5.5:21:30, knead at 230°C and 3.5Mpa for 3 hours, and extrude (extrusion molding temperature is 190°C) to produce oil-resistant and heat-resistant automotive engine hollow tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com