Welding mechanism of vacuum welding furnace

A vacuum welding furnace and welding mechanism technology, applied in welding equipment, manufacturing tools, metal processing, etc., can solve the problems of slow cooling speed, sheet deformation, low welding efficiency, etc., achieve rapid heating and cooling, and reduce energy consumption , The effect of improving the welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

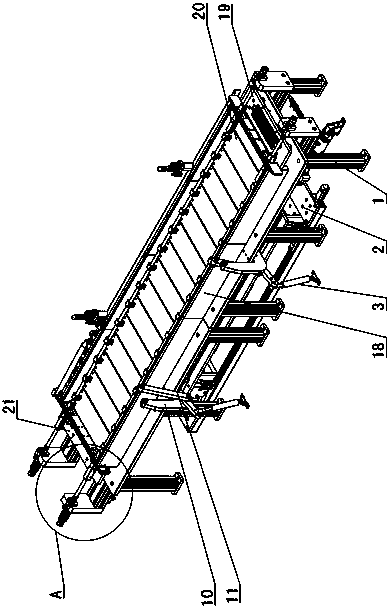

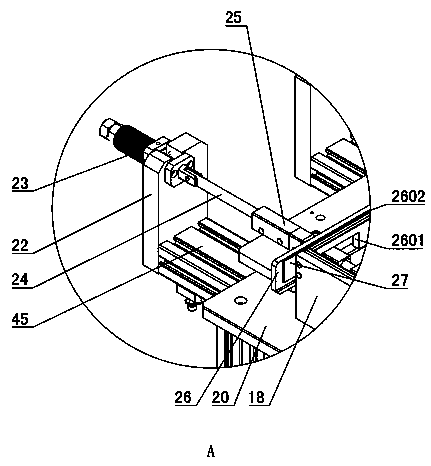

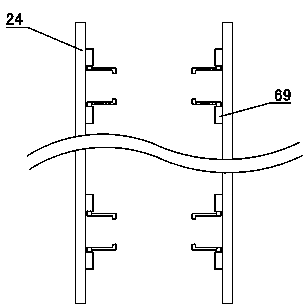

[0057] Such as Figure 1~2 As shown: the lower side of the welding chamber 18 is provided with a transport mechanism 2 , and the welding chamber 18 is arranged on the upper side of the frame 1 . The conveying mechanism 2 comprises a conveying rod 24 and a lifting mechanism, a translation mechanism and an opening and closing mechanism arranged on the lower side of the welding chamber 18. The middle part of the conveying rod 24 is arranged in the welding chamber 18, and the two ends of the welding chamber 18 are closed by end caps 26. And both sides of each end cover 26 are all provided with carrying port 2601, and carrying rod 24 is arranged horizontally along the length direction of welding chamber 18, and two carrying rods 24 are symmetrically arranged on both sides of welding chamber 18, and each carrying rod 24 The two ends of each pass through the port 2601 of the end cover 26 and stretch out. The lower side of the welding chamber 18 is horizontally provided with a transp...

Embodiment 2

[0090] The difference between Embodiment 2 and Embodiment 1 is that the supporting part is directly installed on the transport rod 24, the two ends of the heating plate 30 are provided with a heating plate relief port 3001, and the two ends of the cooling plate 28 are provided with a cooling plate relief port 2801. The support part supports the material sheet through both ends of the material sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com