Preparation method of nickel-cobalt-aluminum ternary precursor and preparation method of positive electrode material

A positive electrode material, nickel-cobalt-aluminum technology, applied in the field of preparation of nickel-cobalt-aluminum ternary precursors and positive electrode materials, can solve problems such as poor structural stability, low discharge capacity, complicated process, etc., to improve discharge specific capacity and cycle performance , high specific surface area and porous characteristics, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a nickel-cobalt-aluminum ternary precursor, comprising the following steps:

[0024] 1) nickel nitrate, cobalt nitrate, aluminum nitrate are dissolved in deionized water to prepare an aqueous solution, the total concentration of nickel, cobalt and aluminum in the aqueous solution is 0.5~2.5mol / L, Ni:Co:Al molar ratio is x: y: (1-x-y), where 0.7≤x≤0.8, 0.15≤y≤0.25;

[0025] 2) ultrasonically disperse the aqueous solution for 5 min, then add isopropanol and stir at room temperature for 1 h to prepare a mixed metal salt solution, add a low-carbon alcohol solvent to the mixed metal salt solution and stir at room temperature for 1 h, Prepare mixed reaction solution;

[0026] 3) Add the mixed reaction liquid into the reaction kettle for reaction, react continuously at 120-140°C for 6-12h, then cool to room temperature, centrifuge to obtain the precipitate, wash and dry in vacuum at 80°C for 24h, A nickel-cobalt-aluminum ternary ...

Embodiment 1

[0034] In this embodiment, a method for preparing a nickel-cobalt-aluminum ternary precursor comprises the following steps: respectively weighing 0.008 mol of nickel nitrate and 0.0015 mol of Cobalt nitrate and 0.0005 mol of aluminum nitrate were dissolved in 10 mL of deionized water to prepare an aqueous solution. The aqueous solution was ultrasonically dispersed for 5 minutes, and then 50 mL of isopropanol was added and magnetically stirred at room temperature for 1 hour to prepare a mixed metal salt solution. 15 mL of methanol was added to the mixed metal salt solution and magnetically stirred at room temperature for 1 h to prepare a mixed reaction solution.

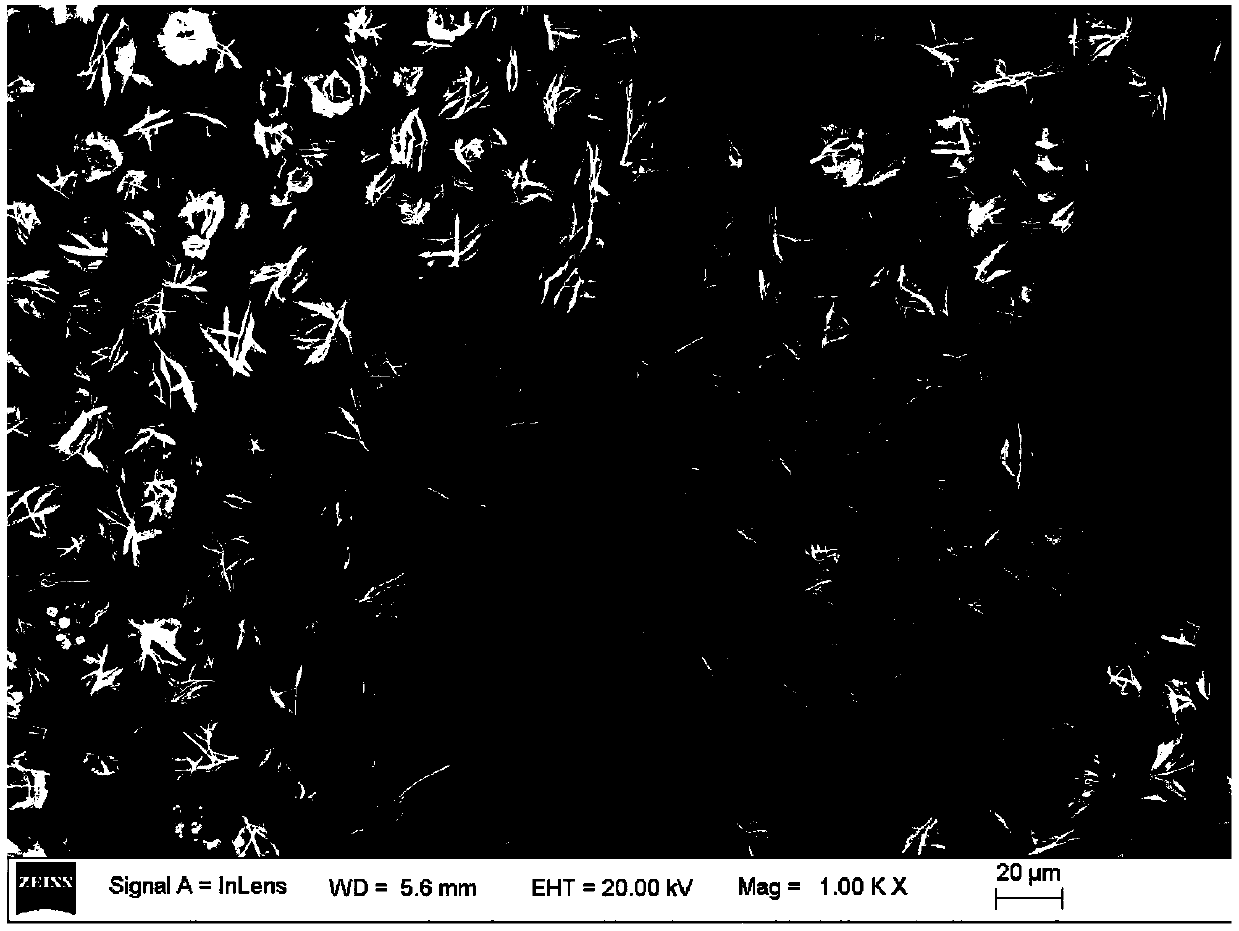

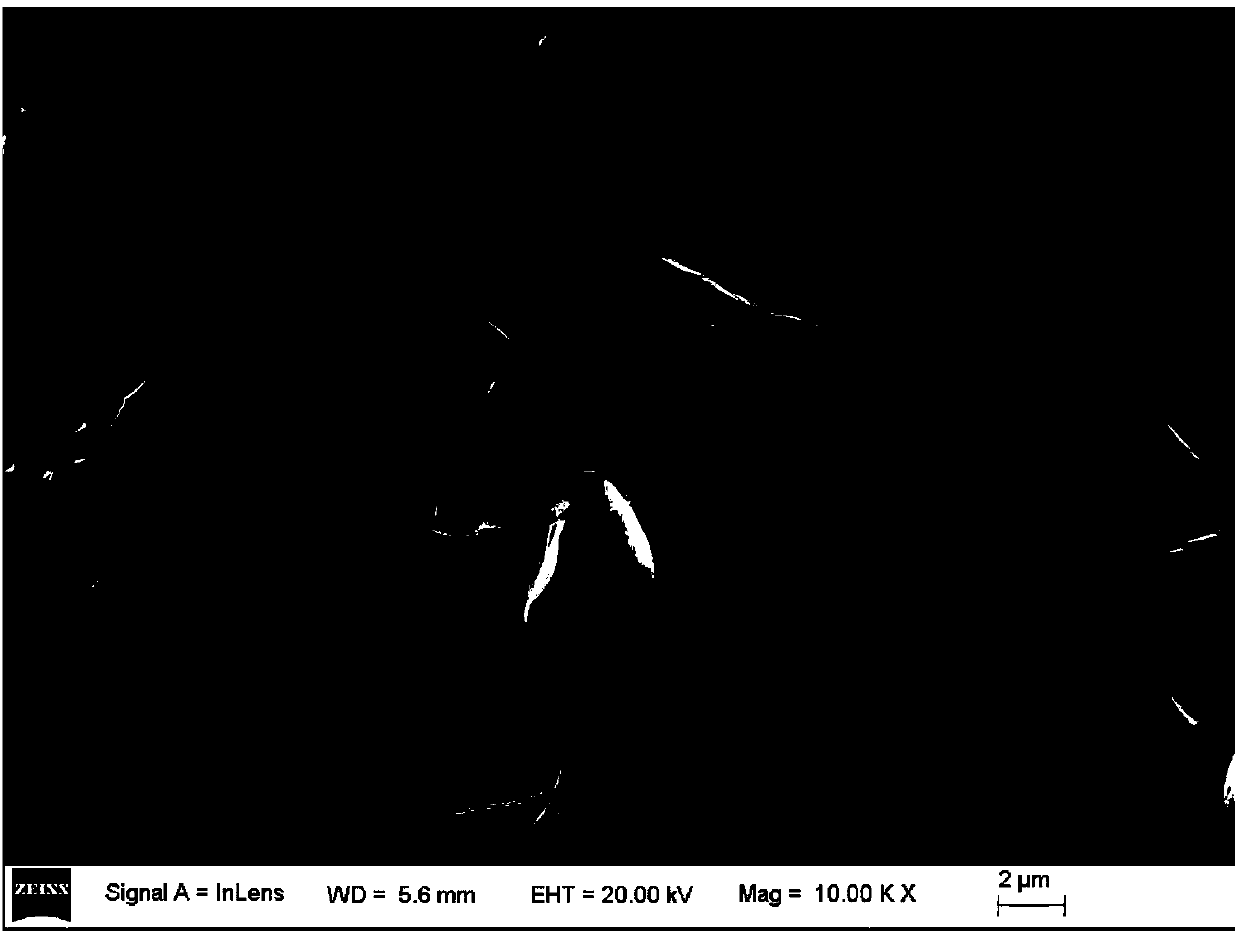

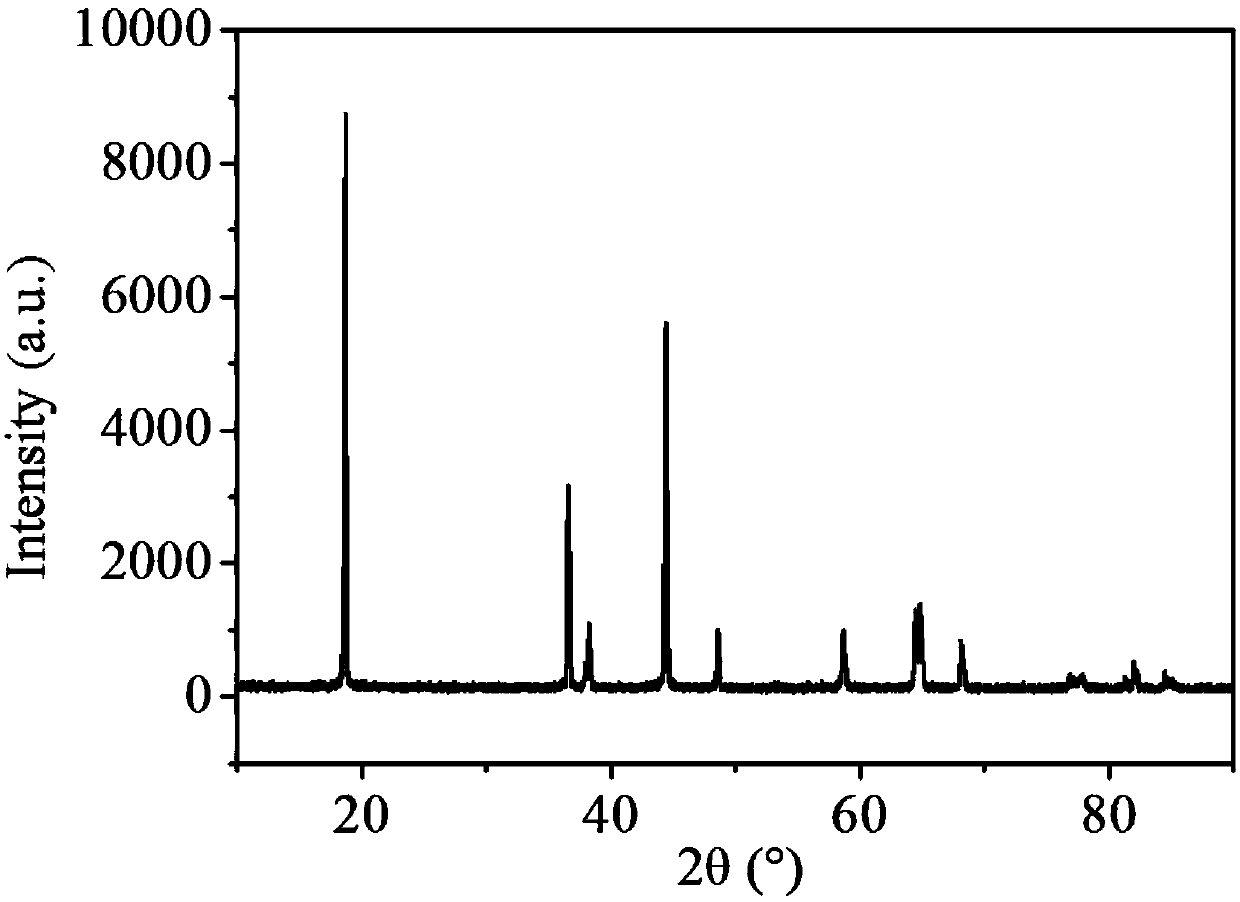

[0035] The mixed reaction solution was added to a 100mL reaction kettle for reaction, and the reaction was continued at 120°C for 8h, then cooled to room temperature, and centrifuged to obtain a precipitate, which was washed three times with deionized water and absolute ethanol alternately. Vacuum-dried at 80°C for 24...

Embodiment 2

[0038]In this embodiment, a method for preparing a nickel-cobalt-aluminum ternary precursor comprises the following steps: Weighing 0.007 mol of nickel nitrate and 0.002 mol of Ni Cobalt nitrate and 0.001 mol of aluminum nitrate were dissolved in 5 mL of deionized water to prepare an aqueous solution. The aqueous solution was ultrasonically dispersed for 5 minutes, and then 60 mL of isopropanol was added and magnetically stirred at room temperature for 1 hour to prepare a mixed metal salt solution. 10 mL of methanol was added to the mixed metal salt solution and magnetically stirred at room temperature for 1 h to prepare a mixed reaction solution.

[0039] The mixed reaction solution was added to a 100mL reaction kettle for reaction, and the reaction was continued at 140°C for 6h, then cooled to room temperature, and centrifuged to obtain a precipitate, which was washed three times with deionized water and absolute ethanol alternately. Vacuum-dried at 80°C for 24 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com