Convenience type fast die erecting auxiliary mechanism

An auxiliary mechanism and a convenient technology, which is applied in the field of convenient rapid frame formwork auxiliary mechanism, can solve the problems of time-consuming and labor-intensive, low production efficiency, long production time, etc., and achieve the effects of accurate positioning position, stable structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

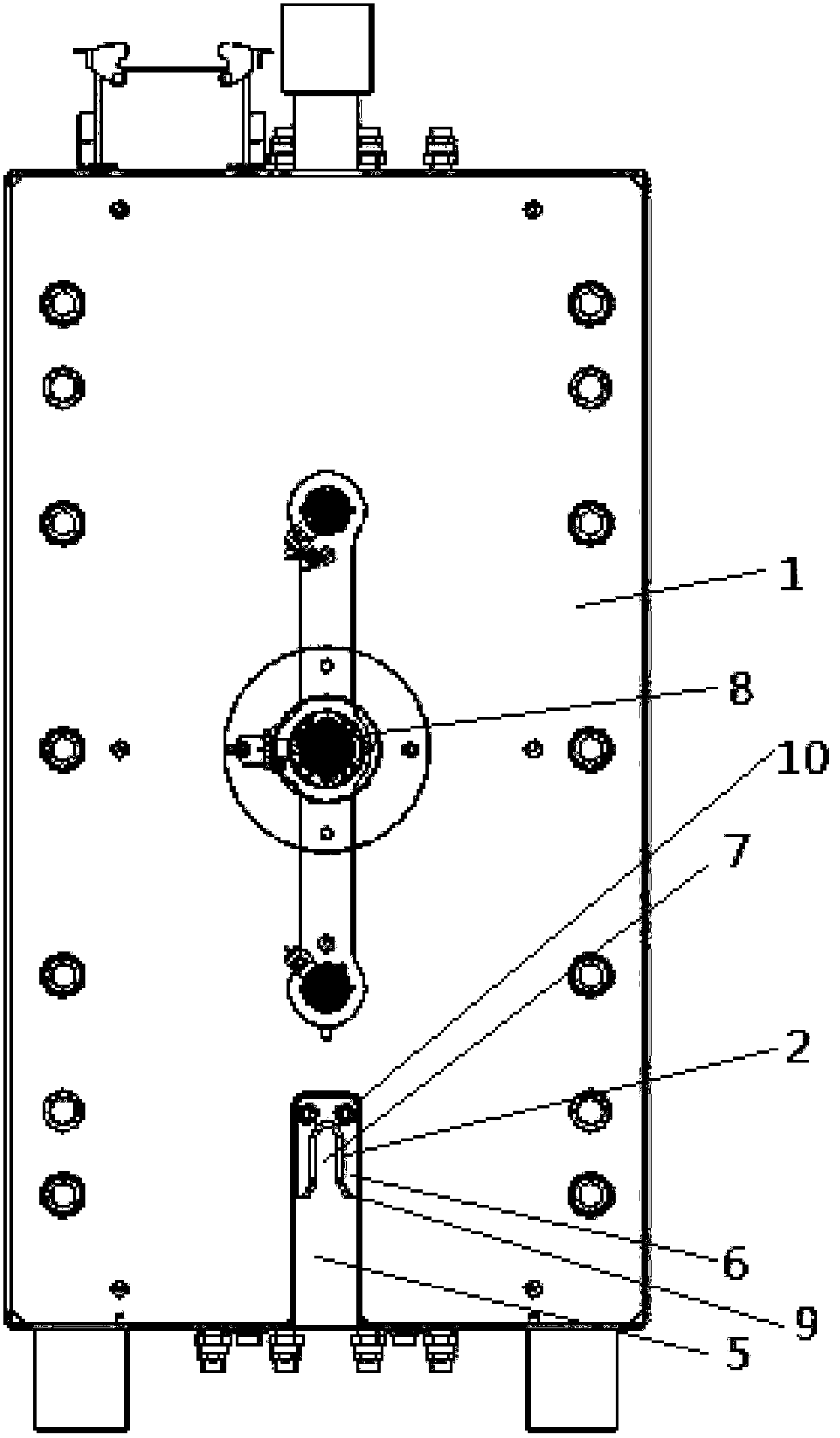

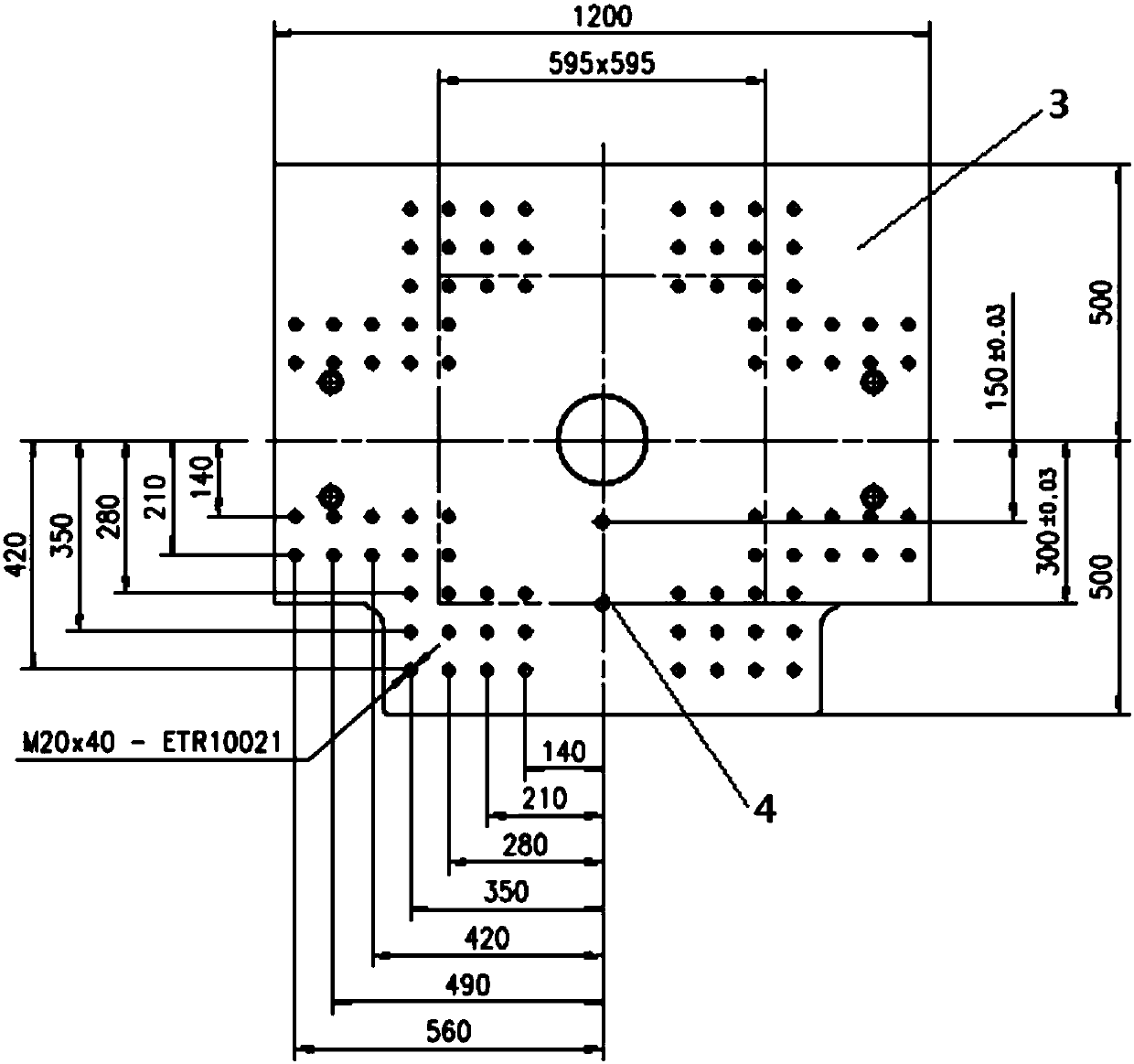

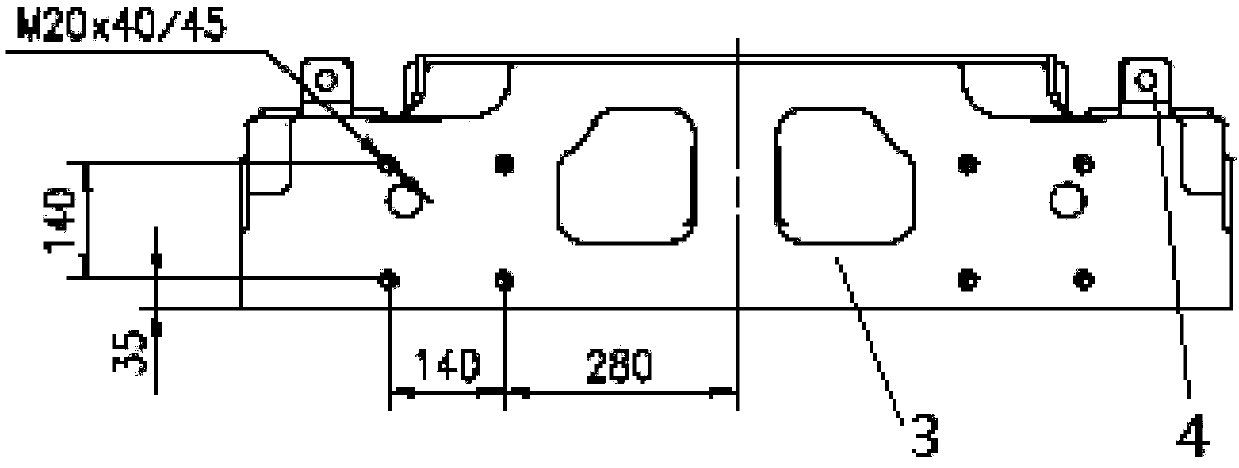

[0022] Such as Figure 1~Figure 5 As shown, a convenient quick-set mold auxiliary mechanism includes a positioning block 2 located on a mold 1 and a positioning pin 4 located on an injection molding machine 3 for use in cooperation with the positioning block 2, and the lower part of the mold 1 Grooves 5 are arranged on the left and right sides of the surface, and the positioning block 2 is arranged in the groove 5. The positioning block 2 includes a positioning block body 6, and the positioning block body 6 is provided with holes for passing through the positioning block. The U-shaped through hole 7 of the needle 4, the opening direction of the U-shaped through hole 7 and the opening direction of the groove 5 are all facing away from the machine filling nozzle 8 of the mold 1, and the opening direction of the U-shaped through hole 7 The end is an involute bevel 9. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com