Method for synthesizing PODE (polyoxymethylene dimethyl ethers)

A technology of polyoxymethylene dimethyl ether and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low product selectivity, etc. The effect of good rate and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

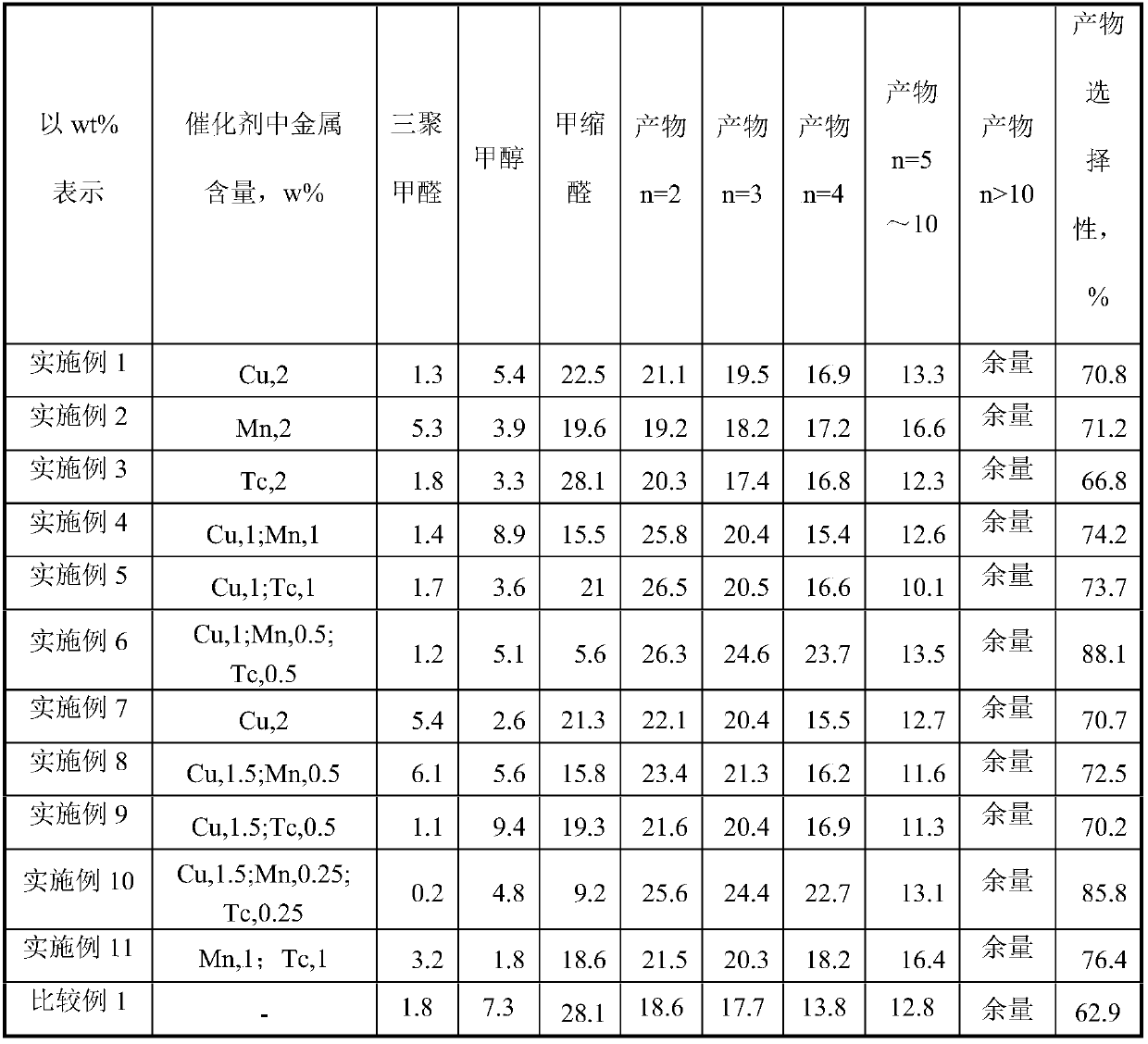

Examples

Embodiment 1

[0032] 1. Preparation of catalyst

[0033] Sodium sulfonate type polystyrene cation exchange resin 7320 is washed with deionized water until clear water flows out, then soaked four times with 4w% hydrochloric acid, each use is equivalent to 10 times the dry weight of sodium sulfonate type polystyrene cation exchange resin 7320 4w% hydrochloric acid, soaked for 4 hours each time, then washed with deionized water until the eluate was free of chloride ions, and dried at 60°C to obtain a sulfonic acid polystyrene cation exchange resin with a total exchange capacity of 4.10 mmol / g. Get the sulfonic acid type polystyrene cation exchange resin that is equivalent to dry base resin 98 grams and 300ml contain Cu and be 2 grams of Cu(OH) 2 The aqueous suspensions were mixed, 1 drop of glacial acetic acid was added, mixed, left standing at room temperature for 24 hours, and dried in a vacuum drying oven to a constant weight to obtain a catalyst with a Cu content of 2w%.

[0034] 2. Synt...

Embodiment 2

[0037] 1. Preparation of catalyst

[0038] Sodium sulfonate type polystyrene cation exchange resin 7320 is washed with deionized water until clear water flows out, then soaked four times with 4w% hydrochloric acid, each use is equivalent to 10 times the dry weight of sodium sulfonate type polystyrene cation exchange resin 7320 4w% hydrochloric acid, soaked for 4 hours each time, then washed with deionized water until the eluate was free of chloride ions, and dried at 60°C to obtain a sulfonic acid polystyrene cation exchange resin with a total exchange capacity of 4.10 mmol / g. Get the sulfonic acid type polystyrene cation exchange resin that is equivalent to 98 grams of dry base resin, under nitrogen protection, be 2 grams of Mn(OH) containing Mn with 300ml 2 The aqueous suspensions were mixed, 1 drop of glacial acetic acid was added, mixed, left to stand at room temperature for 24 hours, and dried in a vacuum oven to constant weight to obtain a catalyst with a Mn content of ...

Embodiment 3

[0042] 1. Preparation of catalyst

[0043] Sodium sulfonate type polystyrene cation exchange resin 7320 is washed with deionized water until clear water flows out, then soaked four times with 4w% hydrochloric acid, each use is equivalent to 10 times the dry weight of sodium sulfonate type polystyrene cation exchange resin 7320 4w% hydrochloric acid, soaked for 4 hours each time, then washed with deionized water until the eluate was free of chloride ions, and dried at 60°C to obtain a sulfonic acid polystyrene cation exchange resin with a total exchange capacity of 4.10 mmol / g. Get the sulfonic acid type polystyrene cation exchange resin equivalent to 98 grams of dry base resin, under nitrogen protection, with 300ml of Tc containing Tc is 2 grams of Tc (OH) 2 Mix the aqueous suspensions, add 1 drop of glacial acetic acid, mix, let stand at room temperature for 24 hours, and dry to constant weight in a vacuum oven to prepare a catalyst with a Tc content of 2w%.

[0044] 2. Syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com