Method for producing grain oriented electrical steel strip and grain oriented electrical steel strip

A technology of electrical steel strip and grain orientation, which is applied in the direction of metal material coating process, instrument, analysis material, etc., can solve the problem that the oxide layer cannot be given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

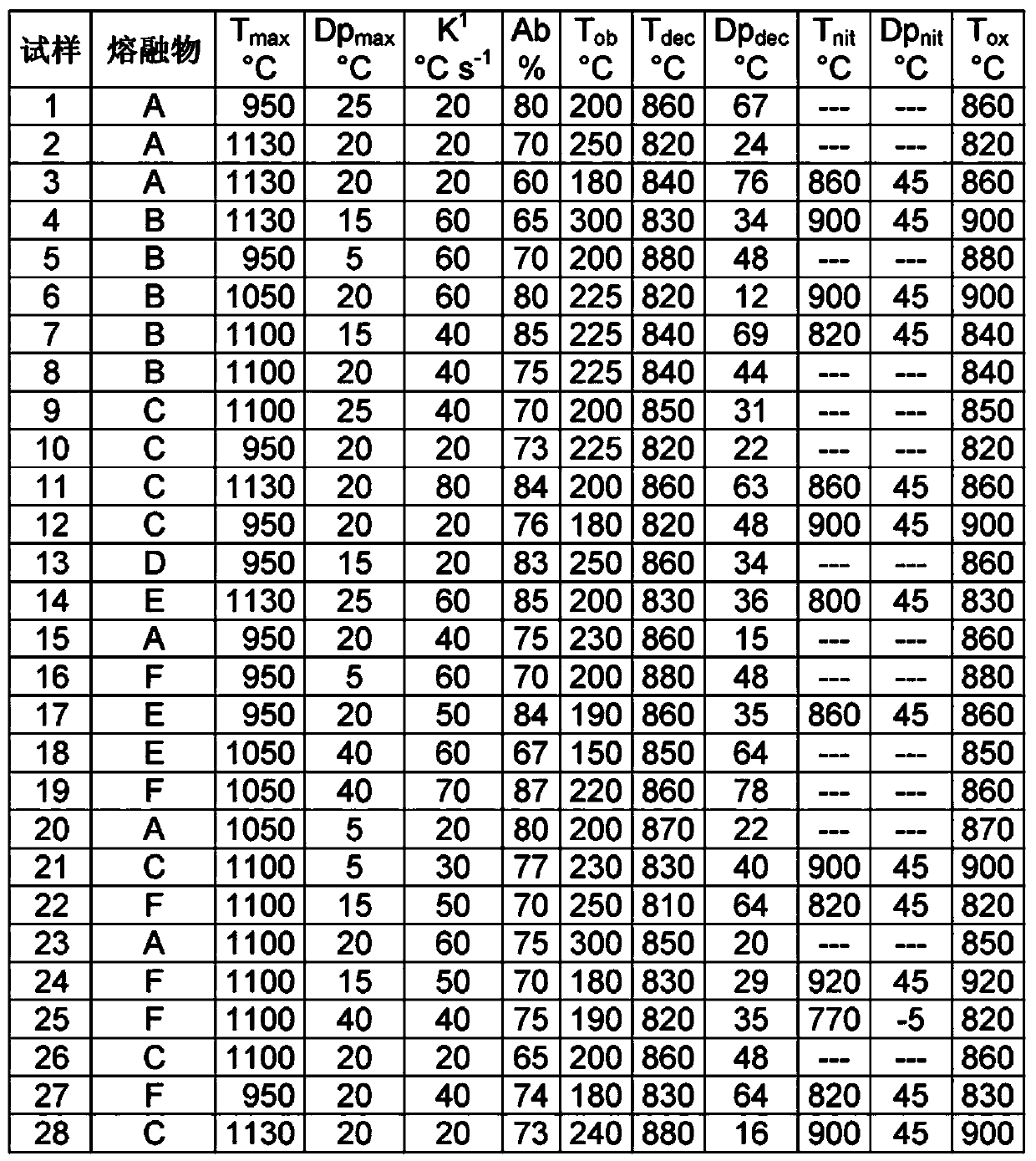

[0086] Melts A-F having the compositions shown in Table 1 were melted and cast into 65 mm strips from which thin slabs were separated as prefabricated products.

[0087] In 28 trials, cold-rolled strip for the production of grain-oriented electrical steel strip was produced from thin slabs in the manner described below.

[0088] After reheating to a reheating temperature of typically 1170° C., the thin slab is hot rolled into a hot strip having a thickness of typically 2.3 mm, which is then wound into a coil. The winding temperature here is usually 540°C.

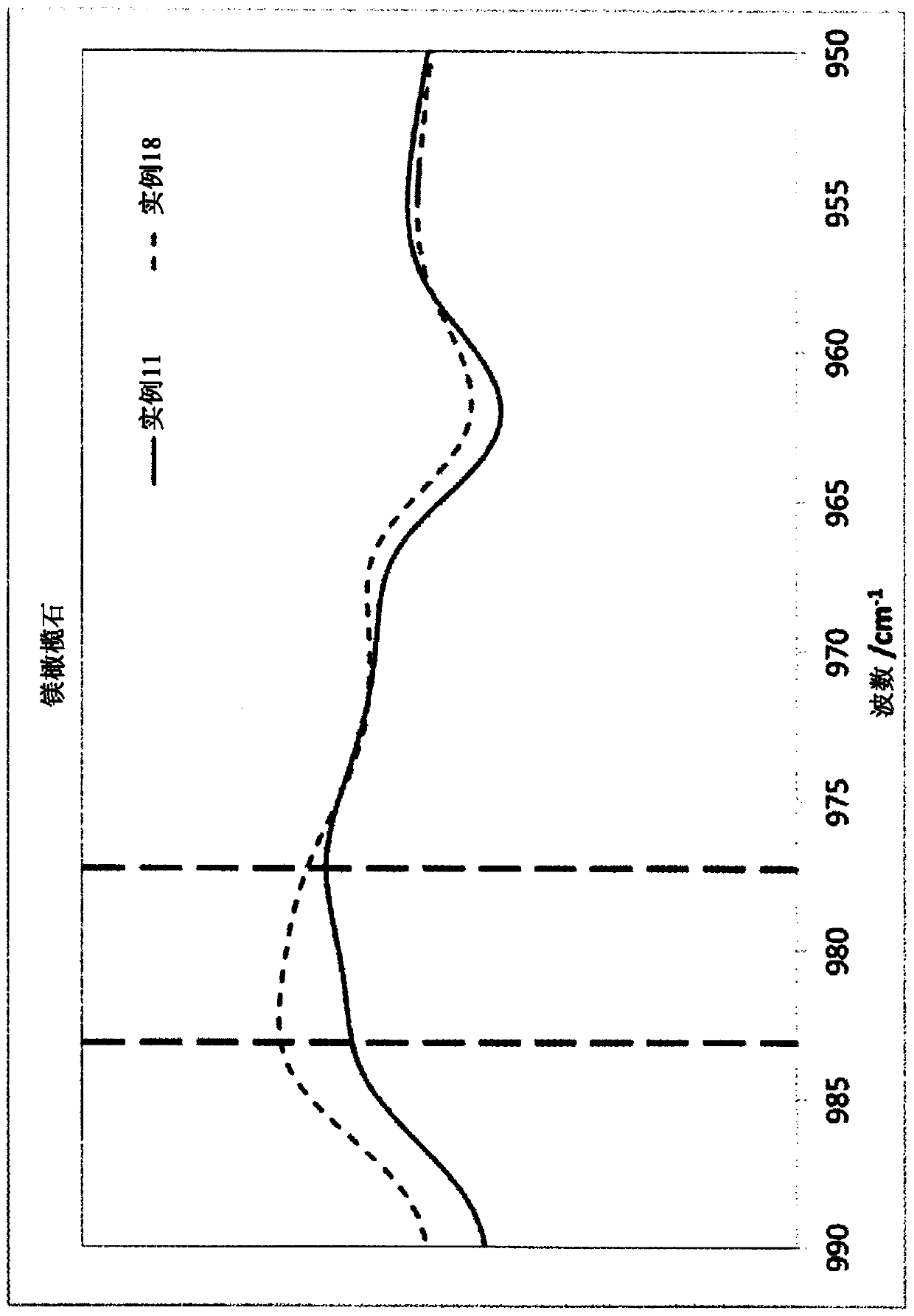

[0089] The individual hot-rolled strips are then subjected to a hot-rolled strip annealing in which the individual hot-rolled strips are heated at a maximum temperature T max , with Dp max Fully heated in the atmosphere of the maximum dew point temperature and each hot-rolled strip is cooled to room temperature at a cooling rate K after the hot-rolled strip is processed.

[0090] The hot-rolled strip is then cold-rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com