Quick coating withdrawing equipment

A coating and equipment technology, applied in the field of rapid coating removal equipment, can solve the problems of inability to clean the coating, poor spraying, low efficiency, etc., and achieve the effect of improving efficiency and widening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and the drawings, and the content mentioned in the embodiments does not limit the present invention.

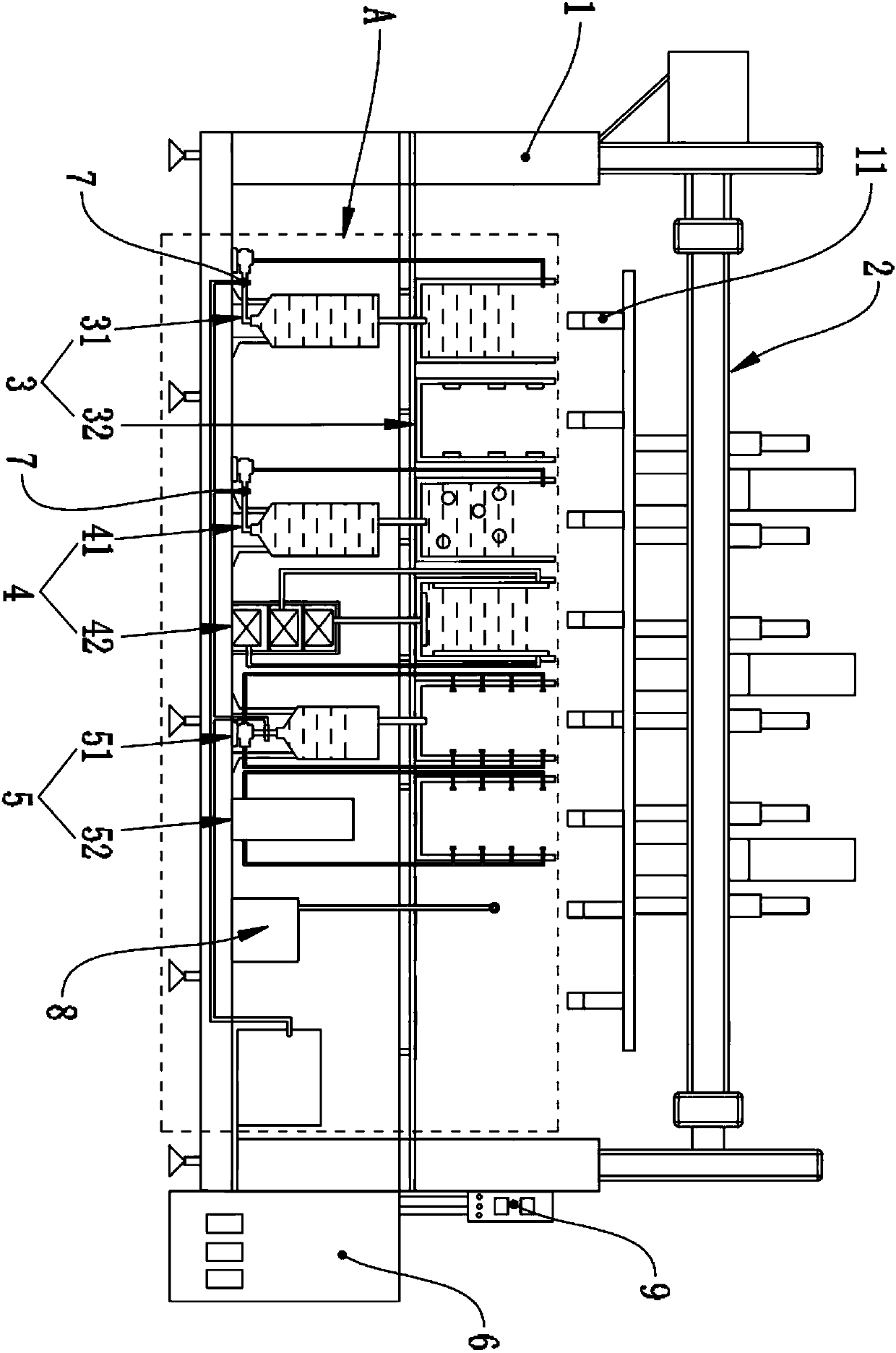

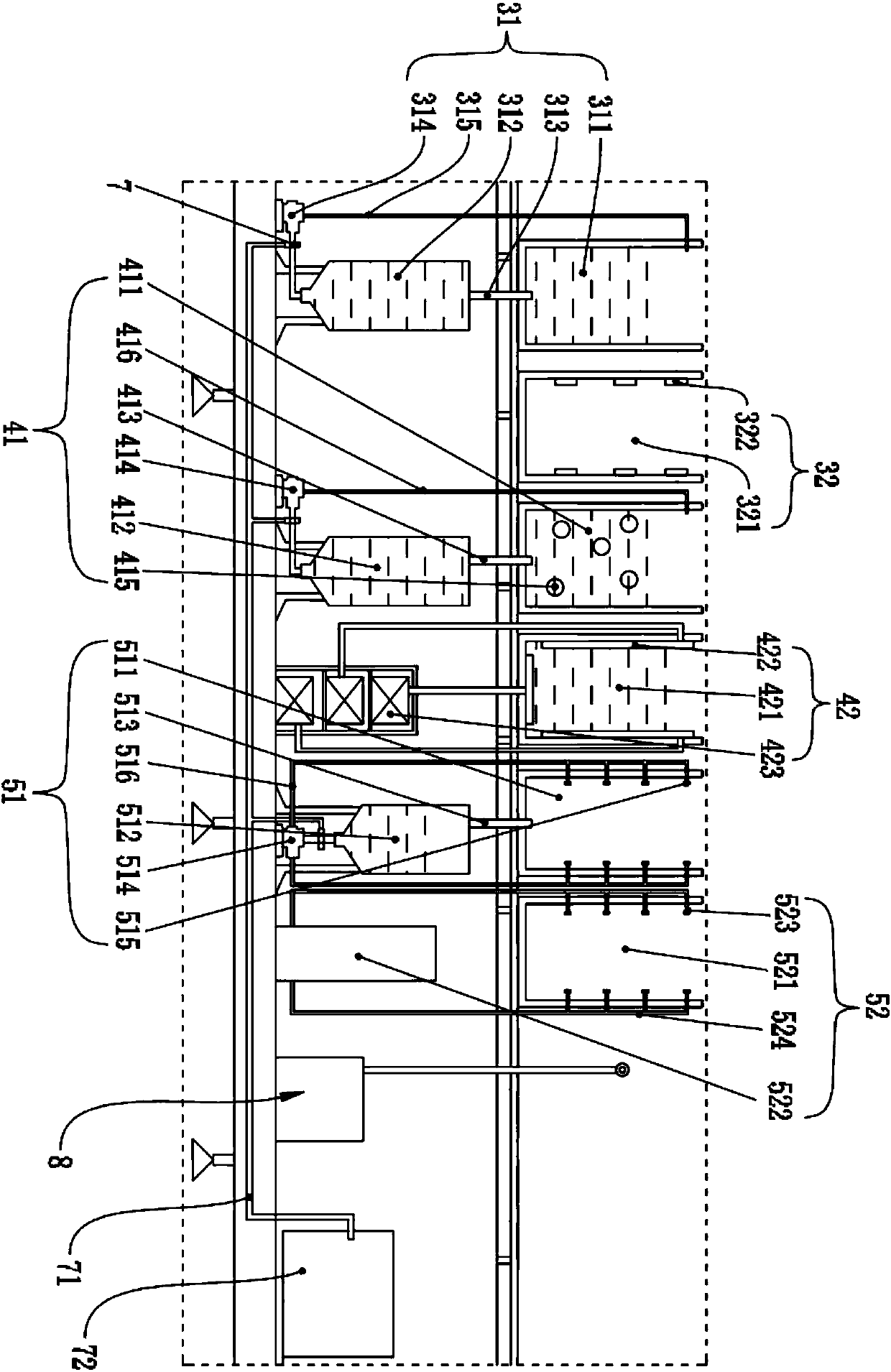

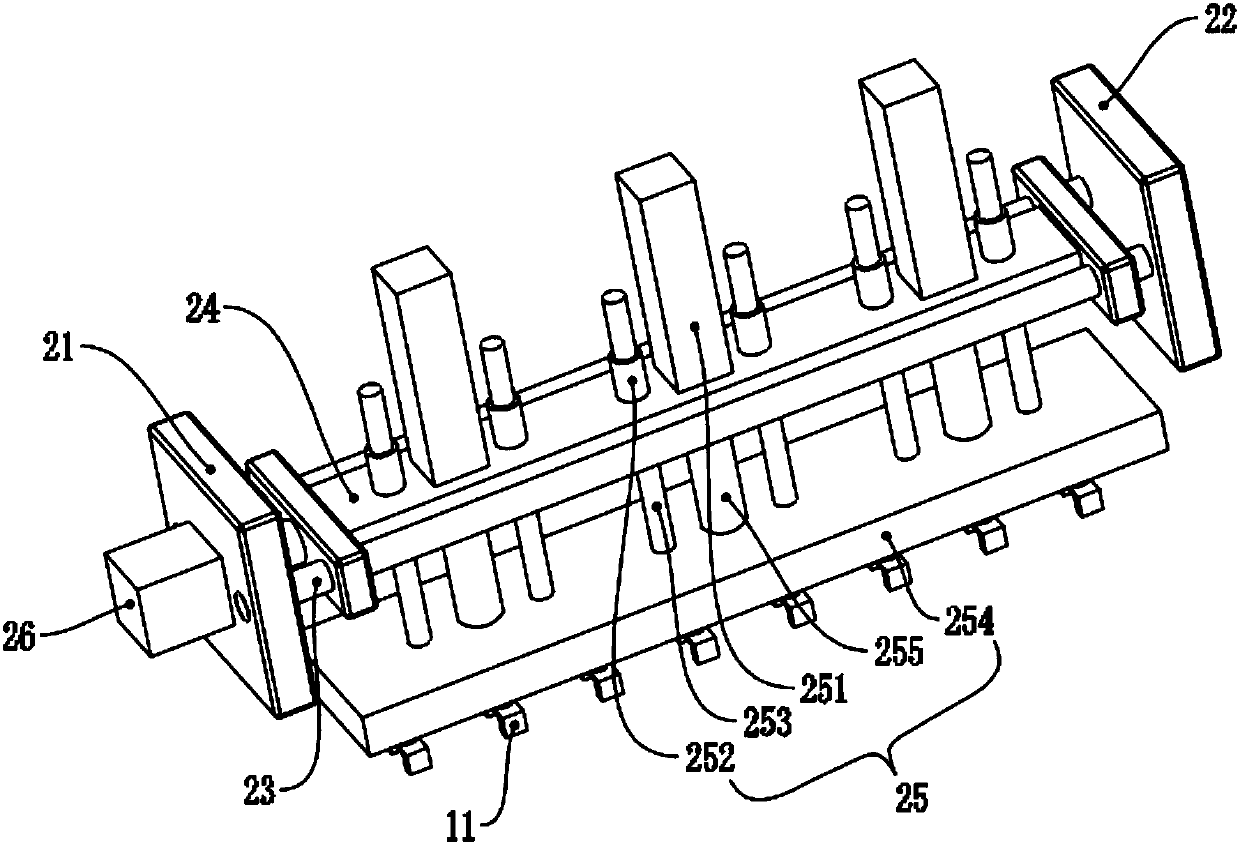

[0023] Such as figure 1 As shown, the rapid decoating equipment proposed by the present application includes a frame 1, a picking member 11 movably arranged on the frame 1, and a first drive assembly 2 for driving the picking member 11 to move. The first device 3 is used to perform thermal expansion and contraction treatment on the external workpiece picked up by the pickup 11, and the second device 4 is installed in the frame 1 and used to perform water bath decoating treatment on the workpiece processed by the first device 3 The decoating equipment also includes an electric control box 6 and a handheld box 9; the first drive assembly 2, the first device 3, the second device 4 and the handheld box 9 are respectivel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap