High-strength safety type drill pipe

A safe and high-strength technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of drill pipe joint failure accidents, affecting the drilling effect of the drill pipe, and low strength of the drill pipe, so as to improve the overall strength and increase the strength of the drill pipe. Drilling effect, effect of sulfur resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

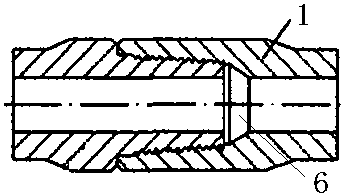

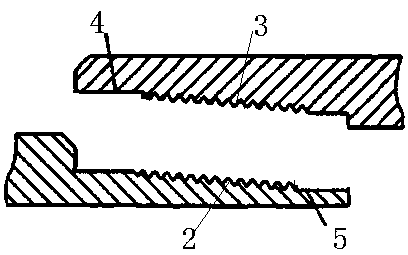

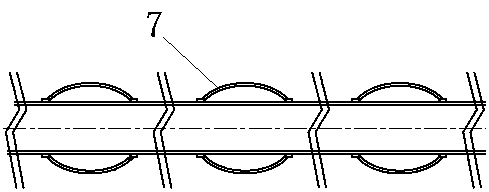

[0016] See Figure 1 to Figure 3 , The present invention relates to a high-strength safety drill rod, including a drill rod body 1, the outer thread 2 is provided on the outer periphery of the small end of the male buckle of the drill rod body 1, and the inner wall of the large end of the female buckle of the drill rod body 1 is provided with inner Thread 3, the external thread 2 of two adjacent drill rods meshes with the internal thread 3, so that the two drill rods are connected, and the drill rod body 1 has stepped surfaces on the upper and lower ends of the external thread 2 and the upper and lower ends of the internal thread 3 , Wherein the steps at the lower end of the external thread 2 and the lower end of the internal thread 3 are the main shoulder 4, and the steps at the upper end of the external thread 2 and the upper end of the internal thread 3 are the secondary shoulders 5. The drill rod body 1 is sleeved with a plurality of springs to center The spring centralizer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap