A liquid ring pump

A liquid ring pump and housing technology, applied in the field of liquid ring pumps, can solve the problems of multi-working conditions and inconvenient adjustment, and achieve the goals of ensuring stability and fluency, improving use efficiency, improving work performance and work reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

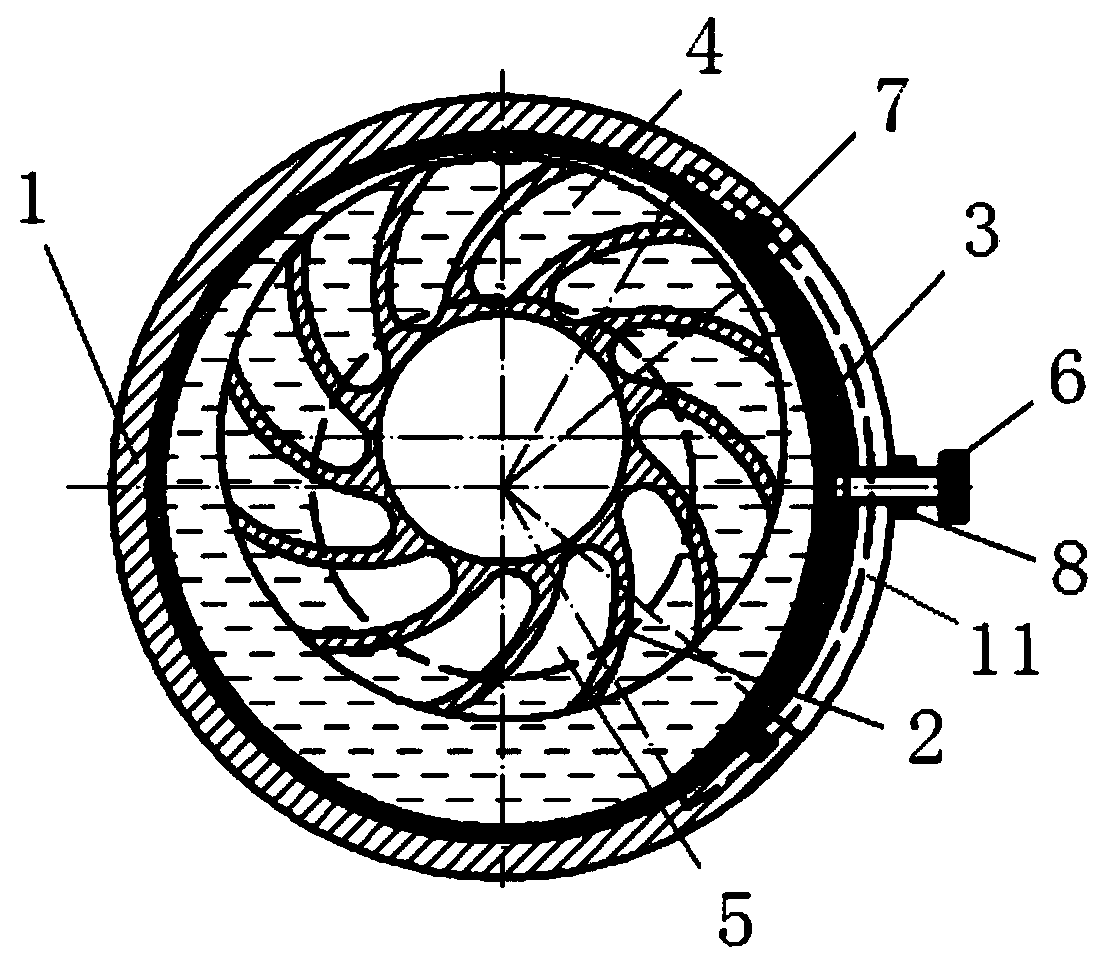

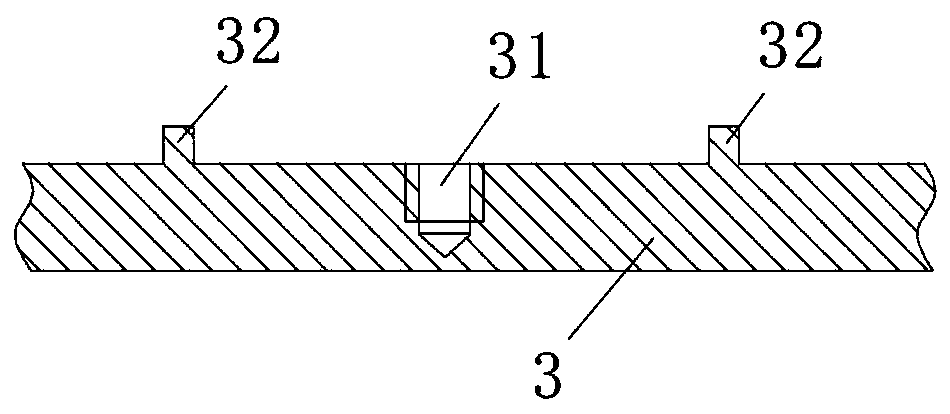

[0021] combine figure 1 As shown, the liquid ring pump of the present invention includes a housing 1 , an impeller 2 and an adjusting sleeve 3 . Wherein, the impeller 2 is located inside the casing 1 and is arranged eccentrically with the casing 1 . The adjusting sleeve 3 is an annular structure located between the housing 1 and the adjusting sleeve 3 , and the adjusting sleeve 3 can rotate relative to the housing 1 along the circumferential direction. At the same time, the outer surface of the adjustment sleeve 3 is in contact with the inner surface of the housing 1, and the wall thickness of the adjustment sleeve 3 is designed to be non-equal thickness along the circumferential direction, that is, the distance between the inner surface of the adjustment sleeve 3 and its central axis, 1. The circumferential direction of the inner surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com