Full automatic ball valve assembly equipment and method

An assembly equipment, fully automatic technology, applied in the direction of valve devices, mechanical equipment, metal processing equipment, etc., can solve the problems of low assembly efficiency, large labor costs, product processing delays, etc., to save labor costs, improve assembly efficiency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0058] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

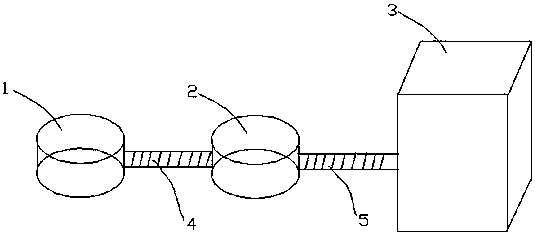

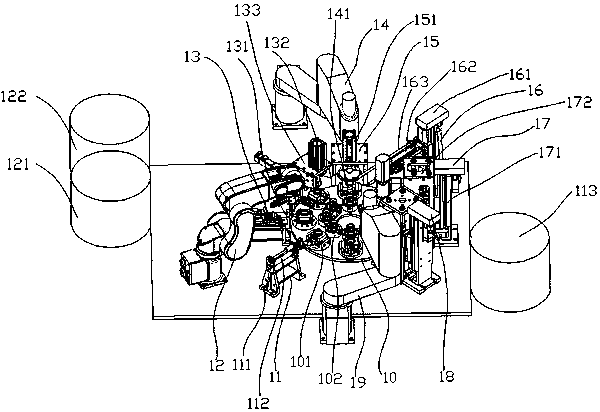

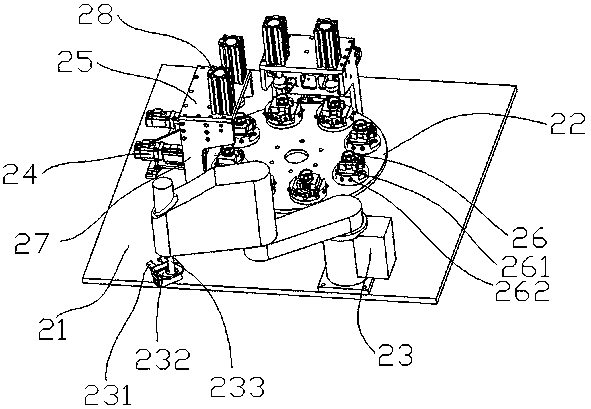

[0059] See Figure 1 to Figure 7 , An embodiment of the present invention is a fully automatic ball valve assembly device including a ball valve assembly device 1, a ball valve gas measurement device 2, a ball valve mounting handle, and a label device 3.

[0060] The ball valve assembly equipment 1 is connected to the ball valve gas measuring device 2 through the first conveying device 4; the ball valve gas measuring device 2 is connected to the ball valve mounting handle and the labeling device 3 through the second conveying device 5.

[0061] The process flow of the embodiment of the present invention is:

[0062] (1) Ball valve assembly equipment 1 is used to assemble the valve body, bonnet, valve stem, valve ball, side screw c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap