Preparation method of manganese magnesium borate-doped magnesium ion battery positive electrode material

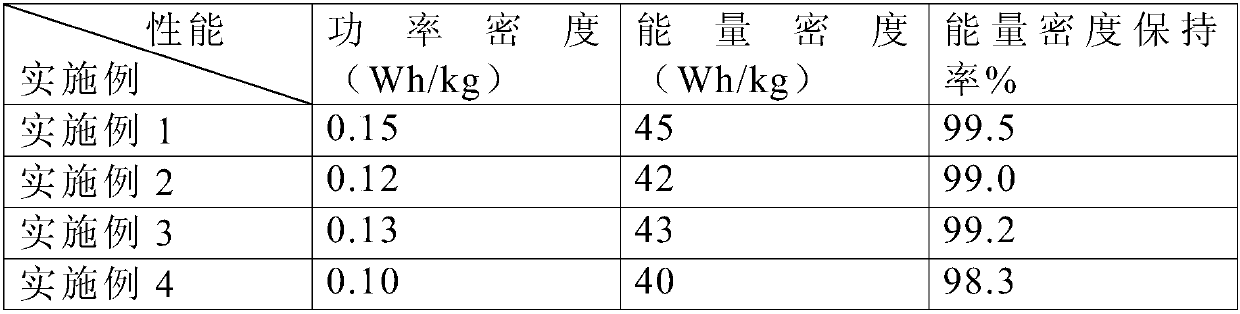

A technology of manganese borate magnesium magnesium ion and battery positive electrode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems that magnesium batteries cannot meet the use environment, and achieve large-scale industrial production, good cycle stability, and low volume The effect of rate of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

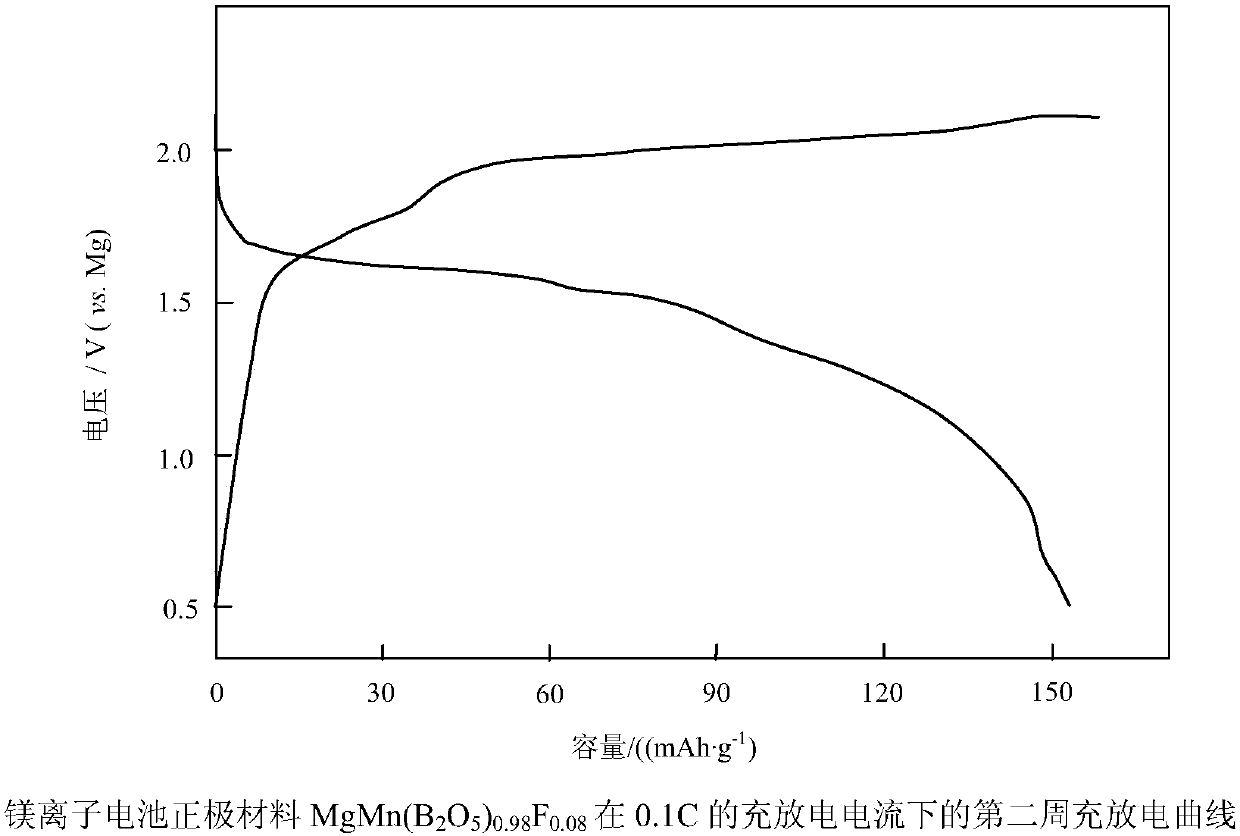

Embodiment 1

[0031] Pretreatment: Weigh the raw materials according to the composition of the positive electrode material of the battery, including 1.0mol magnesium nitrate, 1.0mol manganese nitrate, 0.08mol ammonium fluoride, 1.96mol trimethyl borate, and dissolve magnesium nitrate, manganese nitrate and ammonium fluoride respectively Prepare a solution with a concentration of 0.5 mol / l in absolute ethanol, dissolve trimethyl borate in methanol to prepare a solution with a concentration of 0.25 mol / l, then mix the dissolved solutions and stir evenly to obtain a mixed solution.

[0032] Precursor preparation: add deionized water with a volume ratio of 1:1 to the mixed solution, stir vigorously to obtain a jelly-like mixture, then put the jelly-like mixture into a stainless steel tank lined with polytetrafluoroethylene, heat up Heat it at 200°C for 48 hours to react to obtain a colloidal precipitate and dry it. Then, under the protection of an inert gas, pre-calcine at 300°C for 8 hours to o...

Embodiment 2

[0036] Pretreatment: Weigh the raw materials according to the composition of the positive electrode material of the battery, including 1.0mol magnesium nitrate, 1.0mol manganese nitrate, 0.09mol ammonium fluoride, 1.98mol trimethyl borate, and dissolve magnesium nitrate, manganese nitrate and ammonium fluoride respectively Prepare a solution with a concentration of 0.5 mol / l in absolute ethanol, dissolve trimethyl borate in methanol to prepare a solution with a concentration of 0.25 mol / l, then mix various dissolved solutions and stir evenly to obtain a mixed solution.

[0037] Precursor preparation: add deionized water with a volume ratio of 1:1 to the mixed solution, stir vigorously to obtain a jelly-like mixture, then put the jelly-like mixture into a stainless steel tank lined with polytetrafluoroethylene, heat up Heat it at 160°C for 72 hours to obtain a colloidal precipitate and dry it. Then, under the protection of an inert gas, pre-calcine at 250°C for 8 hours to obtain a...

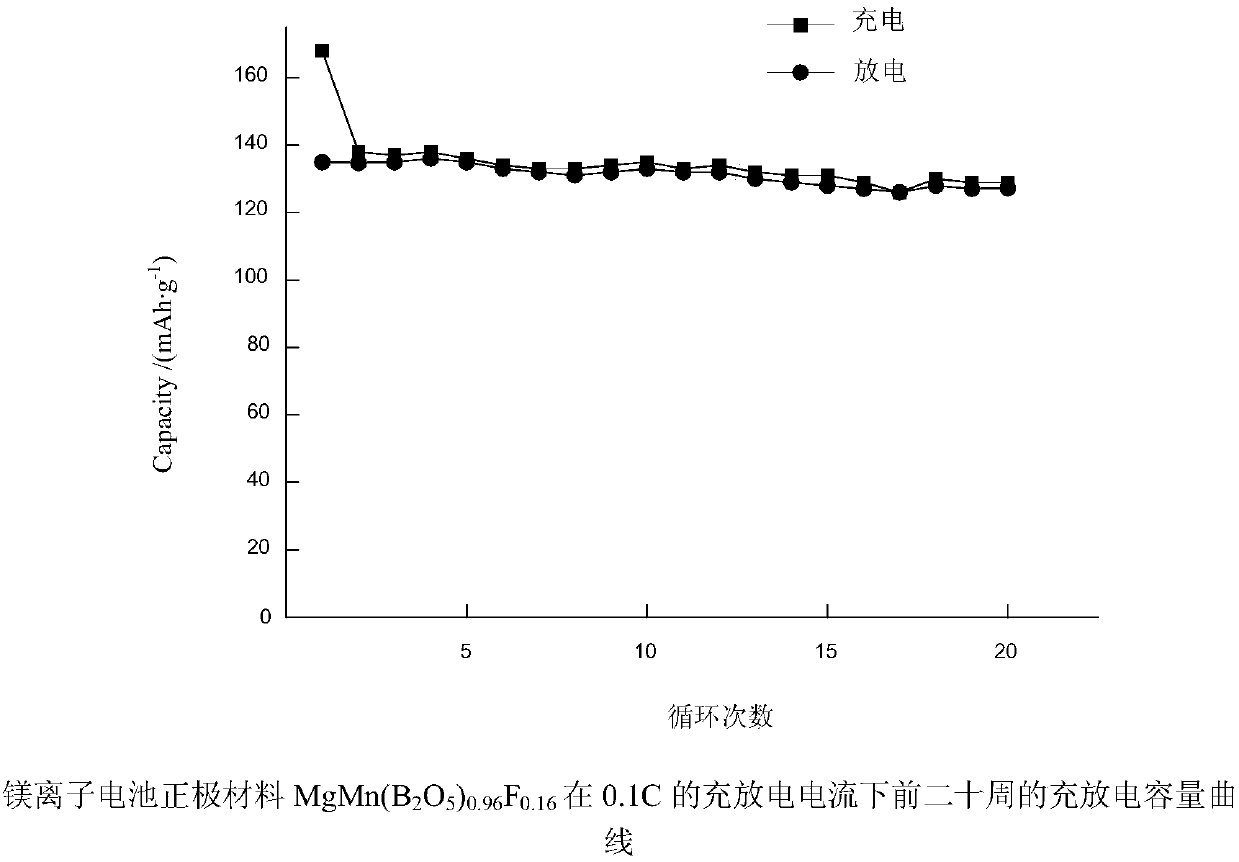

Embodiment 3

[0041] Pretreatment: Weigh the raw materials according to the composition of the positive electrode material of the battery, including 1.0mol magnesium nitrate, 1.0mol manganese nitrate, 0.16mol ammonium fluoride, 1.92mol trimethyl borate, and dissolve magnesium nitrate, manganese nitrate and ammonium fluoride respectively Prepare a solution with a concentration of 0.5 mol / l in absolute ethanol, dissolve trimethyl borate in methanol to prepare a solution with a concentration of 0.25 mol / l, then mix various dissolved solutions and stir evenly to obtain a mixed solution.

[0042] Precursor preparation: add deionized water with a volume ratio of 1:1 to the mixed solution, stir to obtain a jelly-like mixture, then put the jelly-like mixture into a stainless steel tank lined with polytetrafluoroethylene, and heat up to 250°C, heat preservation for 12h to react to obtain a colloidal precipitate and dry it, then pre-calcine at 350°C for 4h under the protection of an inert gas to obtai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap