Modified perfluorocarbon battery and methods for preparing positive electrode pieces and positive electrode materials for modified perfluorocarbon battery

A technology of permanent fluorinated carbon and positive electrode materials, applied in the field of preparation of modified carbon fluorinated batteries and their positive electrode sheets and positive electrode materials, can solve large energy loss, large discharge/charge potential difference, poor cycle stability, etc. problems, to achieve the effect of improved reactivity, simple modification method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a modified carbon fluoride cathode material, which comprises the following steps: first dispersing the carbon fluoride material in a solvent to form a dispersion liquid; then heating the dispersion liquid, and keeping the heating reaction for a period of time, During this process, the method is kept stirring; after the heating reaction is completed, the method is ultrasonicated, dried, and the solvent is evaporated to prepare the modified carbon fluoride cathode material.

[0023] Preferably, the fluorinated carbon material is one or more of fluorinated graphite, fluorinated carbon fiber, fluorinated carbon nanodisc, fluorinated coke or fluorinated mesocarbon sphere; the fluorinated carbon material The fluorocarbon molar ratio is 0.33-1.2.

[0024] Preferably, the solvent is one or more of N-methylpyrrolidone, isopropanol, acetone or N,N-dimethylformamide.

[0025] Preferably, the concentration of the carbon fluoride materi...

Embodiment 1

[0040] Preparation of modified fluorinated carbon cathode material: Weigh 300 mg of fluorinated mesocarbon microspheres (fluorocarbon molar ratio ~0.86), disperse them in 200 ml of isopropanol, and stir to form a uniform solution. React at 60°C for 10h, after cooling down to room temperature, sonicate for 1.5h, and blow dry at 80°C for 12h.

[0041]Preparation of modified carbon fluoride positive pole piece: Take 12.5mg of polyvinylidene fluoride (PVDF), dissolve it in 1.5ml of N-methylpyrrolidone (NMP), stir to form a uniform solution, and add 100mg of modified carbon fluoride mesophase in turn Carbon microspheres, 12.5 mg of superconducting carbon black conductive agent, prepared modified carbon fluoride positive electrode slurry after stirring for 8 hours, coated on ordinary aluminum foil, and dried at 100 ° C.

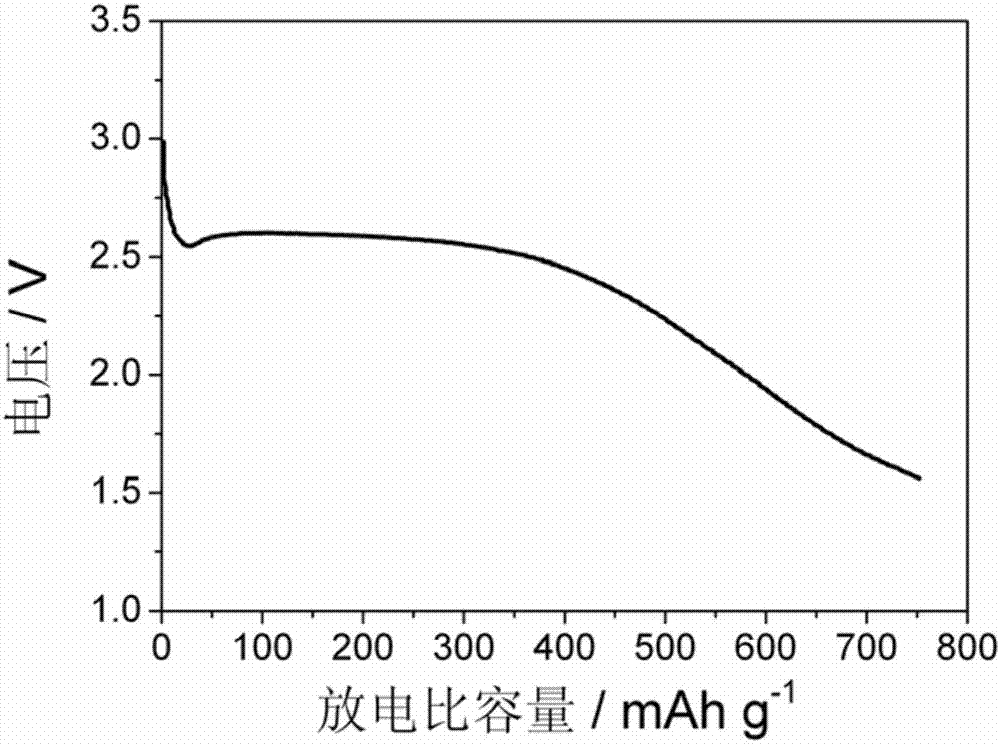

[0042] Preparation of modified carbon fluoride battery: The prepared modified carbon fluoride positive electrode was punched into circular pole pieces of Φ14mm, an...

Embodiment 2

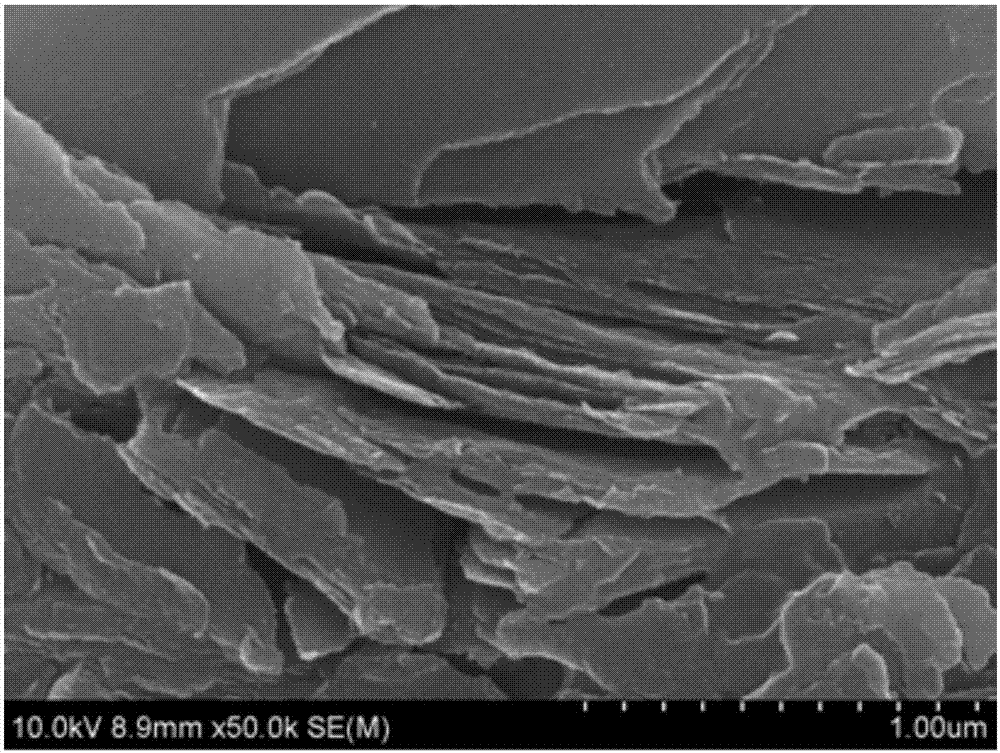

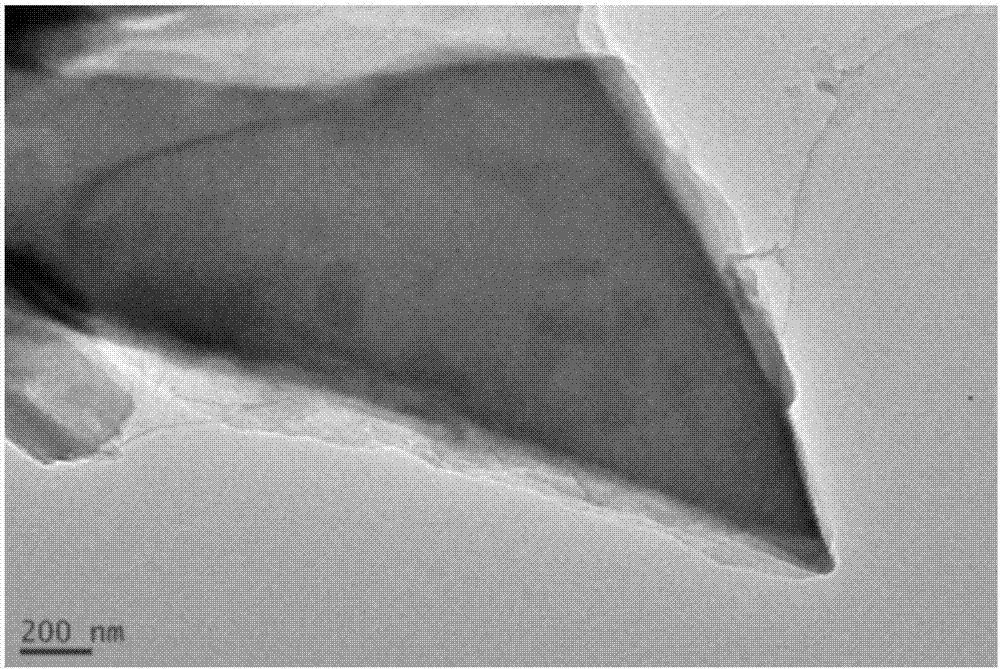

[0044] Preparation of modified carbon fluoride cathode material: Weigh 200 mg of fluorinated graphite (fluorocarbon molar ratio ~0.7), disperse in 400 ml of N-methylpyrrolidone (NMP), and stir to form a uniform solution. React at 90°C for 10h, after cooling down to room temperature, sonicate for 2h, and blow dry at 100°C for 20h. The microscopic morphology of the modified carbon fluoride material is as follows: figure 2 and image 3 shown.

[0045] Preparation of modified carbon fluoride positive pole piece: Take 15mg of polyvinylidene fluoride (PVDF), dissolve it in 2ml of N-methylpyrrolidone (NMP), stir to form a uniform solution, add 105mg of modified fluorinated graphite, 30mg of superconducting The carbon black conductive agent was stirred for 8 hours to prepare a carbon fluoride positive electrode slurry, which was coated on the corroded aluminum foil and dried at 100°C.

[0046] Preparation of unmodified carbon fluoride positive pole piece: take 15mg of polyvinylide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com