Split cell breaker

A crusher and split-type technology, applied in biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as damaged parts, easy tearing at B, and equipment failure, etc., to achieve Simplified structure, reduced production cost and development difficulty, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] Example

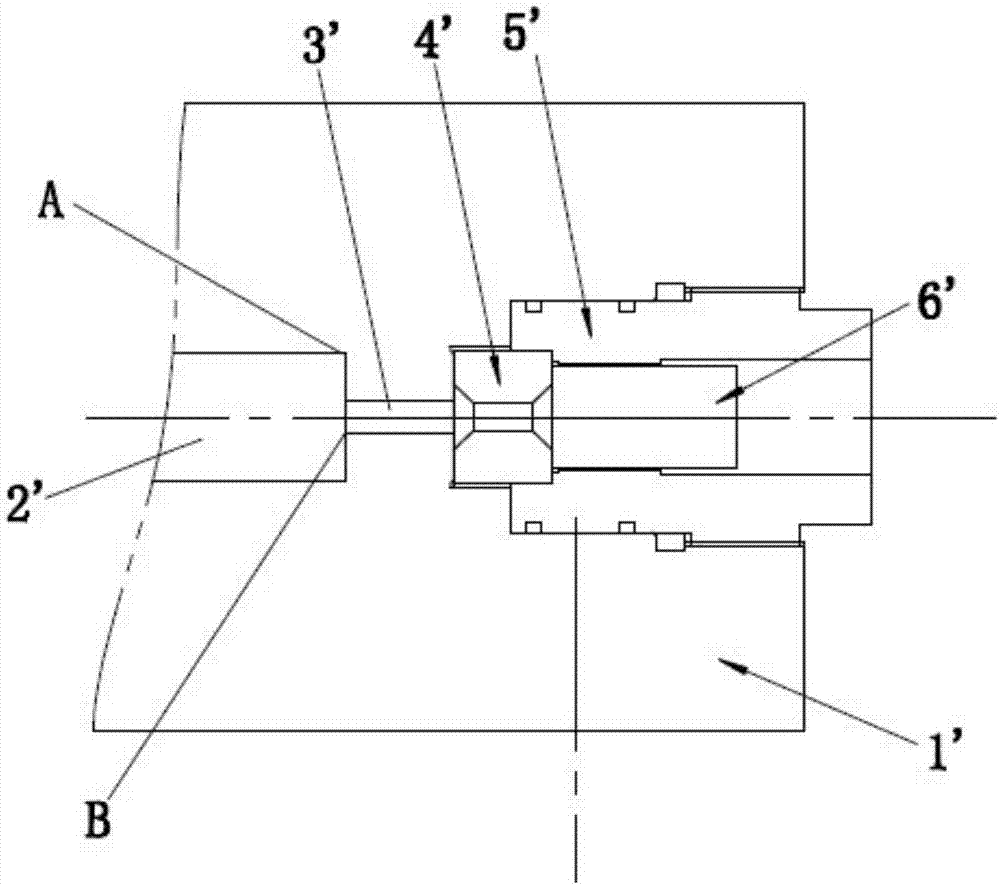

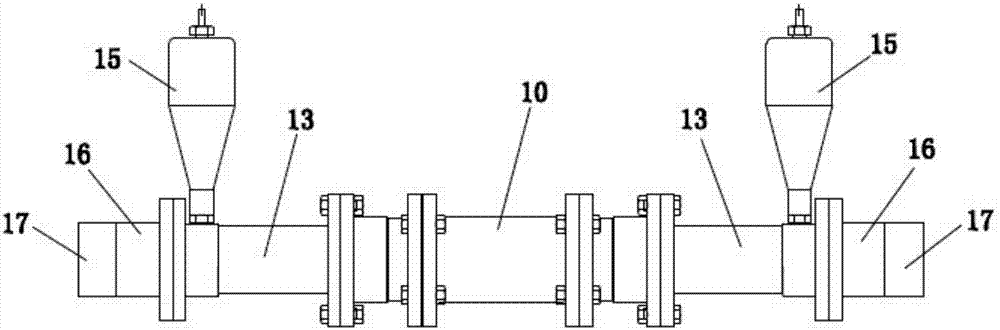

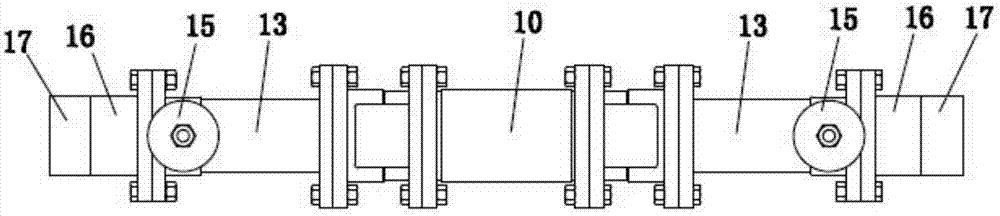

[0030] The specific embodiments of the present invention are as Figure 2 to Figure 5 As shown, a split cell crusher includes a high-pressure cylinder 13 connected with a hopper 15 on one side. One end of the high-pressure cylinder 13 is connected with a piston cylinder 10, and the other end of the high-pressure cylinder 13 is connected with a crusher 16 and a hydraulic cylinder 17 in sequence. The crusher 16 includes a cylinder 1 with a first material passage 2 whose input end is connected to a high-pressure cylinder 13, and a central part connected in sequence along the output end of the first material passage 2 in the cylinder 1 The communicating nest 7, the valve seat 4 and the guide sleeve 5 are communicated with the hydraulic cylinder 17. The guide sleeve 5 is provided with a valve core 6 on one side of the valve seat 4. The hydraulic cylinder 17 provides pressure to one end of the valve core 6 so that the other end of the valve core 6 is pressed against t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap