Inductive heating device for high-pressure oil supply path of crude oil engine

A diesel engine and heating device technology, applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve the problems of destroying the smoothness of intake air, occupying the area of intake passage, and starting at low temperature, so as to solve the problem of cold start, The effect of solving adverse effects and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

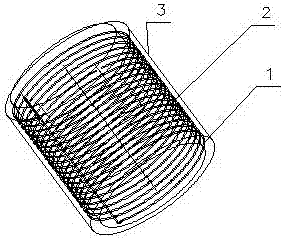

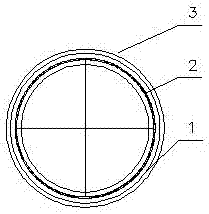

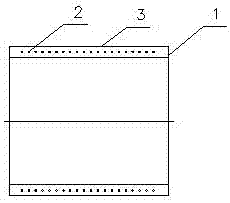

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 As shown, the present invention is further described as follows: an induction type diesel engine high-pressure oil supply oil circuit heating device includes a plurality of induction heating sleeves 4 and a heating controller 5, and the heating controller 5 is provided separately, and the induction heating sleeve 4 includes a protective cover 3, a plastic frame 1, and a spiral induction coil 2. The spiral induction coil 2 is packaged in the plastic frame 1, and the protective cover 3 is set on the plastic frame 1 to form an integrated structure; the diameter of the inner hole of the plastic frame 1 is Compatible with the outer diameter of the oil passage interface (oil inlet oil passage interface; oil outlet oil passage interface;) of the high pressure common rail tank assembly 6 of the diesel engine, the spiral induction coils of multiple induction heating sleeves 4 are connected in series through the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com