Exhaust gas recirculation system

A recirculation system, a technology of the circulation system, applied in the directions of gas treatment, combustion product treatment, combustion method, etc., can solve problems such as environmental pollution, waste of nitric acid resources, ozone layer destruction, etc., achieve good spray effect, reduce emissions, Even spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

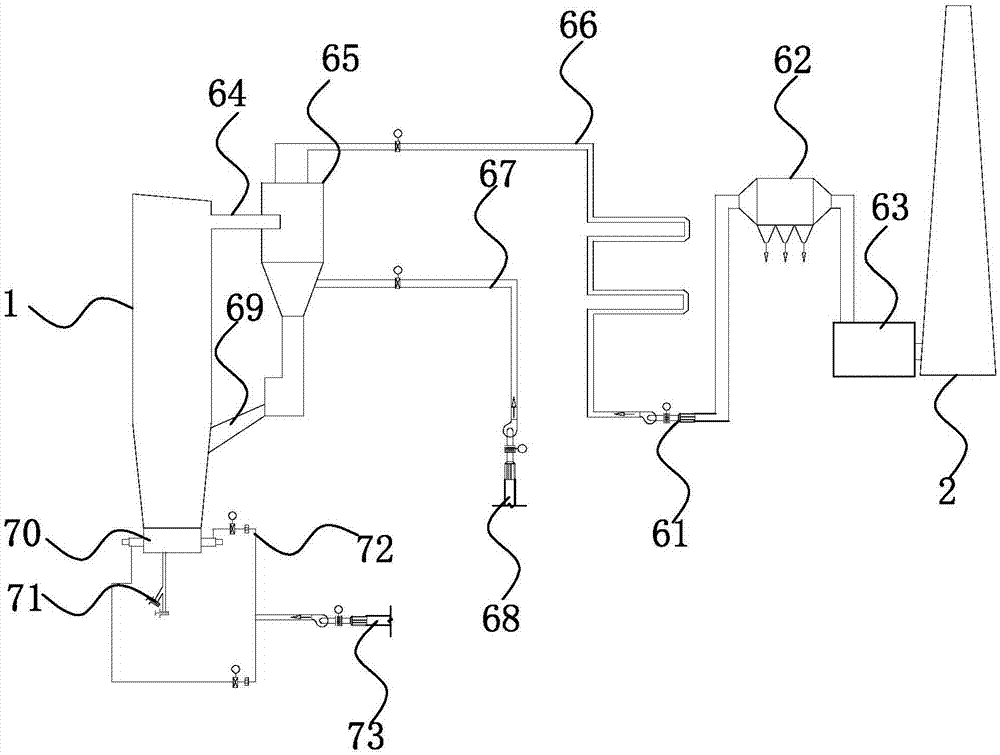

[0038] Example 1: A flue gas recirculation system, such as figure 1 , Including circulating fluidized bed boiler 1, circulating fluidized bed boiler 1 is connected to flue 64, flue 64 is connected to cyclone separator 65, the top of cyclone separator 65 is connected to induced draft fan 61 through curved network pipe 66, and induced draft fan 61 is connected to dust collector 62 The dust collector 62 is connected to the chimney 2 through the desulfurization device 63; the side wall of the cyclone separator 65 is connected to the sweeping fan 68 through a right-angle pipe 67, and the bottom of the cyclone separator 65 is connected to the circulating fluidized bed boiler 1 through an ash pipe connection 69.

[0039] The bottom of the circulating fluidized bed boiler 1 is provided with a cooling cycle system. The cooling cycle system includes a cooling chamber 70 arranged at the bottom of the circulating fluidized bed boiler 1. A circulating pipe 72 is provided on the side wall of the...

Example Embodiment

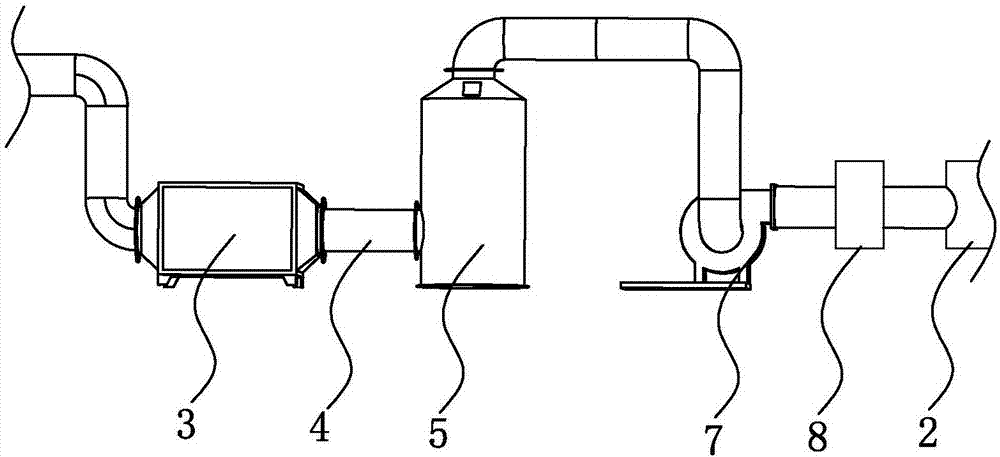

[0048] Embodiment 2: A flue gas recirculation system, such as Figure 5 The difference from the first embodiment is that: a return pipe 15 is provided on the curved network pipe 66, one end of the return pipe 15 is connected to the curved network pipe 66, and the other end is connected to the circulating fluidized bed boiler 1; the flue gas enters the curved network pipe 66 and passes After multiple rotations and cooling, it is returned to the circulating fluidized bed boiler 1 by the return pipe 15 to reduce the production of flue gas nitrogen oxides, thereby effectively improving the production of harmful substances in the flue gas, and then discharge after dust removal treatment, which has little air pollution.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap