Glass fiber belt winding guide and angle adjusting device

An angle adjustment device and an angle adjustment board technology, which can be applied to other household appliances, household appliances, applications, etc., can solve problems such as slow production efficiency, inconvenient disassembly and assembly, and complicated procedures, and achieve slow production efficiency and stable and reliable use , the effect of high winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

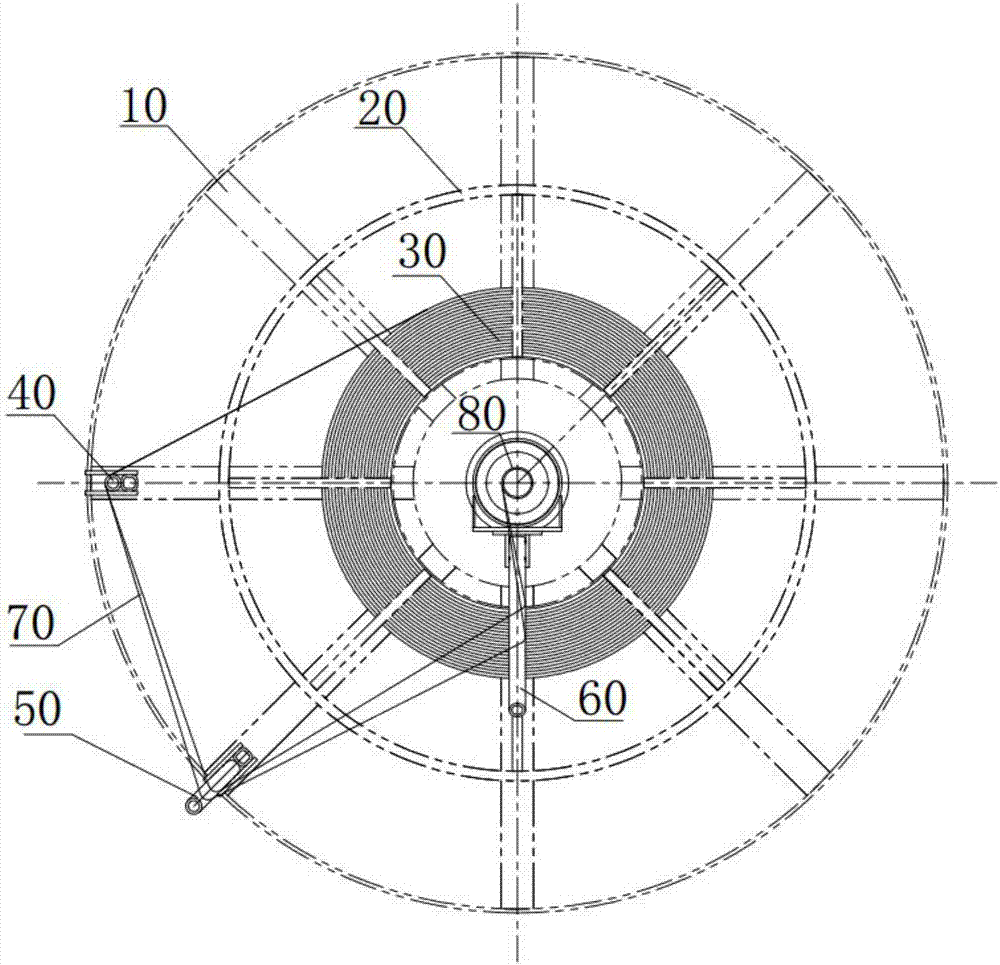

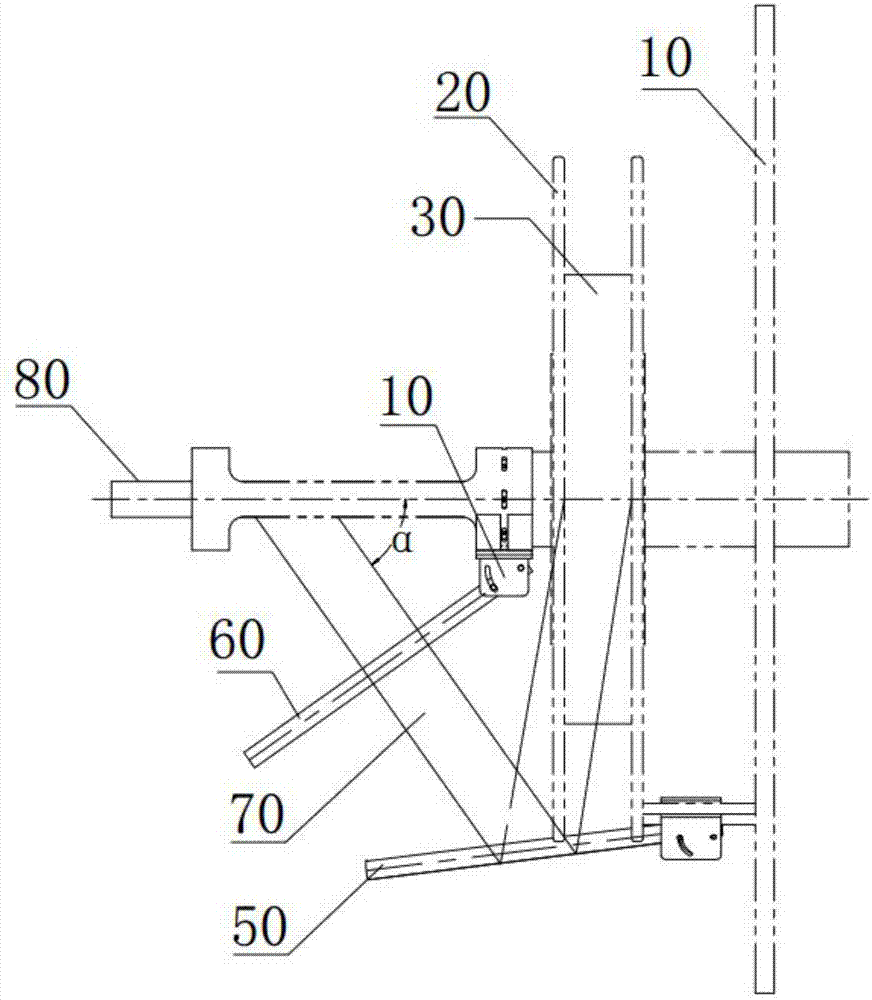

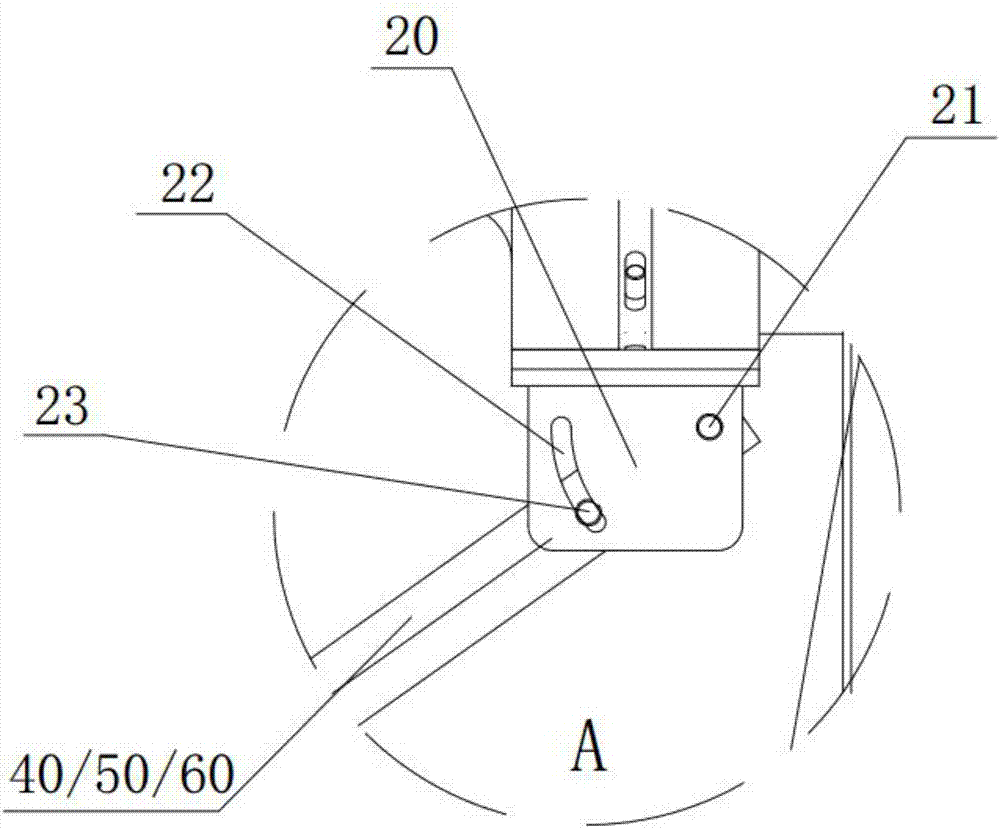

[0024] The invention provides a glass fiber tape winding guide and angle adjustment device, which makes the glass fiber tape to be smoothly and evenly wound on the core tube after the angle is adjusted by several guide rods, and the winding is ensured by the guide rod on the main shaft, the motor and the reducer The tension force at the time, through the flattening and pressing mechanism to ensure that the glass fiber tape is evenly wound on the core tube to form the reinforced layer of the composite tube.

[0025] The present invention will be described in detail and concretely below through specific embodiments, so as to better understand the present invention, but the following embodiments do not limit the scope of the present invention.

[0026] Such as Figure 1-2 As shown, this embodiment provides a glass fiber tape winding guide and angle adjustment device, which includes a driving shaft 30 and a fiberglass tape upper tray 20, and also includes: a glass fiber tape winding gu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap