Preparation method of tantalum 2.5 tungsten alloy plate

A tungsten alloy and sheet technology, applied in the field of preparation of tantalum 2.5 tungsten alloy sheet, can solve the problems of uneven structure of tantalum tungsten alloy sheet, mechanical properties cannot meet actual requirements, increase production cost, etc. The effect of fine particle size and reduction of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

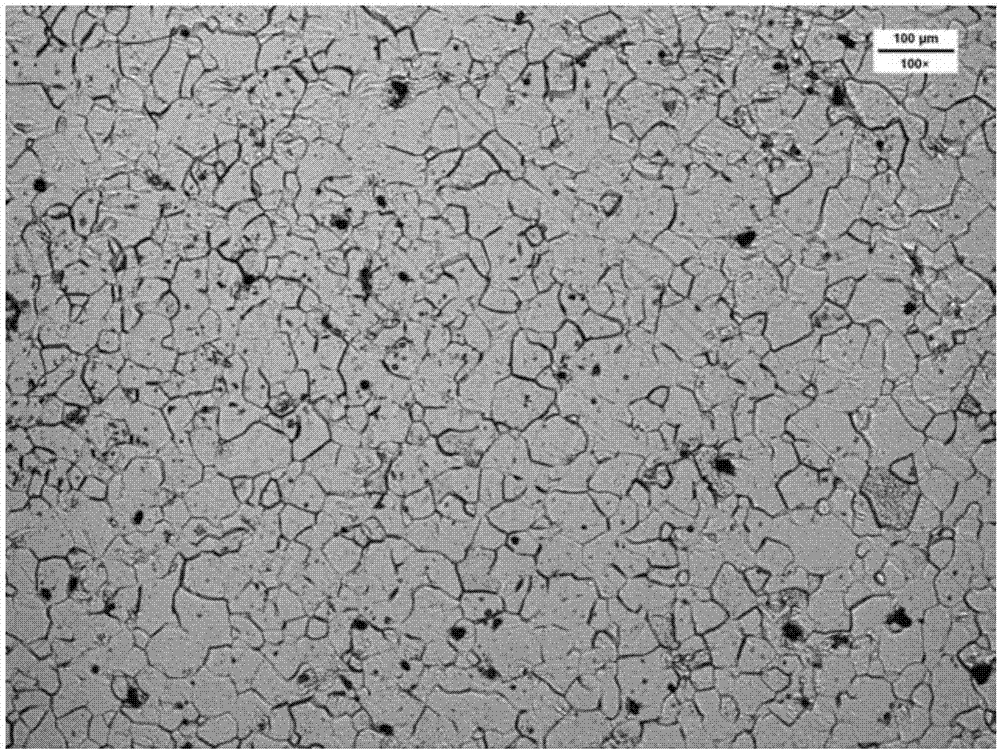

[0029] Example 1

[0030] A kind of preparation method of tantalum 2.5 tungsten alloy plate of the present invention comprises the following steps:

[0031] (1) The tantalum 2.5 tungsten alloy ingot smelted by electron beam twice has a diameter of 130 mm and a length of 150 mm. The composition of each element of the tantalum 2.5 tungsten alloy ingot is shown in Table 1:

[0032] Table 1 Composition of Tantalum 2.5 Tungsten Alloy Ingot

[0033]

[0034] (2) Peel off the tantalum 2.5 tungsten alloy ingot obtained in step (1), remove the surface casting layer, the surface of the tantalum 2.5 tungsten alloy light ingot after lathing is smooth and free of holes, and then carry out phase matching on the tantalum 2.5 tungsten alloy light ingot Controlled array ultrasonic flaw detection to ensure that there are no internal defects in the tantalum 2.5 tungsten alloy ingot;

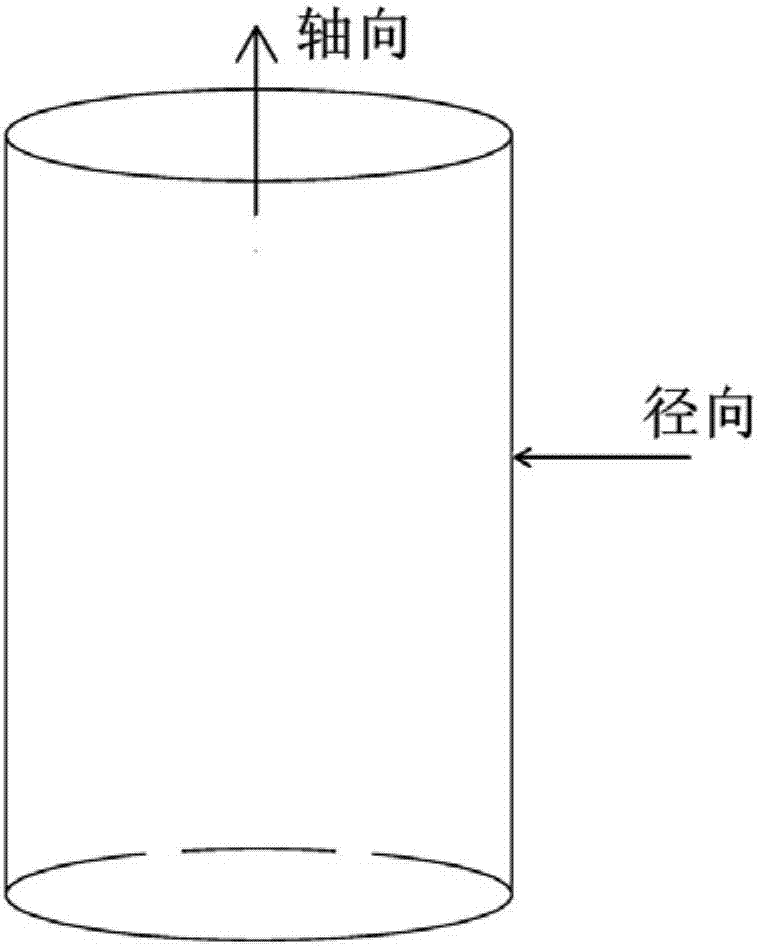

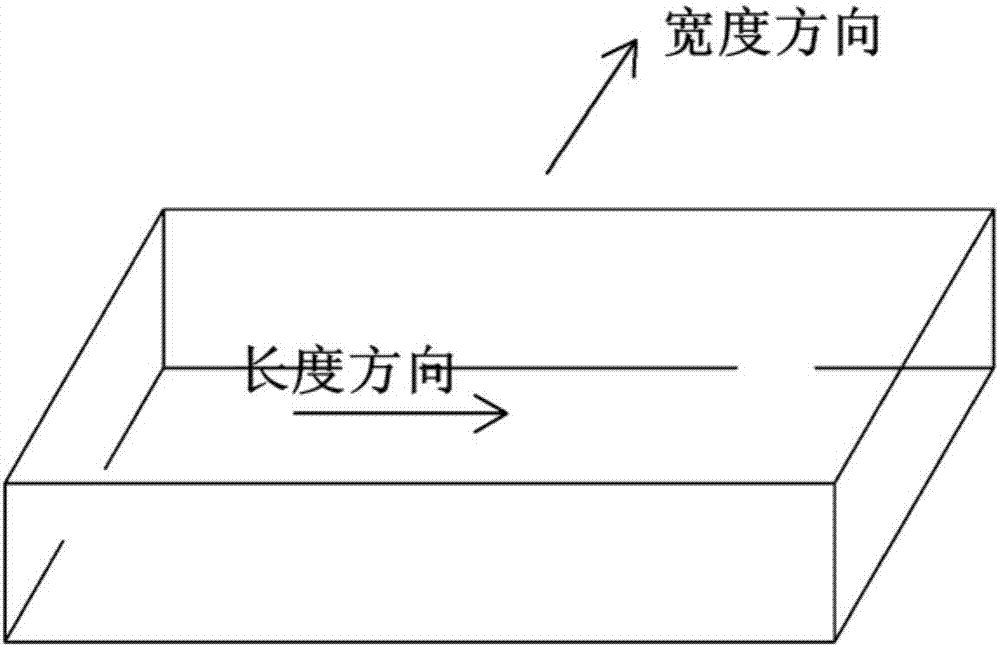

[0035] (3) Cold forging the tantalum 2.5 tungsten alloy light ingot obtained in step (2), the forging equip...

Example Embodiment

[0043] Example 2

[0044] A kind of preparation method of tantalum 2.5 tungsten alloy plate of the present invention comprises the following steps:

[0045] (1) The diameter of the tantalum 2.5 tungsten alloy ingot melted twice by electron beam is 130 mm, and the length is 150 mm. The composition of each element of the tantalum 2.5 tungsten alloy ingot is shown in Table 1;

[0046] (2) Peel off the tantalum 2.5 tungsten alloy ingot obtained in step (1), remove the surface casting layer, the surface of the tantalum 2.5 tungsten alloy light ingot after lathing is smooth and free of holes, and then carry out phase matching on the tantalum 2.5 tungsten alloy light ingot Controlled array ultrasonic flaw detection to ensure that there are no internal defects in the tantalum 2.5 tungsten alloy ingot;

[0047] (3) Cold forging the tantalum 2.5 tungsten alloy light ingot obtained in step (2), the forging equipment used is a screw press, the cold forging process first adopts upsetting,...

Example Embodiment

[0055] Example 3

[0056] A kind of preparation method of tantalum 2.5 tungsten alloy plate of the present invention comprises the following steps:

[0057] (1) The diameter of the tantalum 2.5 tungsten alloy ingot melted twice by electron beam is 130 mm, and the length is 150 mm. The composition of each element of the tantalum 2.5 tungsten alloy ingot is shown in Table 1;

[0058] (2) Peel off the tantalum 2.5 tungsten alloy ingot obtained in step (1), remove the surface casting layer, the surface of the tantalum 2.5 tungsten alloy light ingot after lathing is smooth and free of holes, and then carry out phase matching on the tantalum 2.5 tungsten alloy light ingot Controlled array ultrasonic flaw detection to ensure that there are no internal defects in the tantalum 2.5 tungsten alloy ingot;

[0059] (3) Cold forging the tantalum 2.5 tungsten alloy light ingot obtained in step (2), the forging equipment used is a screw press, the cold forging process first adopts upsetting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap