Production equipment of large-length, large-diameter, high-strength and high-conductivity novel composite wire and process thereof

A composite wire and production equipment technology, which is applied in the production equipment and technology field of new composite wire with large length, large diameter, high strength and high conductivity, can solve the problems of high vacuum production cost, long production cycle, length, weight and shape restrictions, etc. Achieve the effects of strengthening firmness, improving tensile strength and electrical conductivity, and having obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example 1:

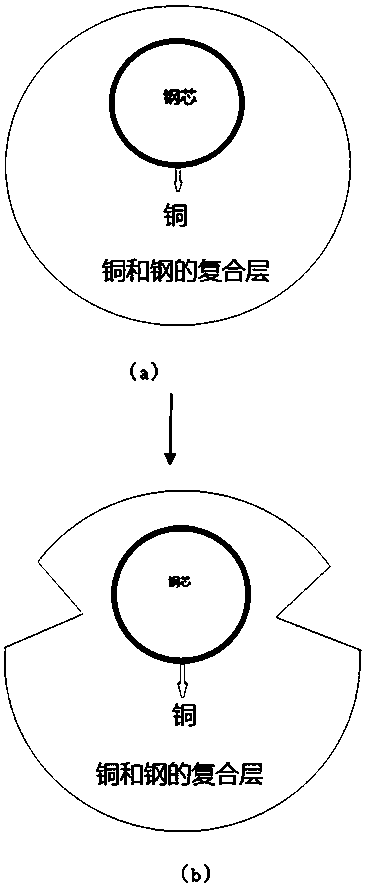

[0040] Prepared as figure 1 (A) The contact line shown without grooves.

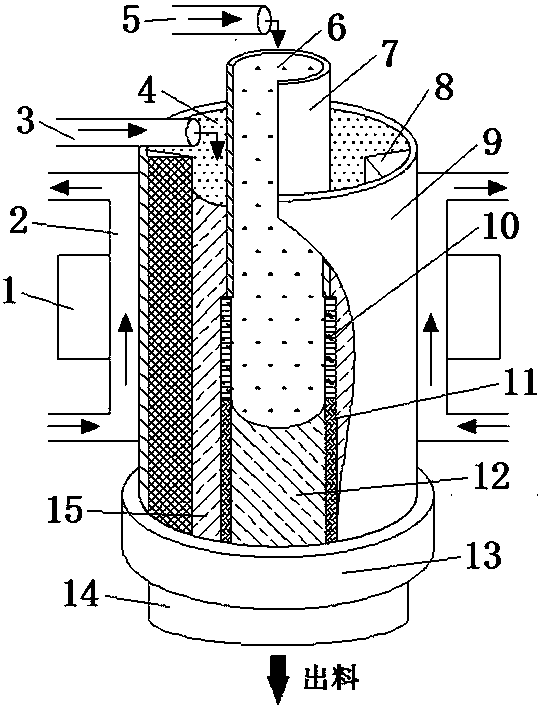

[0041] A production equipment for a new type of large-length, large-diameter, high-strength, high-conductivity composite wire rod, including an internal mold tube 7, an external mold tube 9, a circulating cooling system 2, and a coil 1. The diameter of the external mold tube 9 is larger than that of the internal mold tube 7. The inner mold tube 7 is sleeved into the outer mold tube 9, and the copper liquid 4 is injected between the inner mold tube 7 and the wall of the outer mold tube 9. When the copper liquid 4 passes through the circulating cooling system 2, the upper part is the copper liquid 4, and the lower part Partly solidified into a copper tube 15, the upper inlet of the inner mold tube 7 is higher than the inlet of the outer mold tube 9, and the outlet of the inner mold tube 7 is located in the middle of the solidified copper tube 15. The inner mold tube 7 has the center of the ...

Example Embodiment

[0046] Example 2: Preparation as figure 1 (B) Contact line including groove shown

[0047] A new type of production equipment for large-length, large-diameter, high-strength, high-conductivity composite wire, such as figure 2 As shown, it includes an inner mold tube 7, an outer mold tube 9, a circulating cooling system 2, a coil 1, a contact line groove mold 8, and the distribution of the contact line groove mold 8 is biased toward the center of the inner mold tube 7; , The diameter of the outer mold tube 9 is larger than the inner mold tube 7, the inner mold tube 7 is sleeved into the outer mold tube 9, and the copper liquid 4 is injected between the inner mold tube 7 and the wall of the outer mold tube 9, and the copper liquid 4 is circulated When cooling system 2, the upper part is copper liquid 4, the lower part is solidified into copper tube 15, the upper inlet of the inner mold tube 7 is higher than the inlet of the outer mold tube 9, and the outlet of the inner mold tube ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap