Seed crystal treatment method and silicon carbide crystal growth method

A technology of crystal growth and processing methods, applied in crystal growth, single crystal growth, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

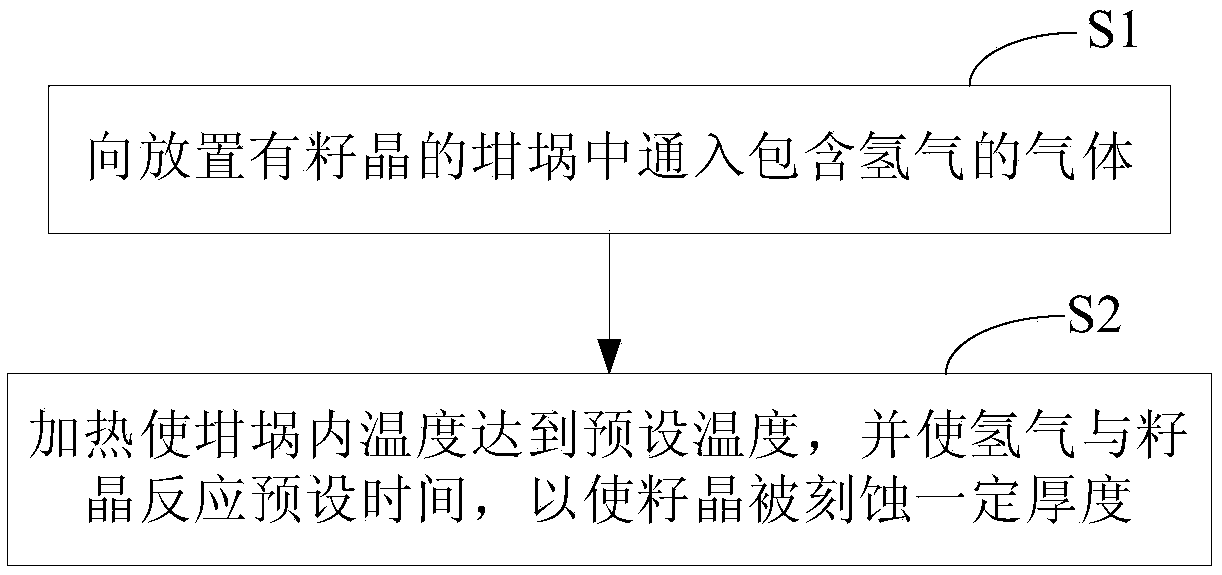

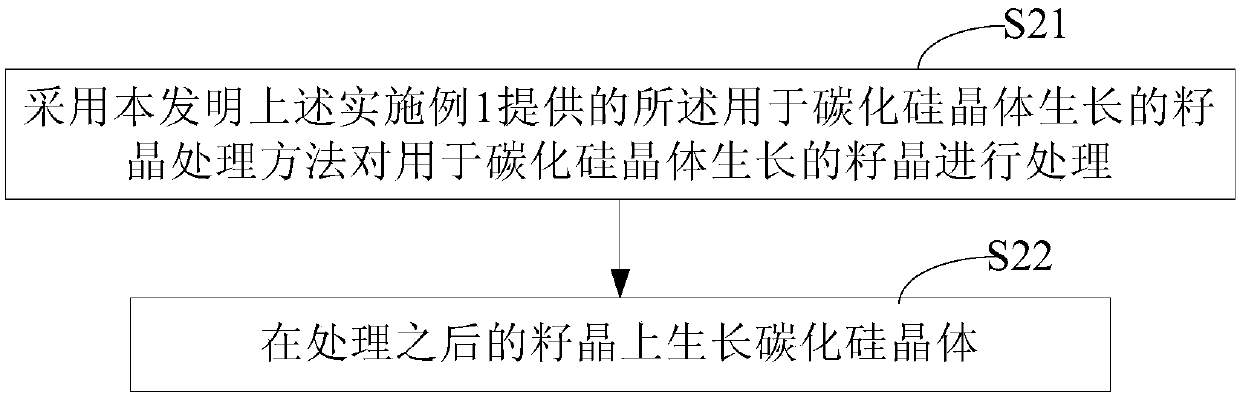

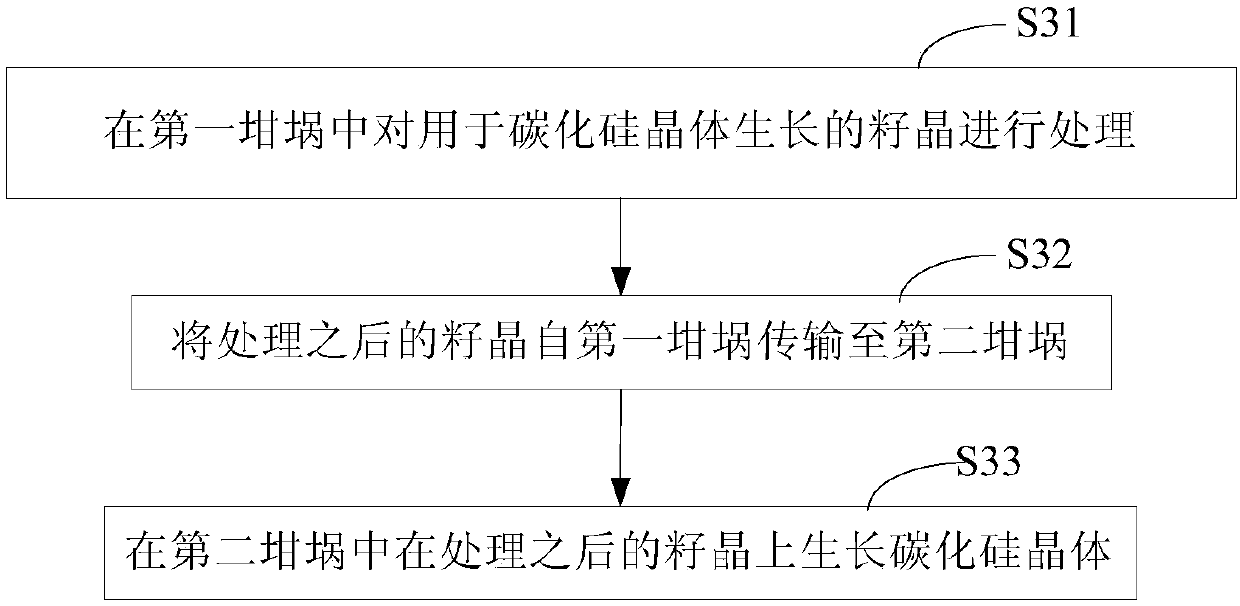

[0036] figure 1 For the working flow diagram of the seed crystal treatment method for silicon carbide crystal growth provided by the embodiment of the present invention, please refer to figure 1 , the seed crystal treatment method for silicon carbide crystal growth provided by the embodiment of the present invention includes the following steps:

[0037] S1, passing a gas containing hydrogen into the crucible on which the seed crystal is placed.

[0038] Specifically, in practical applications, the crucible is generally placed in a crystal growth furnace, and the crucible is generally made of graphite material, and the graphite material has gas permeability, which makes the crystal growth furnace and the crucible actually in a gas communication state. Therefore, In step S1, the gas may be directly fed into the crystal growth furnace, and the gas may pass through the graphite material and enter the crucible.

[0039] S2, heating to make the temperature inside the crucible rea...

example 1

[0053] Example 1, a silicon carbide seed crystal was fixed on the top of a crucible, and the crucible was placed in a crystal growth furnace. Control the pressure in the crystal growth furnace to be maintained at 10000 Pa, and the temperature rises to 1500 ° C, directly feed a mixed gas of 20% (hydrogen content) hydrogen and argon into the crystal furnace, etch the seed crystal for 2 hours (hours), and finally, The growth surface of the seed crystal can remove surface pollution, scratches and some defects.

example 2

[0054]Example 2, the silicon carbide seed crystal was fixed on the top of the crucible, and the crucible was placed in the crystal growth furnace. Control the pressure in the crystal growth furnace to keep at 1000 Pa, raise the temperature to 1600°C, directly feed the gas containing only hydrogen into the crucible, etch the seed crystal for 1 hour (hour), and finally, the growth surface of the seed crystal can remove surface pollution, Scratches and partial defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com