Catalytic purification treatment method of voc-containing exhaust gas

A technology for catalytic purification and treatment methods, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of large investment and poor safety, and achieve the effect of reducing investment, high safety and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

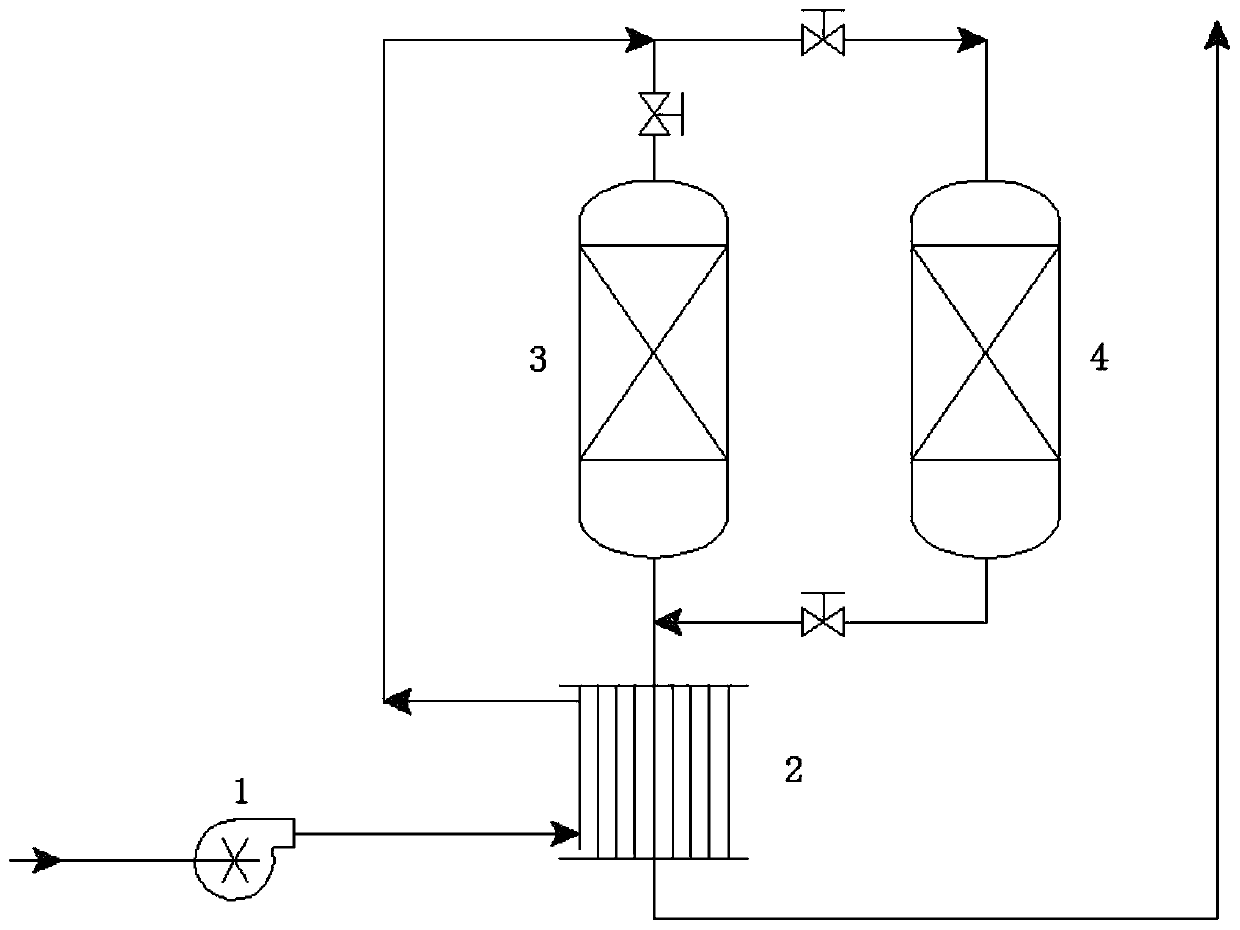

[0022] A kind of catalytic purification device for VOC treatment, its process is shown in figure 1 , during device start-up, 50m 3 / h of VOCs exhaust gas, in which the concentration of formaldehyde is 3500mg / m 3 , the concentration of other VOCs components is 1200mg / m 3 , the temperature is 60°C, and the pressure is normal pressure. The fan boosts the pressure (1) to 5kpa and enters the heat exchanger (2). The heat exchanger is a shell-and-tube heat exchanger with a size of DN50*1200 and a heat transfer area of 1.6m 2 , because the whole device is a cold standby during the start-up process, the exhaust gas exits the heat exchanger without temperature rise, and the exhaust gas enters the low-temperature catalytic oxidation reactor (4), and the reactor is filled with a low-temperature formaldehyde catalyst, which is CeO supported on nano-alloy particles 2 Carrier, containing Ru, Rh, Pt, Pd precious metals, in terms of mass fraction, the content of Ru is 0.25%, the content of...

Embodiment 2

[0026] A kind of catalytic purification device for VOC treatment, its process is shown in figure 1 , during device start-up, 50m 3 / h of VOCs exhaust gas, in which the concentration of formaldehyde is 3000mg / m 3 , the concentration of other VOCs components is 80mg / m 3 , the temperature is 30°C, the pressure is 100kpaA, the fan boosts the pressure (1) to 5kpa and enters the heat exchanger (2), the heat exchanger is a shell-and-tube heat exchanger, the size is DN50*1200, and the heat exchange area is 1.6m 2 , because the whole device is cold standby during the start-up process, the exhaust gas exits the heat exchanger without temperature rise, and the exhaust gas enters the low-temperature catalytic oxidation reactor (4), and the reactor is filled with a low-temperature catalyst, which is CeO supported on nano-alloy particles 2 Carrier, containing Ru, Rh, Pt, Pd precious metals, in terms of mass fraction, the content of Ru is 0.25%, the content of Rh is 0.5%, the content of Pt...

Embodiment 3

[0030] A kind of catalytic purification device for VOC treatment, its process is shown in figure 1 , during device start-up, 50m 3 / h of VOCs exhaust gas, in which the concentration of formaldehyde is 6000mg / m 3 , the concentration of other VOCs components is 80mg / m 3 , the temperature is 30°C, the pressure is 100kpaA, the fan boosts the pressure (1) to 5kpa and enters the heat exchanger (2). The heat exchanger is a shell-and-tube heat exchanger with a size of DN50*1200mm and a heat transfer area of 1.6m 2 , because the whole device is cold standby during the start-up process, the exhaust gas exits the heat exchanger without temperature rise, and the exhaust gas enters the low-temperature catalytic oxidation reactor (4), and the reactor is filled with a low-temperature catalyst, which is CeO supported on nano-alloy particles 2 Carrier, containing Ru, Rh, Pt, Pd precious metals, in terms of mass fraction, the content of Ru is 0.25%, the content of Rh is 0.5%, the content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com