A method for separating magnetic impurities in ultrafine cobalt compound powder

A technology for magnetic impurities and compounds, applied in the field of battery-grade cobalt material preparation, can solve the problems of poor separation of magnetic impurities, increased difficulty in demagnetization, poor stability, etc., and achieves improved demagnetization efficiency, high price, and satisfactory magnetic The effect of impurity index requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 840kg (dry basis physical weight) of cobalt hydroxide wet filter cake into the slurrying tank, add pure water 0.42m 3 Add 3.0 kg of ammonium salt to pure water, start stirring, and slurry at 35° C. for 1.0 h to obtain a cobalt hydroxide slurry with a solid content of 67%.

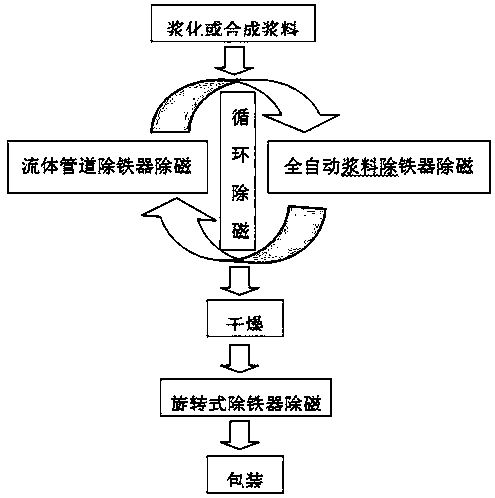

[0026] Pump the obtained cobalt hydroxide slurry into the demagnetization raw material tank, turn on the automatic slurry iron remover and the centrifugal pump at the outlet of the raw material tank successively, and the slurry is pumped through the fluid pipeline iron remover and the automatic slurry iron remover successively. The slurry is circulated to remove magnetic impurities. Operating conditions for slurry removal of magnetic impurities: magnetic field strength of magnetic medium for fluid pipeline iron remover: 9000GS, magnetic field strength of magnetic medium for fully automatic slurry iron remover: 7500GS, cleaning times of magnetic medium for fluid pipeline iron remover: 3 times (cle...

Embodiment 2

[0031] Put 1000kg (dry basis physical weight) of tricobalt tetroxide into the slurry tank, add 0.60m of pure water 3 pure water, start stirring, and slurry at 25°C for 0.5h to obtain a cobalt tetroxide slurry with a solid content of 62.5%.

[0032] Pump the obtained cobalt tetroxide slurry into the demagnetization raw material tank, turn on the automatic slurry iron remover and the centrifugal pump at the outlet of the raw material tank successively, and the slurry passes through the fluid pipeline iron remover and the automatic slurry iron remover successively under pumping Cycle to remove magnetic impurities. Operating conditions for slurry removal of magnetic impurities: magnetic field strength of magnetic medium for fluid pipeline iron remover: 9500GS, magnetic field strength of magnetic medium for fully automatic slurry iron remover: 8000GS, cleaning times of magnetic medium for fluid pipeline iron remover: 3 times (cleaning 1 time per 0.5h operation times), fully automa...

Embodiment 3

[0038] Using cobalt liquid and ammonium bicarbonate solution as raw materials, a cobalt carbonate slurry with a solid content of 8.8% was synthesized in a synthesis kettle under certain conditions.

[0039] The obtained cobalt carbonate slurry is pumped into the demagnetization raw material tank, and the automatic slurry iron remover and the centrifugal pump at the outlet of the raw material tank are turned on successively. Material circulation to remove magnetic impurities. Operating conditions for slurry removal of magnetic impurities: magnetic field strength of magnetic medium for fluid pipeline iron remover: 10000GS, magnetic field strength of magnetic medium for fully automatic slurry iron remover: 7800GS, cleaning times of magnetic medium for fluid pipeline iron remover: 4 times (cleaning 1 time per 0.5h operation times), fully automatic slurry remover magnetic medium backwash times: 8 times (cleaning once every 15 minutes of operation), slurry cycle demagnetization time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com