Membrane process printing wastewater treatment system and membrane process printing wastewater treatment method

A technology for printing wastewater and treatment system, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of less sludge production and improved denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

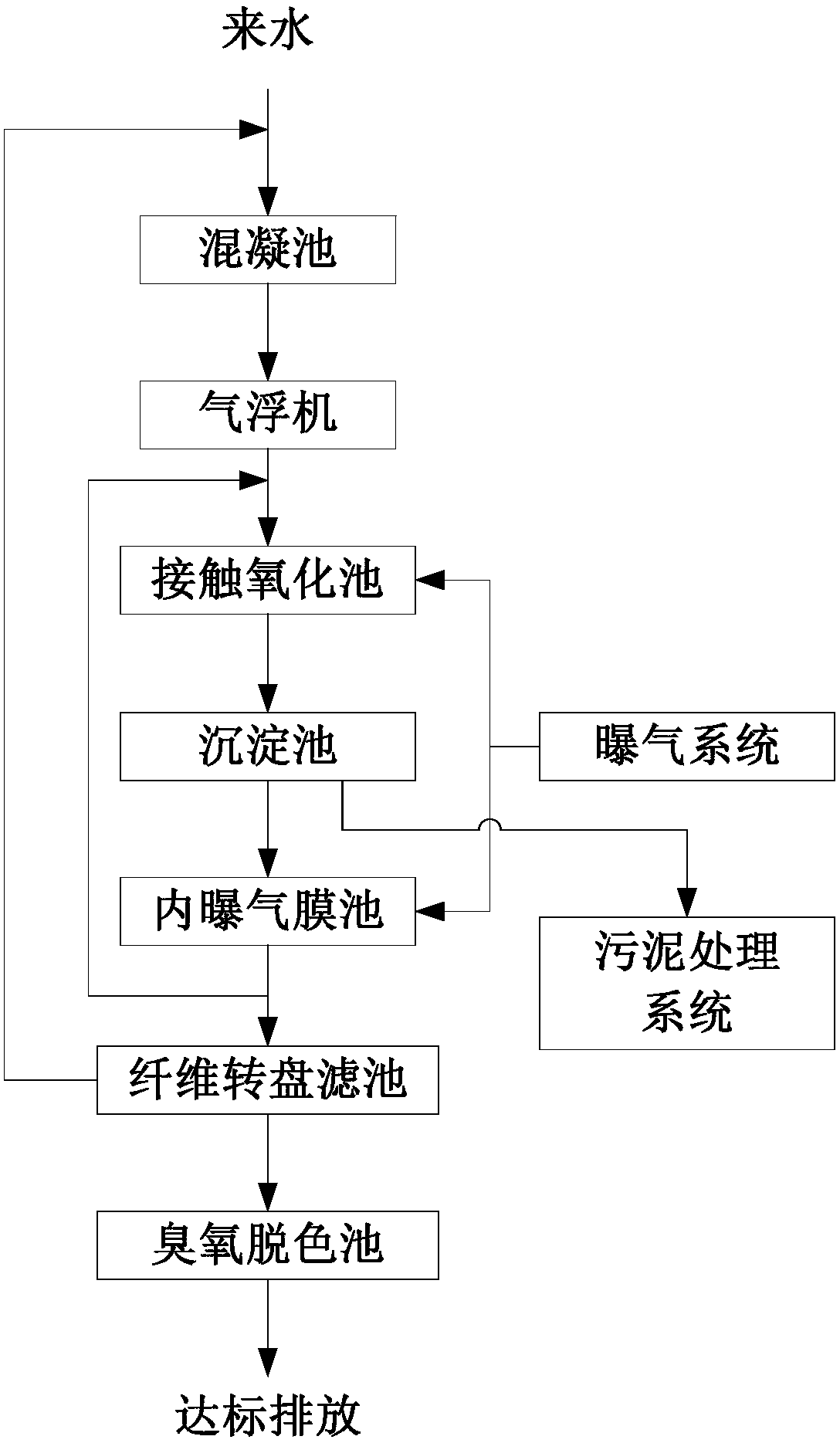

[0064] attached figure 1 It is a schematic diagram of the membrane printing wastewater treatment system. Membrane printing wastewater treatment system includes coagulation tank, air flotation machine, contact oxidation tank, sedimentation tank, inner aeration membrane tank, fiber rotary disc filter tank and ozone decolorization tank connected in sequence. The aeration system is respectively connected with the contact oxidation tank and the inner aeration membrane tank. The inner aeration membrane tank is connected with the contact oxidation tank. The solid packing is suspended in the contact oxidation tank. Hollow fiber membranes are suspended in the inner aeration membrane tank. The fiber rotary disc filter is connected with the coagulation tank. The sedimentation tank is connected with the sludge treatment system.

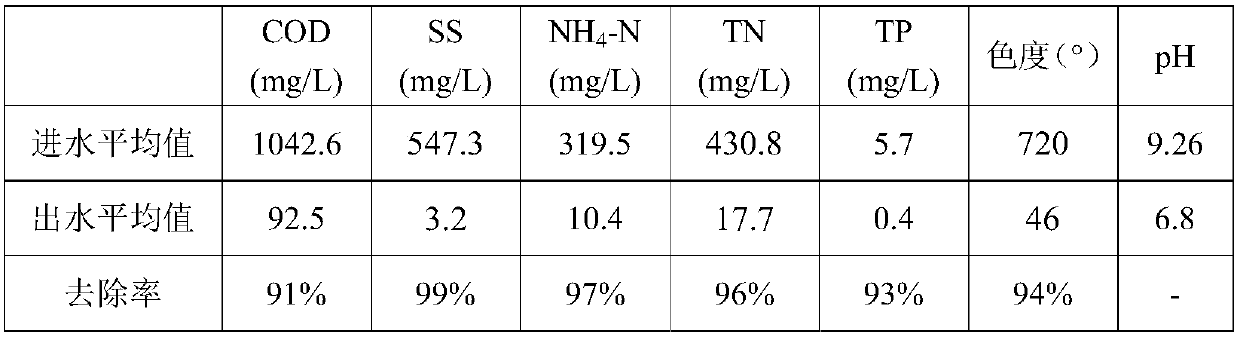

[0065] Attached below figure 1 , and taking the wastewater treatment of a certain printing enterprise in Shantou as an example, the specific process of usi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap