System and method for continuously producing dihydric alcohol ether

A technology of glycol ethers and alcohols, which is applied in the system field of continuous production of glycol ethers, can solve the complex separation process of light components, low selectivity and yield of alcohol ethers, and many by-products of polyethers in reaction time. The problem is to avoid the delight process, reduce the reaction feed alcohol ratio, and avoid the increase of by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

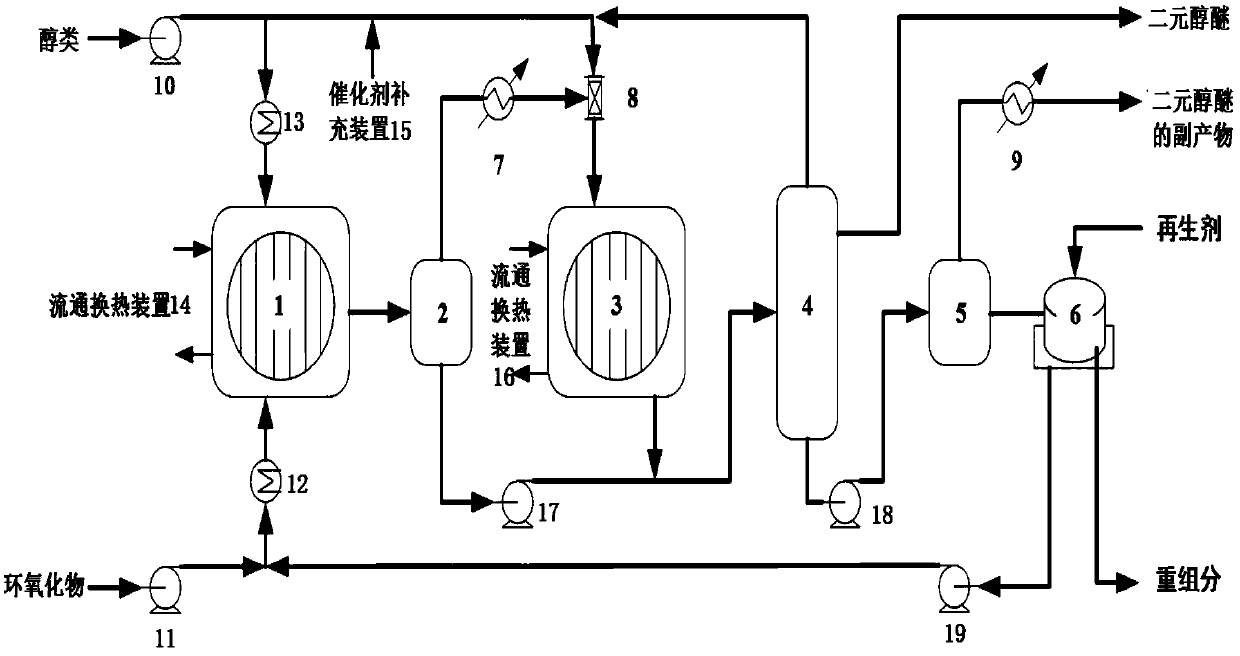

[0105] A system for the production of glycol ethers such as figure 1 As shown, including 1-first-stage microchannel reactor, 2-delight tank, 3-second-stage microchannel reactor, 4-rectification tower, 5-deheavy tank, 6-catalyst regenerator, 7- The top discharge condenser of the light removal tank, 8-static mixer, 9-the top discharge condenser of the heavy removal tank, 10, 11, 17, 18 and 19 are transfer pumps, 12-heat exchange device, 13-heat exchange Device, 14-circulation heat exchange device, 15-catalyst replenishment device, 16-circulation heat exchange device.

[0106] The discharge port of the first-stage microchannel reactor 1 is connected with the feedport of the light removal tank 2, and a circulation heat exchange device 14 is arranged on the first-stage microchannel reactor 1; the upper pipeline of the first-stage microchannel reactor 1 A heat exchange device 13 is provided, and the lower pipeline of the first-stage microchannel reactor 1 is provided with a heat ex...

Embodiment 2

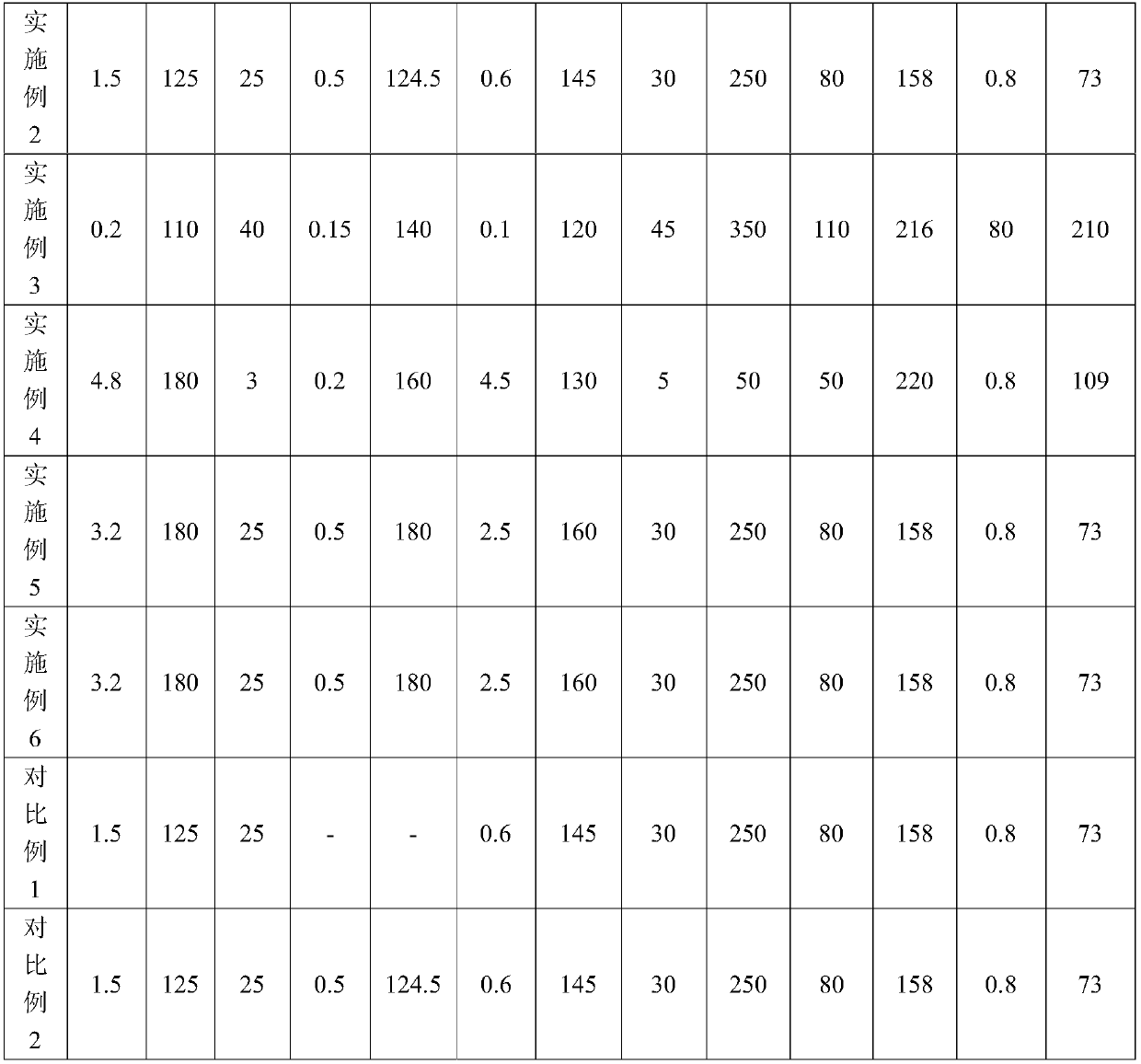

[0113] The present embodiment utilizes the system that embodiment 1 provides to produce propylene glycol methyl ether, specifically comprises the following steps:

[0114] (1) Feed respectively through preheated raw material methanol, propylene oxide and sodium methylate catalyst in the first-stage microchannel reactor 1, methyl alcohol and propylene oxide react rapidly in the reactor to generate propylene glycol methyl ether, the reaction product and unreacted raw materials enter the delightening tank 2 for separation, and the propylene oxide extracted from the top of the delightening tank respectively passes through the condenser 7 to cool down, and the static mixer 8 mixes evenly with the methanol raw material after supplementing the catalyst, and then enters the second stage Microchannel reactor 3 continues to react; The reaction temperature of first-stage microchannel reactor 1 is controlled by hot water;

[0115] Wherein, the propylene oxide feed rate is 10kmol / h, the me...

Embodiment 3

[0129] The present embodiment utilizes the system that embodiment 1 provides to produce ethylene glycol monoethyl ether, specifically comprises the following steps:

[0130] (1) Feed respectively through preheated raw material ethanol, ethylene oxide and sodium ethylate catalyst in the first-stage microchannel reactor 1, and ethanol and oxirane react rapidly in the reactor to generate ethylene glycol ether , the reaction product and unreacted raw materials enter into the delightening tank 2 for separation, and the propylene oxide extracted from the top of the delightening tank respectively passes through the condenser 7 to cool down, and the static mixer 8 mixes evenly with the ethanol raw material after supplementing the catalyst, and then enters the The second stage microchannel reactor 3 continues to react; the reaction temperature of the first stage microchannel reactor 1 is controlled by hot water;

[0131] Wherein, the ethylene oxide feed rate is 10kmol / h, and the ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com