A kind of quality detection method of Hanchuan Zupa preparation

A quality testing method and testing method technology, applied in the field of medical testing, can solve the problems of large Rf value, can not fully reflect the internal quality of Hanchuan Zupa preparation, the determination of main components and active components, and achieve a stable baseline and avoid near-term problems. The effect of greater absorption of UV impurity peaks, reducing the possibility of quality compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

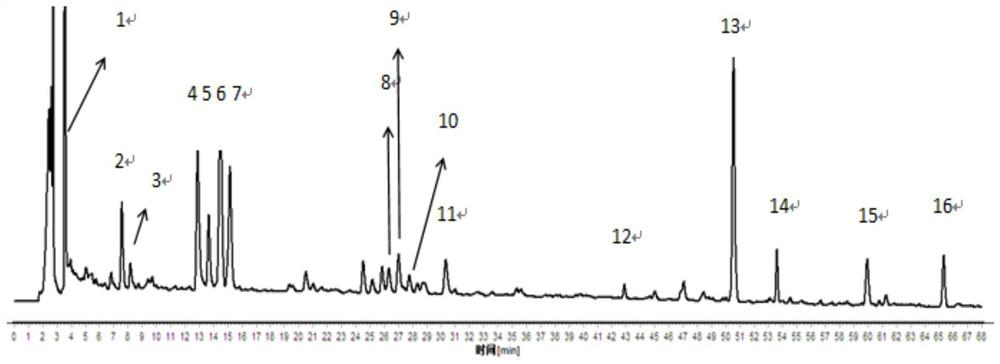

Image

Examples

Embodiment 1

[0049](1) Preparation of the test solution:

[0050] After completely dissolving 0.2g of Hanchuan Zupa granules in 5ml of methanol solution with a mass fraction of 30%, ultrasonically extract for 25min, then filter with a 0.22μm microporous membrane, and the filtrate is the test solution;

[0051] (2) Preparation of reference substance solution:

[0052] After dissolving 1 mg of ammonium glycyrrhizinate in 20 ml of methanol, filter through a 0.22 μm microporous membrane to obtain the reference substance solution;

[0053] (3) Detection:

[0054] Take 10 μl each of the reference solution and the test solution, inject them into a high-performance liquid chromatograph, and record the chromatogram within 68 minutes; wherein, the filler is octadecylsilane bonded silica gel; the mobile phase A is a mass fraction of 0.09 % phosphoric acid solution, the mobile phase B is acetonitrile, the gradient elution method is adopted, the elution flow rate is 1.0ml / min, the volume fraction of ...

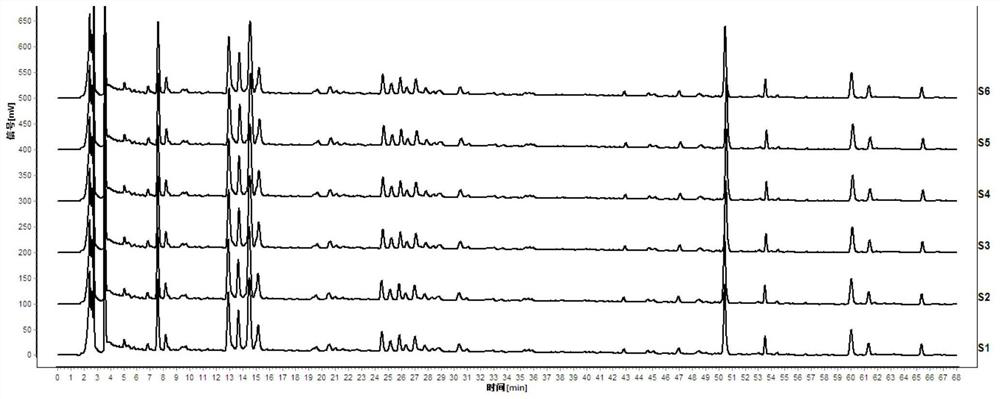

Embodiment 2

[0057] (1) Preparation of the test solution:

[0058] After completely dissolving 0.5g of Hanchuan Zupa granules in 5ml of methanol solution with a mass fraction of 70%, ultrasonically extract for 35min, and then filter with a 0.22μm microporous membrane to obtain the test solution;

[0059] (2) Preparation of reference substance solution:

[0060] After dissolving 2 mg of ammonium glycyrrhizinate in 1 ml of methanol, filter through a 0.22 μm microporous membrane to obtain the reference substance solution;

[0061] (3) Detection:

[0062] Take 5 μl each of the reference substance solution and the test solution, inject them into a high-performance liquid chromatograph, and record the chromatogram within 70 minutes; wherein, the filler is octadecylsilane bonded silica gel; the mobile phase A is a mass fraction of 0.11 % phosphoric acid solution, the mobile phase B is acetonitrile, the gradient elution method is adopted, the elution flow rate is 1.0ml / min, the volume fraction o...

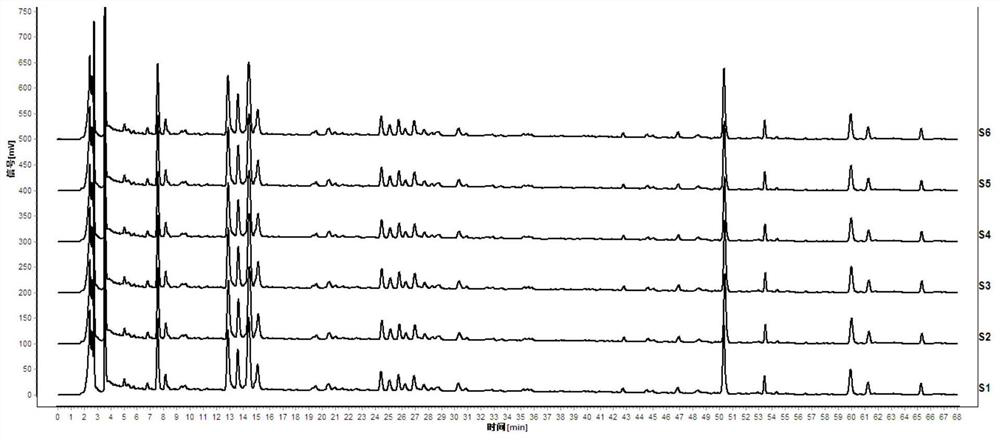

Embodiment 3

[0065] (1) Preparation of the test solution:

[0066] After completely dissolving 0.3g of Hanchuan Zupa granules in 5ml of methanol solution with a mass fraction of 50%, ultrasonically extract for 30min, and then filter with a 0.22μm microporous membrane to obtain the test solution;

[0067] (2) Preparation of reference substance solution:

[0068] After dissolving 2 mg of ammonium glycyrrhizinate in 25 ml of methanol, filter through a 0.22 μm microporous membrane to obtain the reference substance solution;

[0069] (3) Detection:

[0070] Take 8 μl each of the reference substance solution and the test solution, inject them into a high-performance liquid chromatograph, and record the chromatogram within 68 minutes; wherein, the filler is octadecylsilane bonded silica gel; the mobile phase A is a mass fraction of 0.10 % phosphoric acid solution, the mobile phase B is acetonitrile, the gradient elution method is adopted, the elution flow rate is 1.0ml / min, the volume fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com