Compound of quick-setting rapid-hardening cement material and preparation method thereof

A quick-hardening cement and quick-setting technology, which is applied in the field of preparation of quick-setting quick-hardening cement materials, can solve the problems of late strength shrinkage, high production cost and high transportation cost, and achieves improved comprehensive performance, strong practicability and broad prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

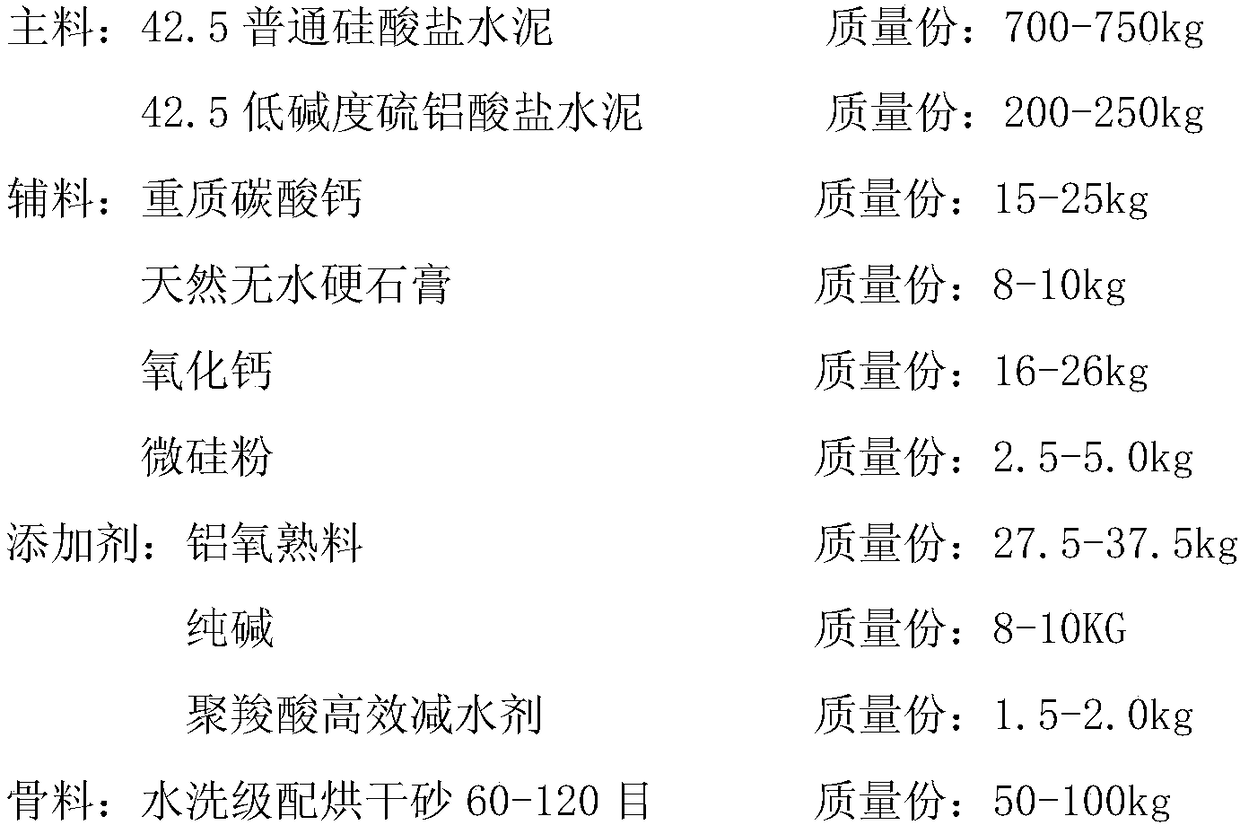

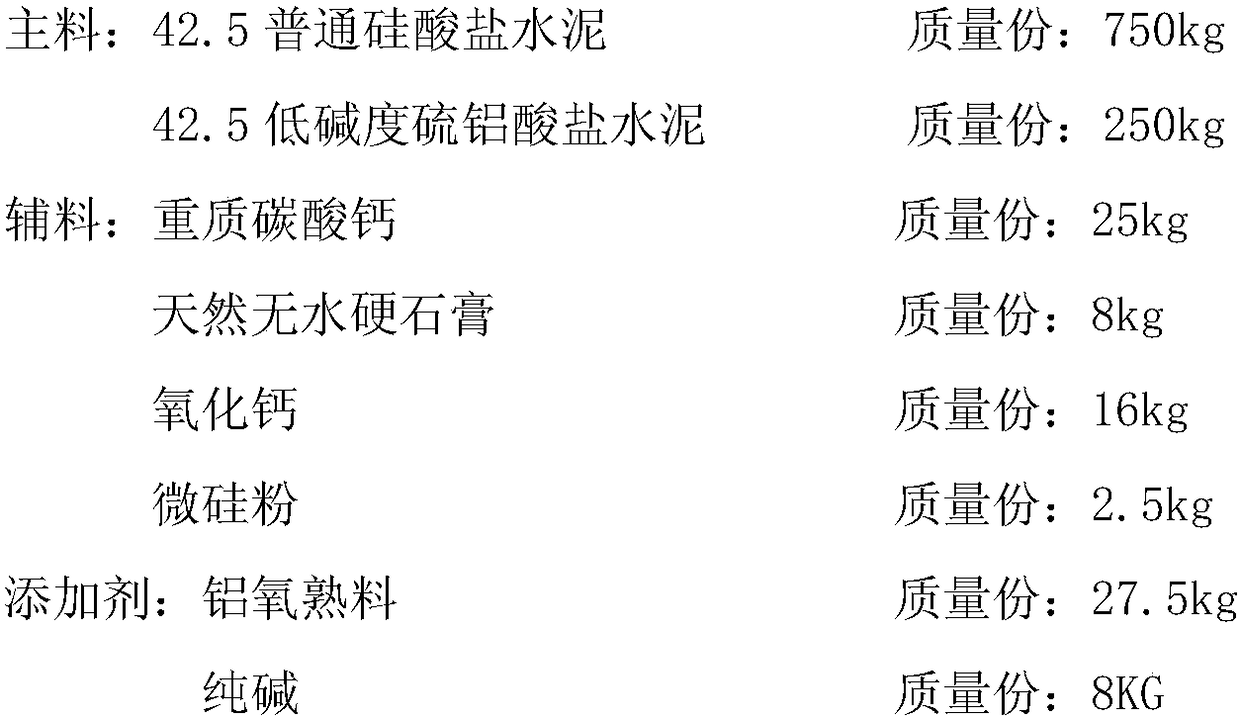

[0023] A compound of quick-setting and fast-hardening cement material, which is mixed and compounded according to the following mass ratios:

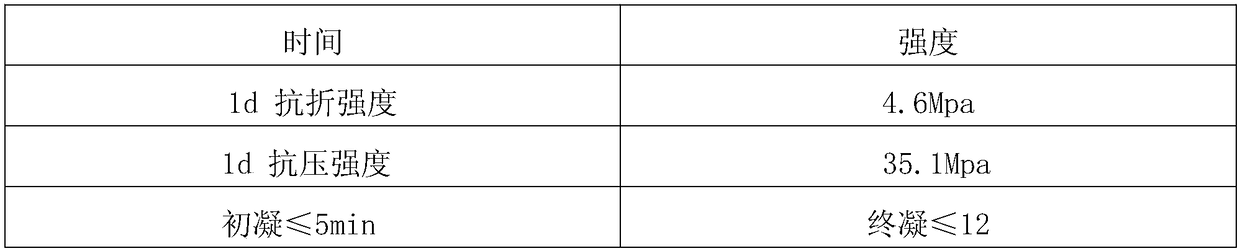

[0024]

[0025]

[0026] The 42.5 ordinary Portland cement in the present invention is fly ash-based Portland cement. The natural anhydrous anhydrite has a Mohs hardness of 3-3.5, a sulfur content of 42-43%, and a specific gravity of 2.98. The calcium content of the calcium oxide is ≥90%, the silicon dioxide content of the micro-silica powder is ≥80%, the alumina clinker is high alumina alumina clinker, and the soda ash is industrial grade sodium carbonate. The mesh number of the washing-graded drying sand screen is 80-100 mesh.

[0027]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com