A kind of method for preparing iron-selenium superconductor

A technology of superconductor and iron selenium, applied in the direction of binary selenium/tellurium compound, metal selenide/telluride, nanotechnology, etc., to achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix selenium powder (1mmol), polyvinylpyrrolidone (60mg), sodium hydroxide (11mmol) and ethylene glycol (10ml), seal the reaction kettle and heat it to 433K, and keep it warm for 3 hours to obtain a selenium-ethylene glycol solution . Ferrous sulfate (0.75mmol) and ethylene glycol (10ml) were mixed and ultrasonically dissolved to obtain an iron-ethylene glycol solution. Mix the selenium-containing ethylene glycol solution and the iron-containing ethylene glycol solution, seal them in a 50ml solvothermal reaction kettle under a nitrogen atmosphere, heat the reaction kettle to 493K, and keep it warm for 24 hours to obtain β-FeSe nanosheets. The β-FeSe nanosheets were centrifuged and washed 3 times with absolute ethanol, dried in vacuo, and stored in vacuo.

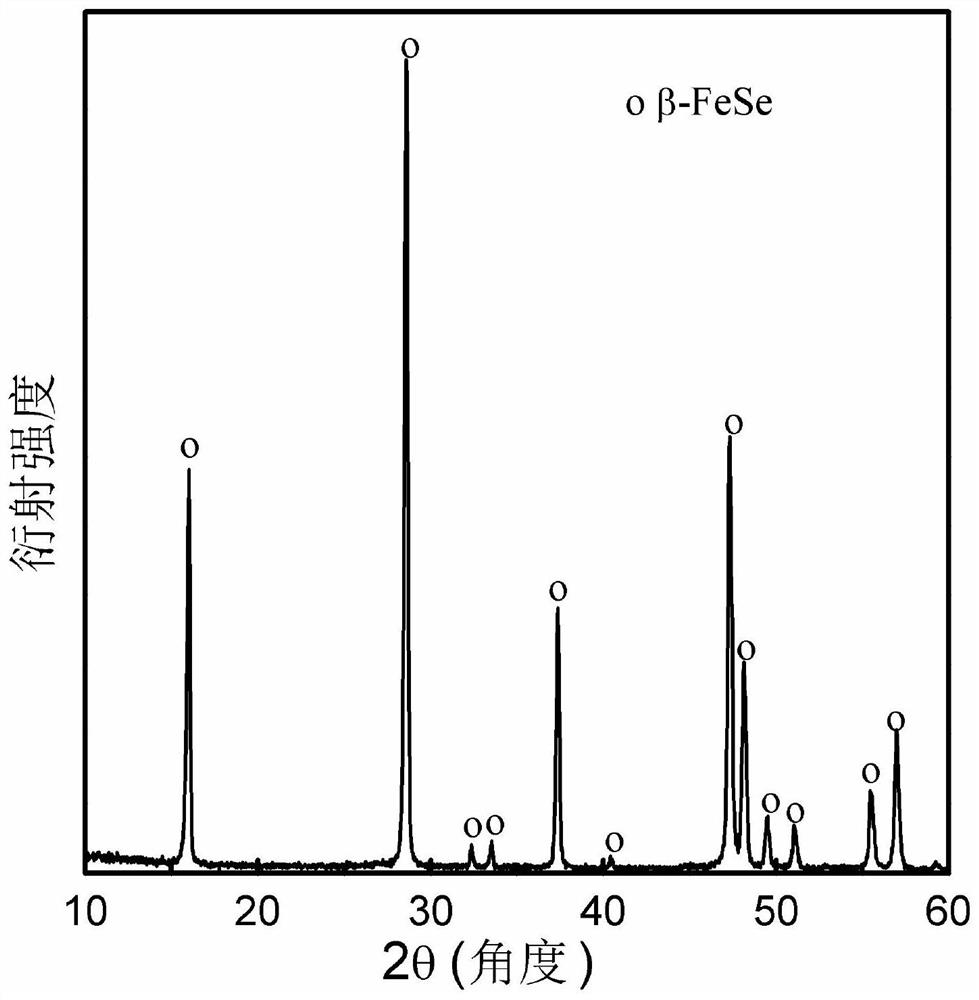

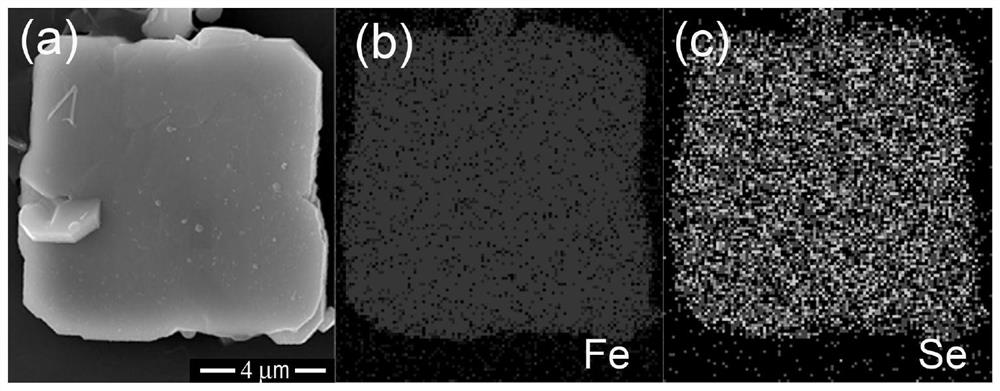

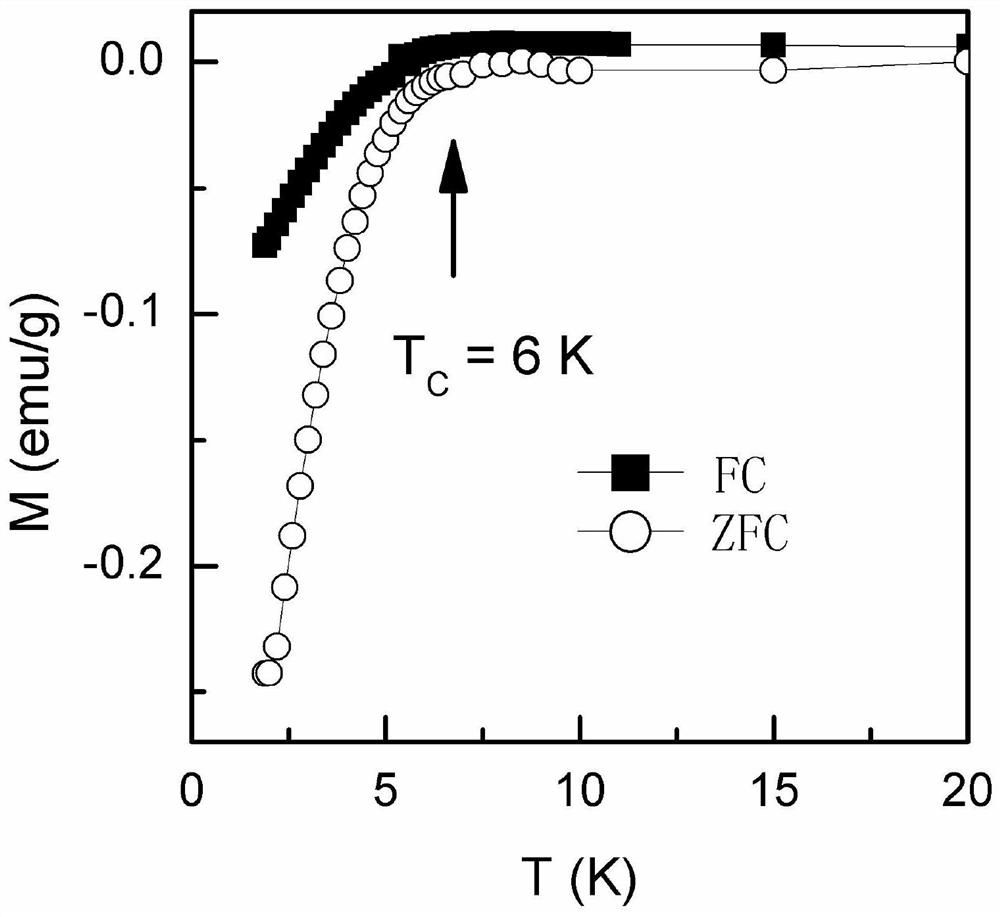

[0025] The crystal structure of the product was determined by x-ray diffraction, and the phase was determined to be β-FeSe with a tetragonal crystal structure, such as figure 1 shown. Its scanning electron microsco...

Embodiment 2

[0027] Selenium powder (0.5mmol), polyvinylpyrrolidone (50mg), cetyltrimethylammonium bromide (5mg), sodium hydroxide (5.5mmol) and ethylene glycol (10ml) were mixed, and the reaction kettle was sealed and heated to 433K, and keep it warm for 3 hours to obtain a selenium-ethylene glycol solution. Ferrous sulfate (0.375mmol) and ethylene glycol (10ml) were mixed and ultrasonically dissolved to obtain an iron-ethylene glycol solution. Mix the selenium-containing ethylene glycol solution and the iron-containing ethylene glycol solution, seal them in a 50ml solvothermal reaction kettle under a nitrogen atmosphere, heat the reaction kettle to 433K, and keep it warm for 12 hours, then heat it to 493K, and keep it warm After 72 hours, β-FeSe nanosheets were obtained. The β-FeSe nanosheets were centrifuged and washed 3 times with absolute ethanol, dried in vacuo, and stored in vacuo.

[0028] Transmission electron microscope (TEM) photos, high-resolution transmission electron micros...

Embodiment 3

[0030]Selenium powder (0.5mmol), cetyltrimethylammonium bromide (35mg), sodium hydroxide (5.5mmol) and ethylene glycol (10ml) were mixed, and the reaction kettle was sealed and heated to 433K, and kept for 3 hours , to obtain a selenium-ethylene glycol solution. Ferrous sulfate (0.375mmol) and ethylene glycol (10ml) were mixed and ultrasonically dissolved to obtain an iron-ethylene glycol solution. Mix the selenium-containing ethylene glycol solution and the iron-containing ethylene glycol solution, seal them in a 50ml solvothermal reaction kettle under a nitrogen atmosphere, heat the reaction kettle to 513K, and keep it warm for 24 hours to obtain β-FeSe nanosheets. The β-FeSe nanosheets were centrifuged and washed 3 times with absolute ethanol, dried in vacuo, and stored in vacuo.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com