A kind of preparation method of iron phosphate doped with nano-titanium dioxide

A nano-titanium dioxide, iron phosphate technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide and other directions, can solve the problems of low room temperature conductivity, low tap density, poor low temperature performance, etc., and achieve simple wastewater treatment. , The effect of high tap density and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

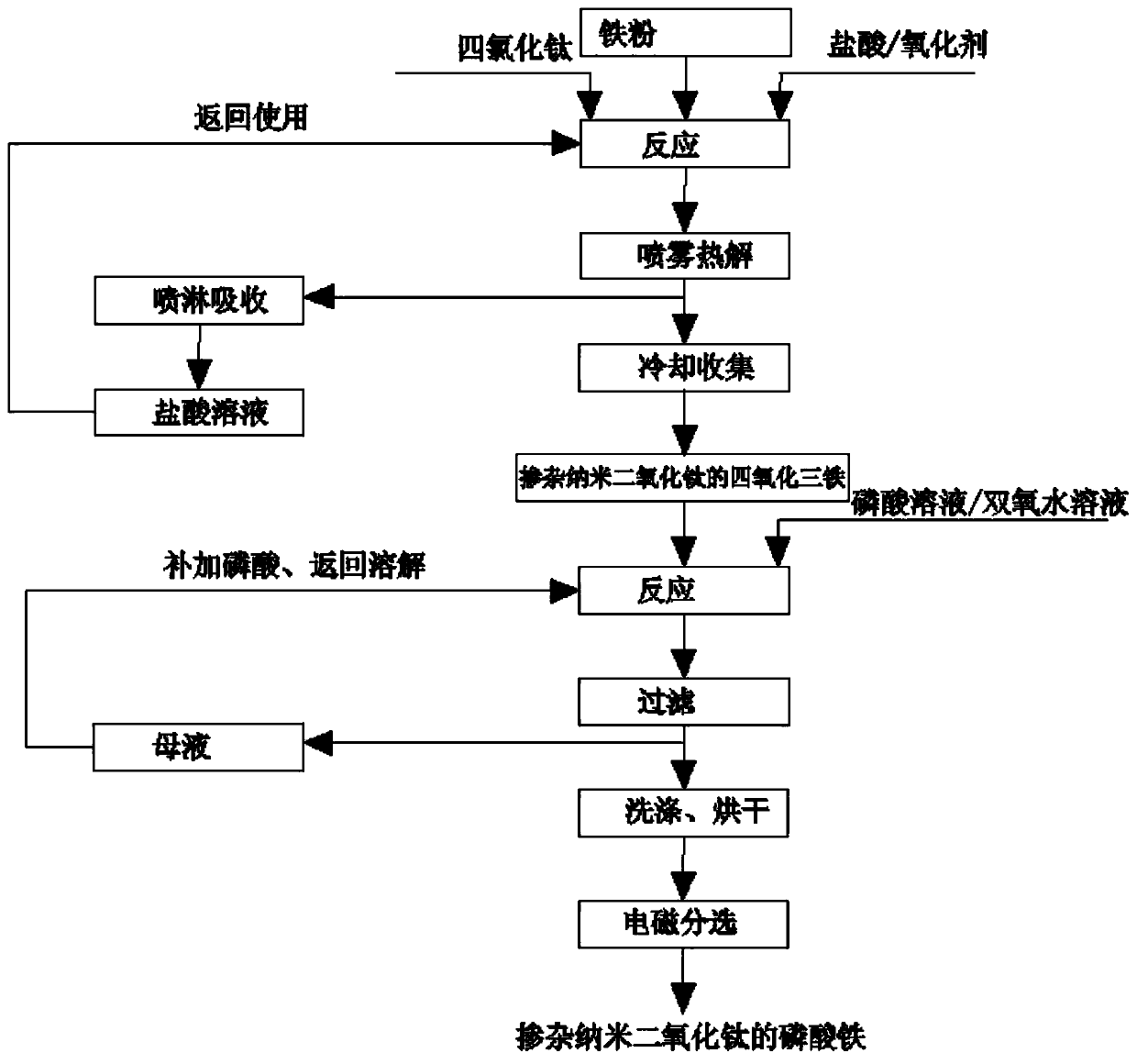

[0037] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 Shown: a kind of preparation method of the ferric phosphate doped with nano titanium dioxide of the present invention, it is the following steps:

[0038] (1) Add iron powder and titanium tetrachloride liquid to 5-6mol / L hydrochloric acid solution, maintain the temperature at 30-40°C for reaction, and filter after the iron powder is completely dissolved to obtain ferrous chloride and tetrachloride A mixed solution of titanium, then adding an oxidant so that the molar ratio of ferrous ions and ferric ions in the solution is 1:2;

[0039] (2) Add the mixed solution of ferrous chloride and titanium tetrachloride into a high-temperature sealed furnace by spraying, react at a temperature of 700-800°C, then extract it through an exhaust fan, and cool it to a temperature of 150-300°C ℃, collect ferric oxide solid particles doped with nano-titanium dioxide, and then ab...

Embodiment 1

[0049] A kind of preparation method of the ferric phosphate doped nano titanium dioxide of the present invention, it is the following steps:

[0050] (1) Add iron powder and titanium tetrachloride liquid into 5.5mol / L hydrochloric acid solution, maintain the temperature at 33°C for reaction, and filter after the iron powder dissolves completely to obtain a mixture of ferrous chloride and titanium tetrachloride solution, then add oxidant so that the mol ratio of ferrous ion and ferric ion in the solution is 1:2;

[0051] (2) Add the mixed solution of ferrous chloride and titanium tetrachloride into a high-temperature sealed furnace by spraying, react at a temperature of 700-800°C, then extract it through an exhaust fan, and cool it to a temperature of 185°C. Collect ferric oxide solid particles doped with nano-titanium dioxide, and then absorb the remaining gas through four-stage pure water spray to obtain hydrochloric acid solution;

[0052] (3) adding the iron ferric oxide s...

Embodiment 2

[0065] A kind of preparation method of the ferric phosphate doped nano titanium dioxide of the present invention, it is the following steps:

[0066] (1) Add iron powder and titanium tetrachloride liquid into 5.3mol / L hydrochloric acid solution, maintain the temperature at 35°C for reaction, and filter after the iron powder dissolves completely to obtain a mixture of ferrous chloride and titanium tetrachloride solution, then add oxidant so that the mol ratio of ferrous ion and ferric ion in the solution is 1:2;

[0067] (2) Add the mixed solution of ferrous chloride and titanium tetrachloride into a high-temperature sealed furnace by spraying, react at a temperature of 700-800°C, then extract it through an exhaust fan, and cool it to a temperature of 250°C. Collect ferric oxide solid particles doped with nano-titanium dioxide, and then absorb the remaining gas through 5-stage pure water spray to obtain hydrochloric acid solution;

[0068] (3) adding the iron ferric oxide soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electromagnetic force | aaaaa | aaaaa |

| electromagnetic force | aaaaa | aaaaa |

| electromagnetic force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com