Preparation method of monodisperse spherical nano zirconium dioxide powder material

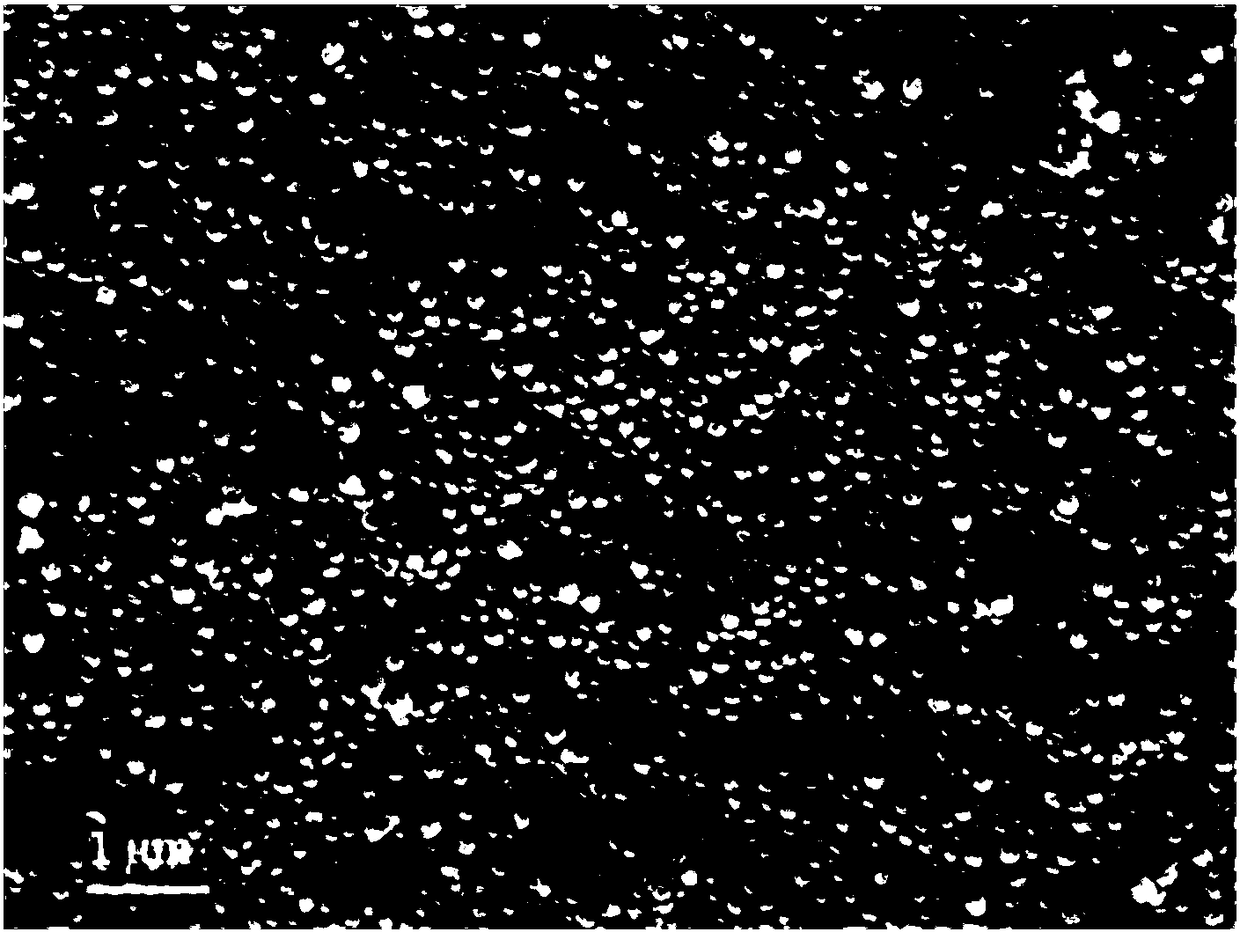

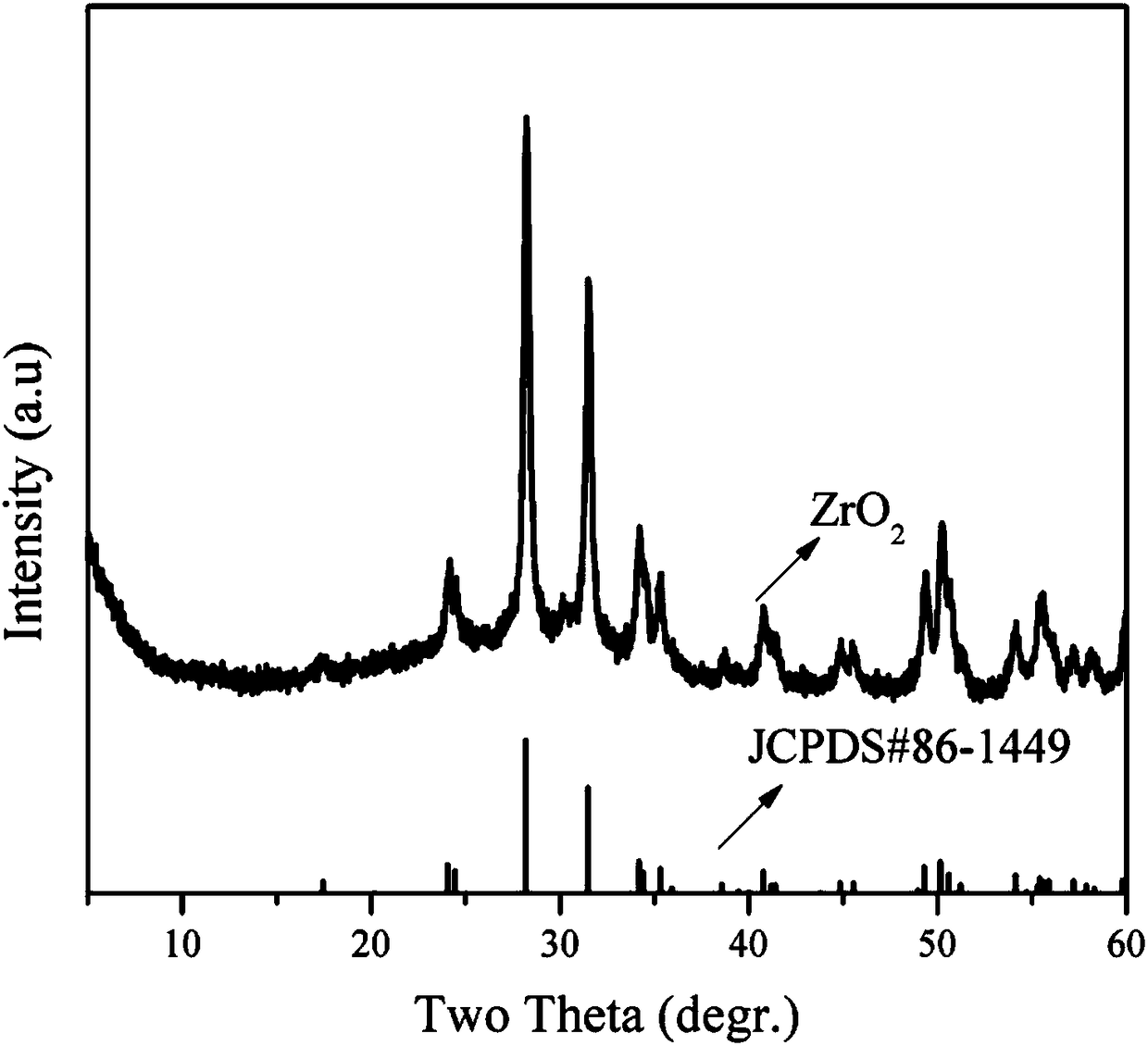

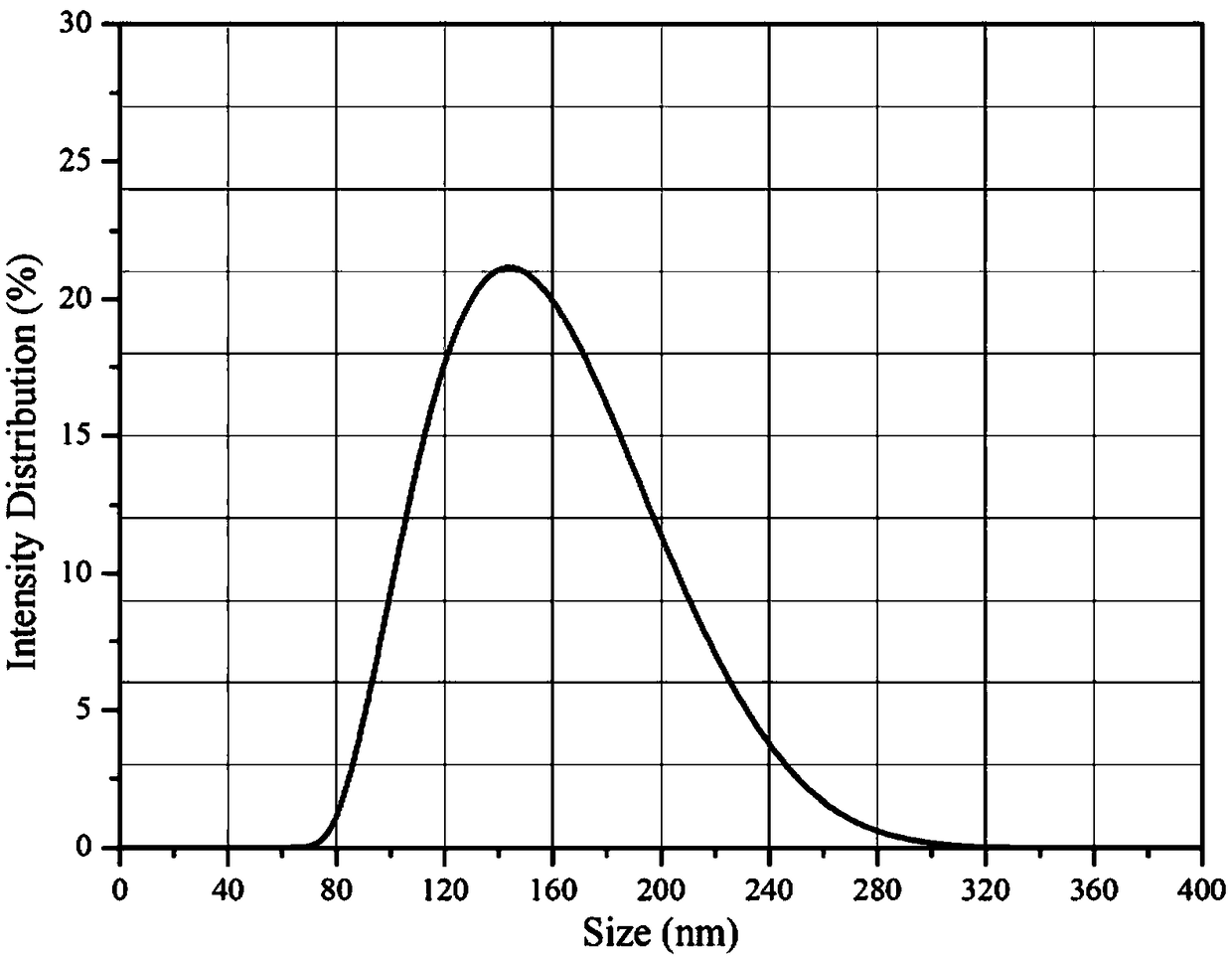

A technology of nano-zirconia and powder materials, applied in the direction of zirconia, nanotechnology, etc., can solve the problems of irregular shape, wide particle size distribution, poor dispersion of nano-zirconia, and achieve concentrated particle size distribution, single Excellent dispersibility effect and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] This embodiment provides a method for preparing a monodisperse spherical nano-zirconia powder material, comprising the following steps:

[0014] (1) The organic zirconium source, electrolyte solution and alcohol solution are prepared according to the volume ratio of 1-10:0.5-1.4:50-100, and the alcohol solution is divided into 2 parts; in an inert gas environment, the inert gas is preferably nitrogen, Add the organic zirconium source and the electrolyte solution to 2 parts of the alcohol solution respectively, stir and mix evenly when the temperature is 20-80°C, and the preferred mixing temperature is 50°C to obtain the A mixed solution (the mixed solution of the organic zirconium source-alcohol solution) and B mixed solution (mixed solution of electrolyte solution-alcoholic solution);

[0015] Organic zirconium sources include zirconium tetraethoxide, zirconium n-propoxide, zirconium isopropoxide, zirconium tetraisopropoxide, zirconium n-butoxide, zirconium tert-butoxi...

Embodiment 1

[0023] This embodiment provides a method for preparing a monodisperse spherical nano-zirconia powder material, comprising the following steps:

[0024] (1) KCl is made into the KCl solution of 0.3mol / L, according to the volume ratio of n-butoxide zirconium (IV), KCl solution and n-butanol solution is 2: 1: 80 to prepare materials, and alcoholic solution is divided into 2 parts; Under the protection of nitrogen atmosphere, add zirconium n-butoxide and KCl solution to 2 parts of n-butanol solution respectively, and keep stirring at 50°C for 30 minutes to obtain uniformly mixed A mixed solution and B mixed solution;

[0025] (2) Drop the mixed solution B in step (1) into the mixed solution A at a speed of 10d / s, and continue to stir the mixed solution for 1 hour, then raise the temperature to 70°C to start aging, and continue to age for 8 hours. After the reaction is completed, The obtained product is centrifuged, washed, and vacuum-dried to obtain the zirconia precursor powder; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap