Rutile type high color saturation interference color pearlescent pigment and preparation method thereof

A technology of rutile-type and pearlescent pigments, which is applied in the field of pearlescent pigments, can solve the problems of insufficient heat resistance and weather resistance of anatase-type pearlescent pigments, performance differences of pearlescent pigments, and insufficient bright colors, etc., to achieve bright colors and enhance Pigment purity, effect of enhancing finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

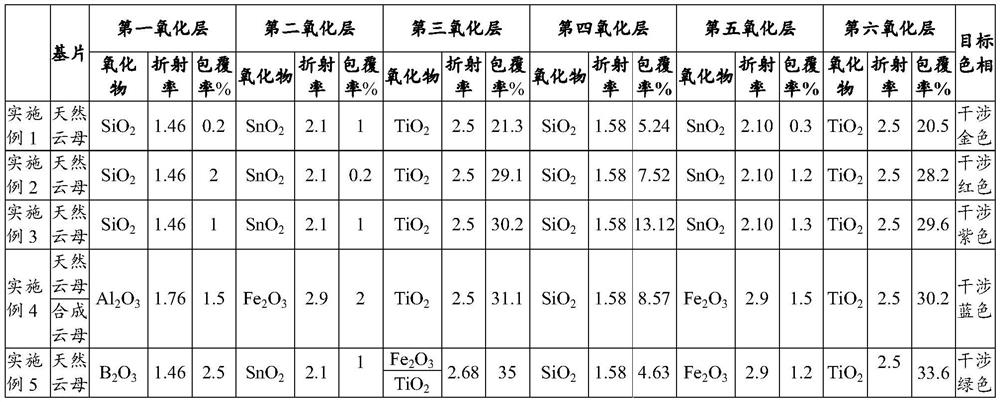

Examples

Embodiment 1

[0034] The structure is: natural mica + SiO 2 +SnO 2 +TiO 2 +SiO2 2 +SnO 2 +TiO 2

[0035] 1) Put natural mica flakes with a particle size of 20 to 80 μm into a reaction kettle filled with deionized water with a conductivity of less than 30 μS / cm, stir to form a suspension with a solid-to-liquid weight ratio of 1:10, and stir and heat to 80°C , to obtain the first suspension;

[0036] 2) Adjust the pH value of the first suspension to 6 with 32% NaOH solution under stirring conditions, add sodium silicate aqueous solution at a certain rate, and keep the system pH constant with 20% dilute hydrochloric acid, continue stirring after adding, and obtain the second suspension;

[0037] 3) Use 20% dilute hydrochloric acid to adjust the pH value of the second suspension to 2, add an aqueous solution of tin tetrachloride at a certain rate, use 32% NaOH solution to maintain a stable pH value, and continue stirring after adding to obtain a third suspension;

[0038] 4) Use 32% NaO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com