Device for codelessly assembling and automatically positioning U-shaped ribbed plate unit

An automatic positioning and rib technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of impossible replacement of steel bridge decks, difficult repairs, and affecting the service life of bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

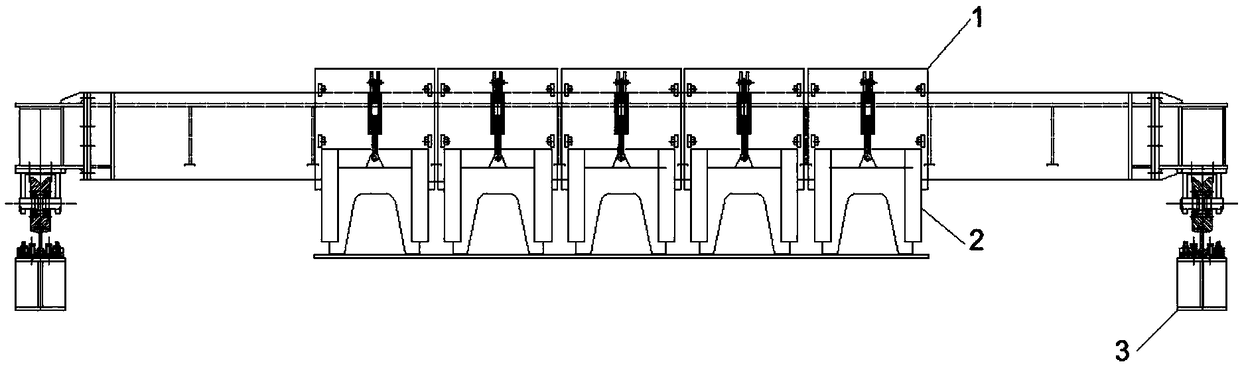

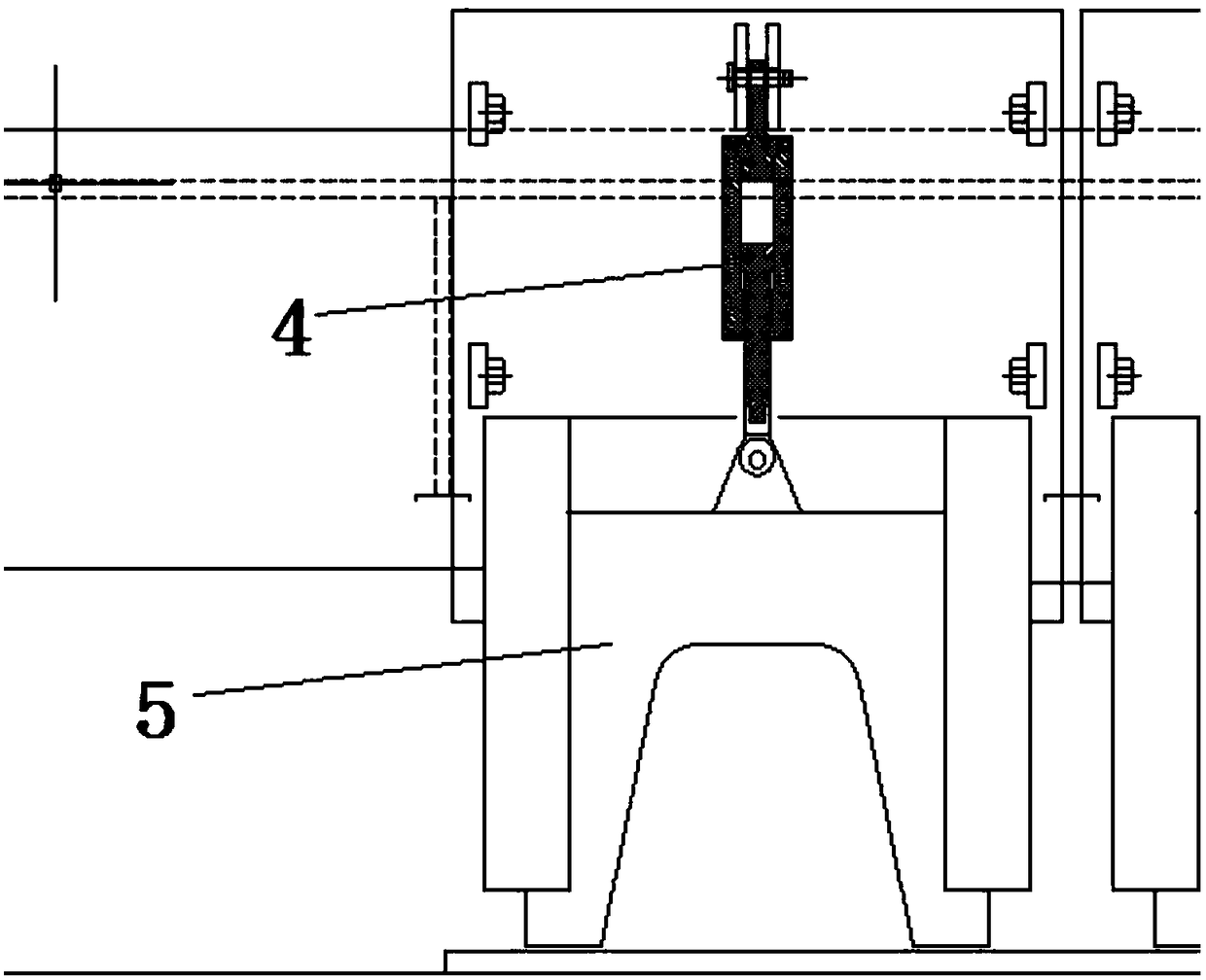

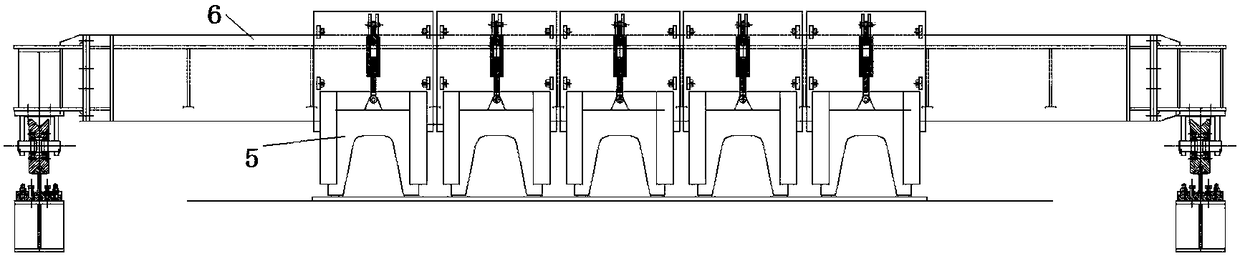

[0012] A device for automatically positioning a U-rib unit without code assembly, the device includes a hydraulic pressing system 2, a U-rib positioning system 1 and an electric walking system 3; the positioning system track 6 is the main structure of the electric walking system 3, and the positioning system track 6 Both ends are driven by hydraulic cylinders.

[0013] The U-rib positioning system 1 is connected with the hydraulic pressing system 2, and the hydraulic pressing system 2 is installed on the positioning system track 6. The hydraulic pressing system 2 is composed of multiple sets of hydraulic pressing units, and each hydraulic pressing unit is arranged side by side on the positioning system track 6; each hydraulic pressing unit is composed of a hydraulic jack 4 and a U rib clamp 5, and the hydraulic jack 4 is installed On the U-rib fixture 5, the U-rib fixture 5 is clamped on the U-rib plate.

[0014] Such as figure 1 shown by image 3 The positioning system tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com