Pulsation-free high-order elliptical cam pump

An elliptical cam, cam pump technology, applied to pumps, rotary piston type/swing piston type pump parts, pump components, etc., can solve the problems of overall weight increase, flow pulsation, inconvenience in processing, etc., to achieve large displacement, instantaneous The effect of smooth flow and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described below with reference to the drawings and embodiments.

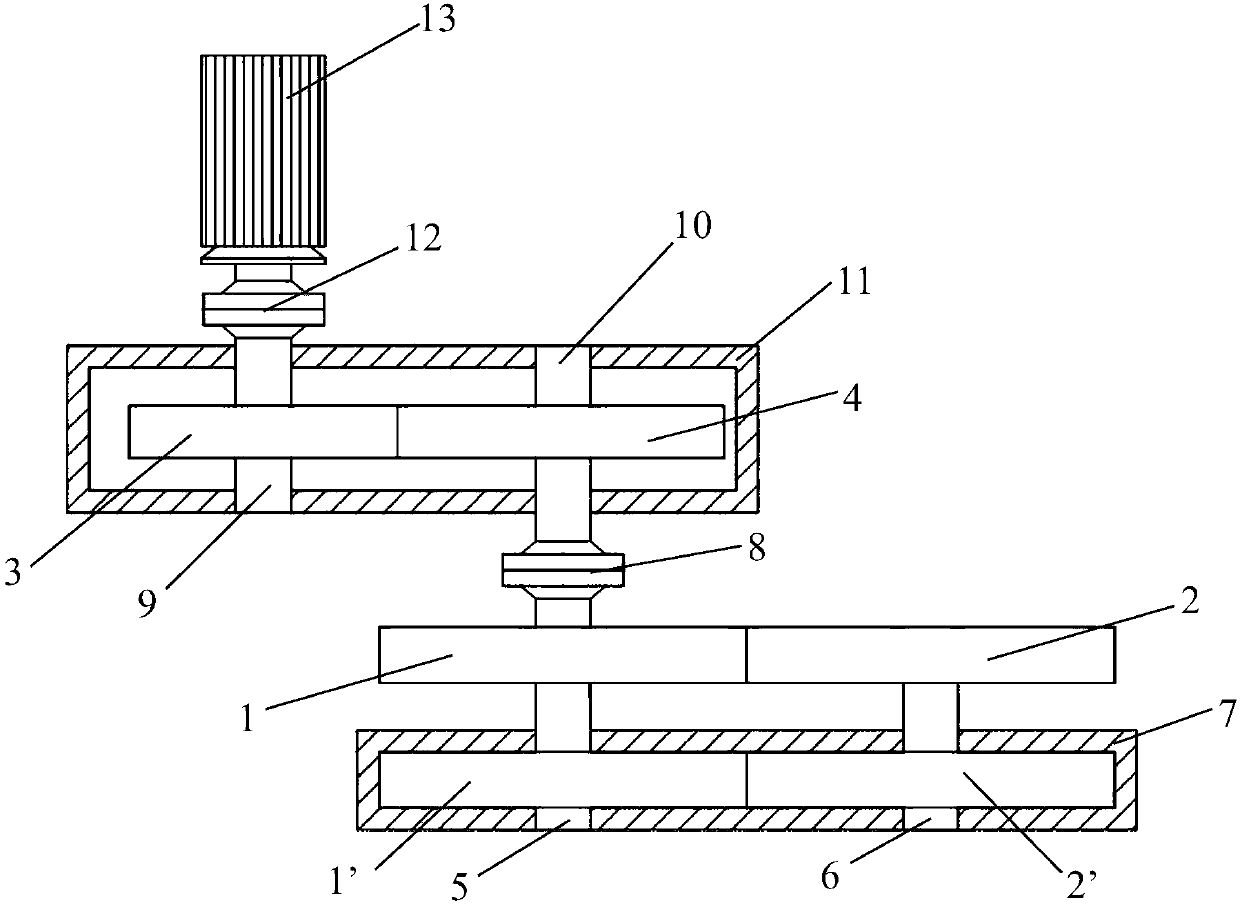

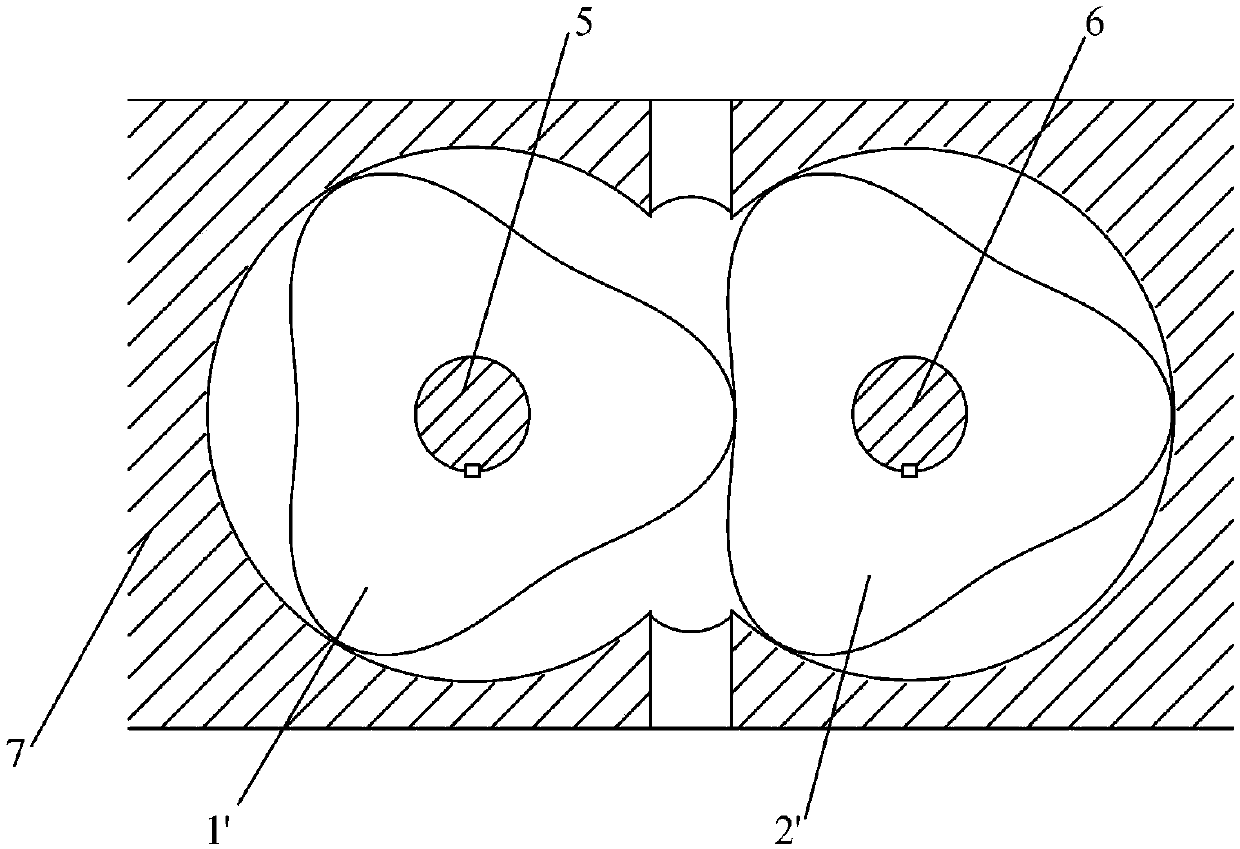

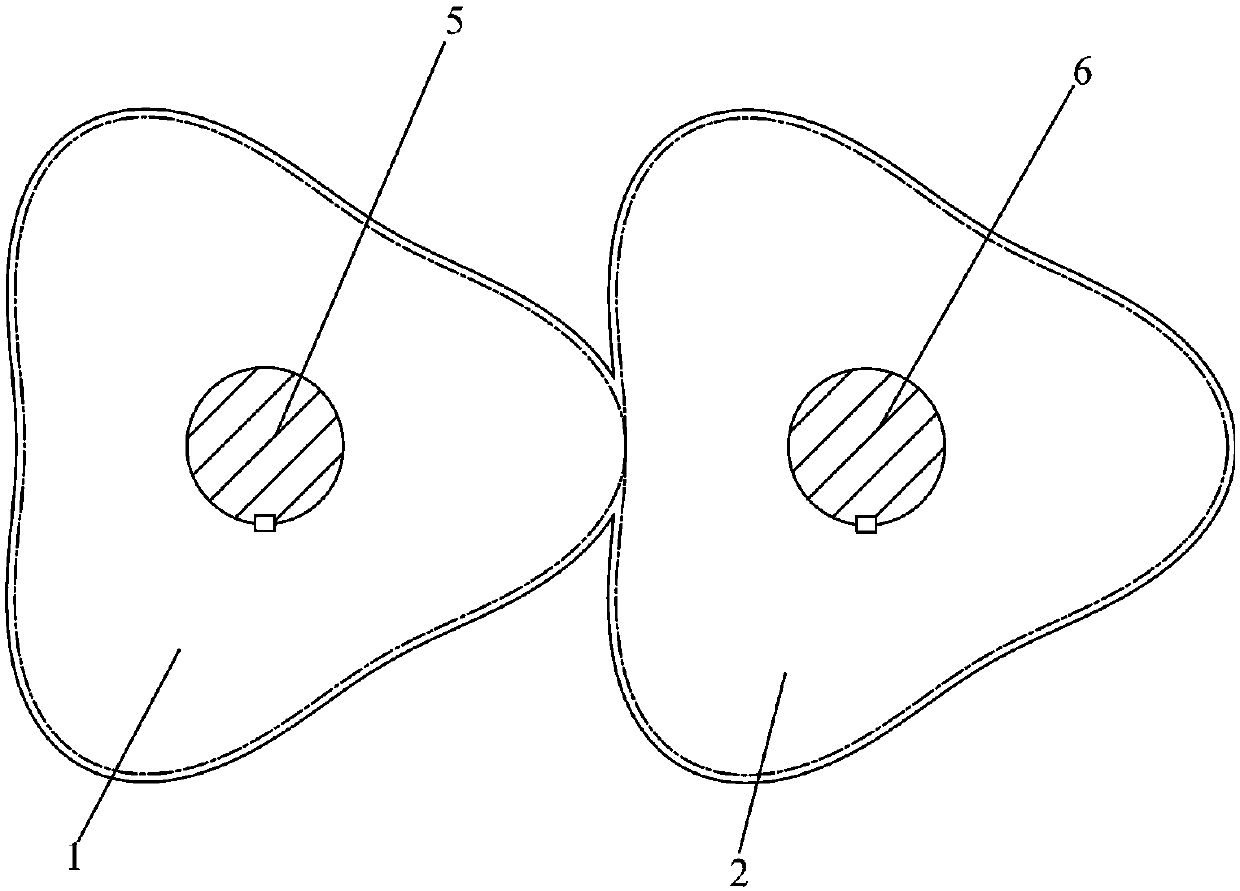

[0026] The specific structure of the high-order elliptical cam pump driven by the non-circular gear transmission is as follows figure 1 As shown, the high-end oval lobe pump driven by the non-circular gear transmission is mainly composed of three parts: a motor, a transmission and a lobe pump. Among them, the lobe pump consists of high-order elliptic cam rotor A1', high-order elliptic cam rotor B2', high-order elliptic gear pump driving shaft 5, high-order elliptic gear pump driven shaft 6, active synchronous high-order elliptic gear 1, driven The synchronous high-order ellipse gear 2 and the pump body 7 are composed of a high-order elliptic gear pump driving shaft 5 and a high-order elliptic gear pump driven shaft 6, a high-order elliptical cam rotor A1' and a high-order elliptical cam rotor B2 in the pump body 'Placed inside the pump body, one end of the high-order ell...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap