Defect detection method and detection device of printed circuit board and storage medium

A technology for printed circuit boards and detection methods, applied in image data processing, instruments, biological neural network models, etc., can solve the problems of high false alarm rate and low detection efficiency of circuit board defects, and achieve the effect of improving efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

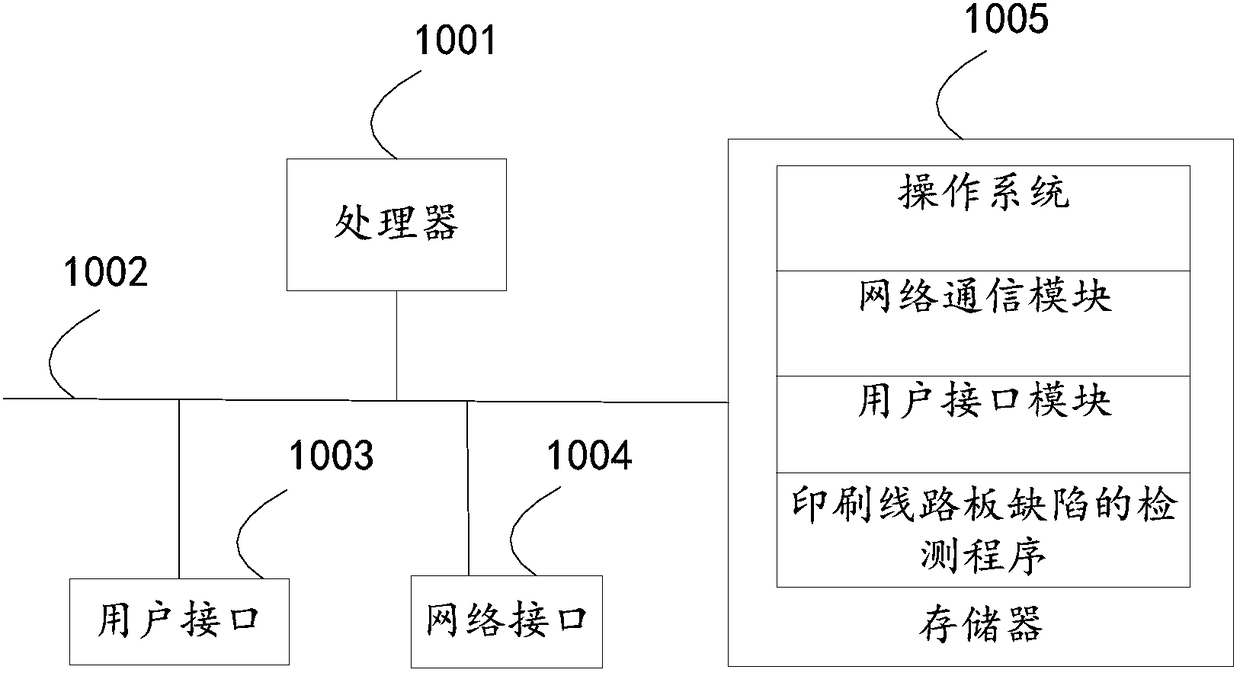

[0041] Reference figure 1 , figure 1 It is a schematic diagram of the structure of the detection device of the hardware operating environment involved in the solution of the embodiment of the present invention.

[0042] Such as figure 1 As shown, the detection device may include: a processor 1001, the processor may be a central processing unit (Central Processing Unit, CPU), a graphics processing unit (Graphics Processing Unit, GPU), or a tensor processing unit Tensor Procession Unit (TPU) and Field Programmable Gate Array (FPGA), communication bus 1002, user interface 1003, network interface 1004, memory 1005. Among them, the communication bus 1002 is used to implement connection and communication between these components. The user interface 1003 may include a display screen (Display) and an input unit such as a ke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap