Technology for anodizing thick TA2 titanium alloy material film

An anodizing, titanium alloy technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

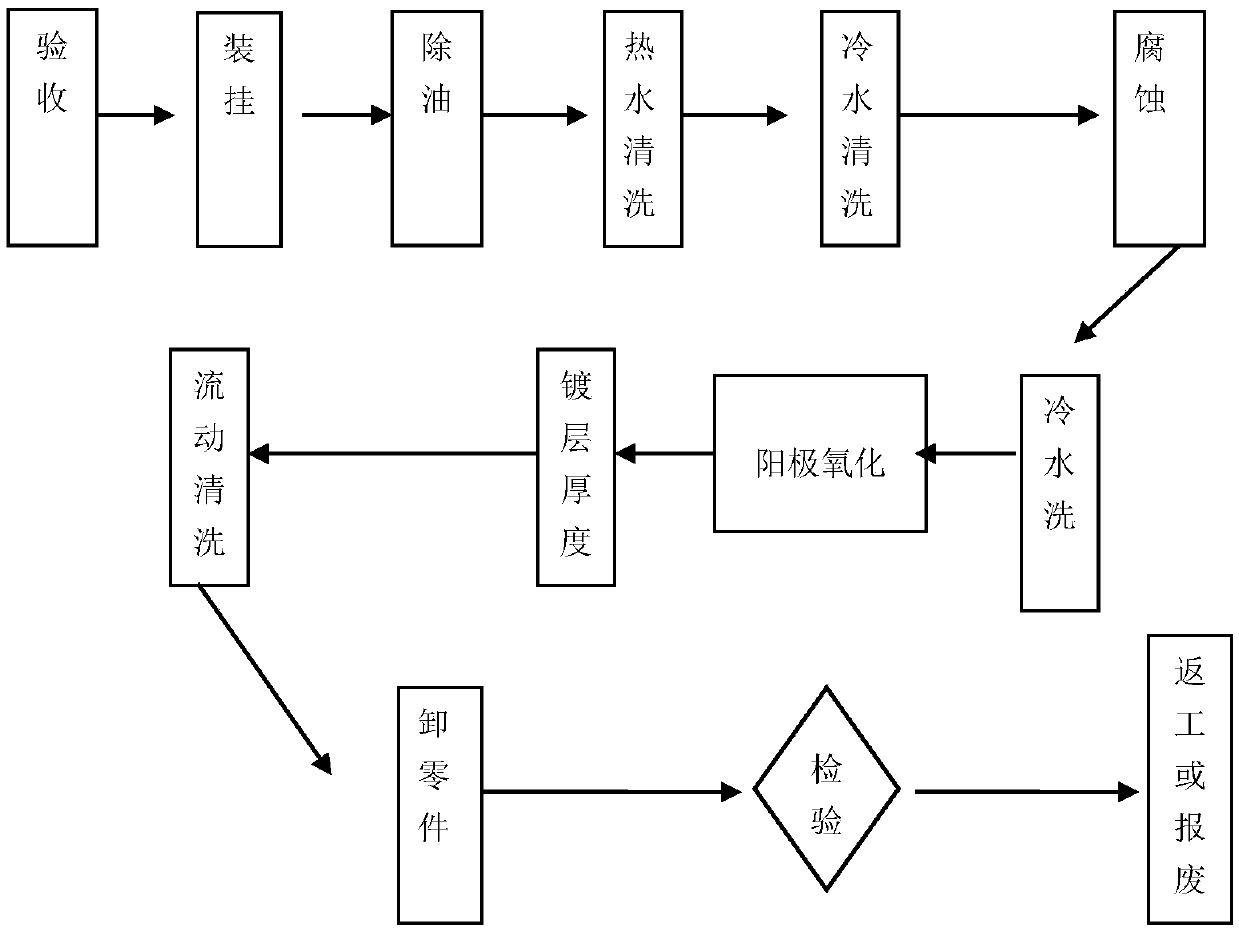

[0037] 1) The present invention is a bath solution formula and anodization process method for TA2 titanium alloy thick film anodization. Anodize the XX03020-20-01 part.

[0038] 2) The bath formula is:

[0039] Sulfuric acid (H 2 SO 4 , ρ=1.84g / mL) according to 200mL / L preparation;

[0040] Phosphoric acid (H 3 PO 4 , ρ=1.7g / mL) according to 20mL / L preparation;

[0041] Ti 4+ <5 g / L;

[0042] The rest is distilled or deionized water.

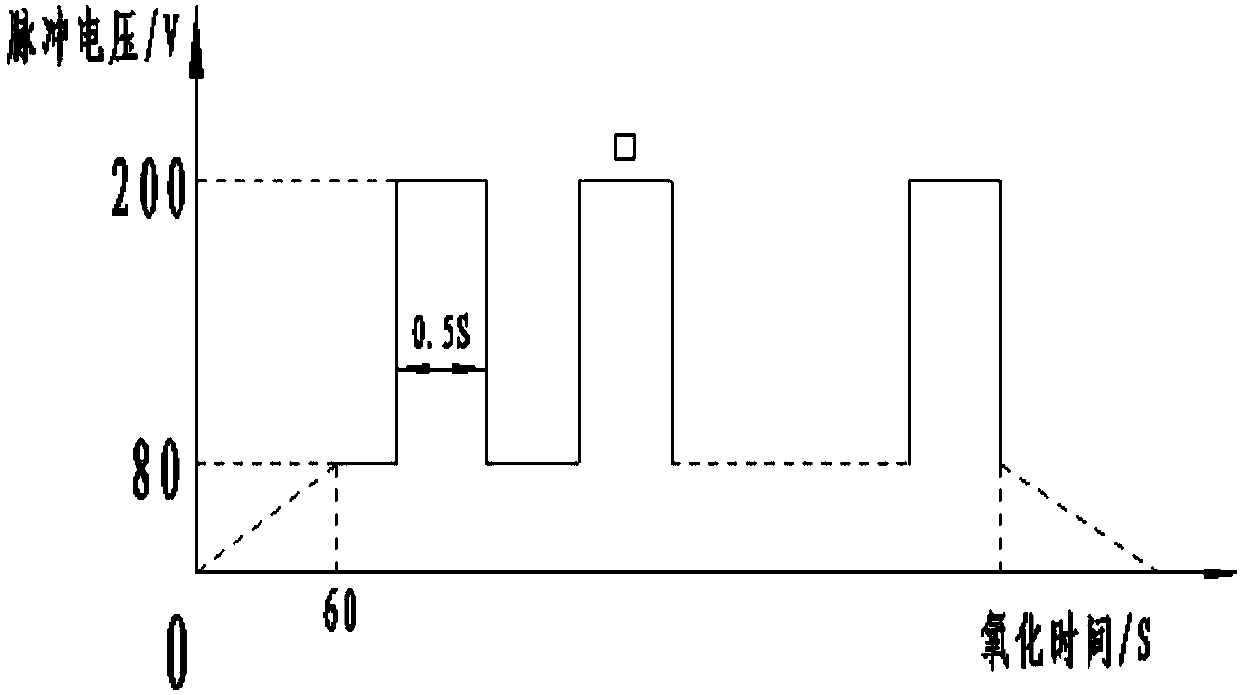

[0043] Anodizing by pulse superposition: pulse voltage 200V, duty ratio 1 / 2;

[0044] Anodizing temperature: 6°C;

[0045] compressed air stirring;

[0046] Anodizing time (excluding slow start time and slow down time): 50min;

[0047] Slow start time: 1min;

[0048] Slow down time: 1min;

[0049] After energization, the voltage should rise to 80V within 1 minute, and the pulse superposition method should be used for anodizing. The pulse time is 0.5 seconds. The pulse superposition method should be used for anodizing.

[0050] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com