Low cost and convenient welding head for heat exchanger

A heat exchanger, low-cost technology, applied in the direction of pipes/pipe joints/fittings, non-removable pipe connections, pass-through components, etc., can solve the requirements of welders' care and experience are very high, difficult to control welding conditions, affect welding effect and other problems, to achieve the effect of low replacement cost, simple and ingenious structure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

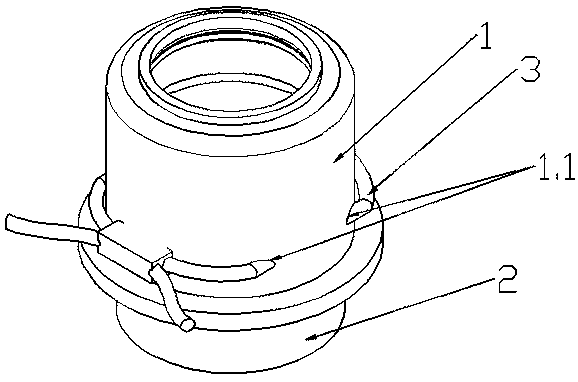

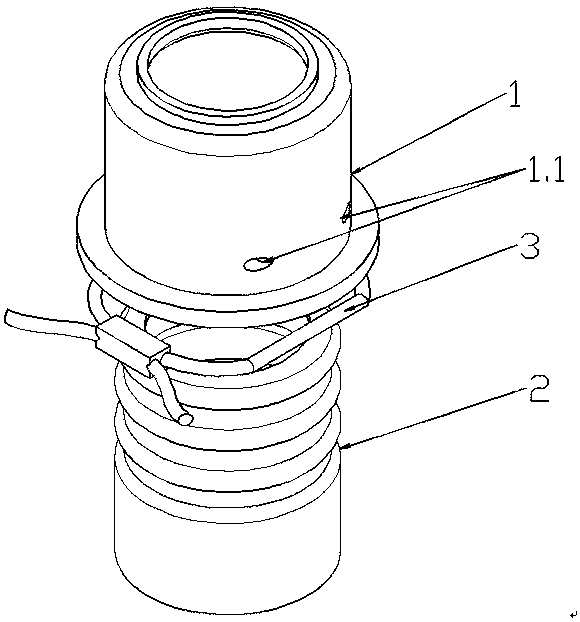

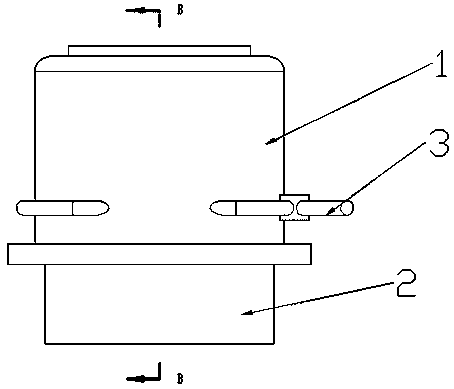

[0019] Such as Figure 1-Figure 4 As shown, the convenient welding joint for a low-cost heat exchanger includes a bottom buckle 1 whose bottom is fixed at the inlet or outlet of the heat exchanger end plate and a copper pipe joint 2 whose top is connected to a copper pipe. The bottom buckle 1 is provided with at least one pair of perforations 1.1. The bottom of the copper pipe joint 2 is inserted into the bottom buckle 1 and is sealed with the bottom of the bottom buckle 1 through an O-ring. The copper pipe joint 2 is thin The wall metal pipe is extruded and contains a copper layer at least on its top, and the bottom of the copper pipe joint 2 is provided with at least one first annular groove 2.1, and the O-ring is arranged in the first annular groove 2.1 Inside, the copper pipe joint 2 is also provided with at least one second annular groove 2.2, the position of the second annular groove 2.2 is in line with the paired perforation 1.1 on the bottom buckle 1 when the bottom of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap