Linear anisotropic magnetoresistive sensor and preparation method thereof

An anisotropic magnetic and sensor technology, used in instruments, measuring magnetic variables, measuring devices, etc., can solve the problem of less noise in the output signal of the conductive layer, and achieve the effect of clear current direction, less noise in the output signal, and thin conductive layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

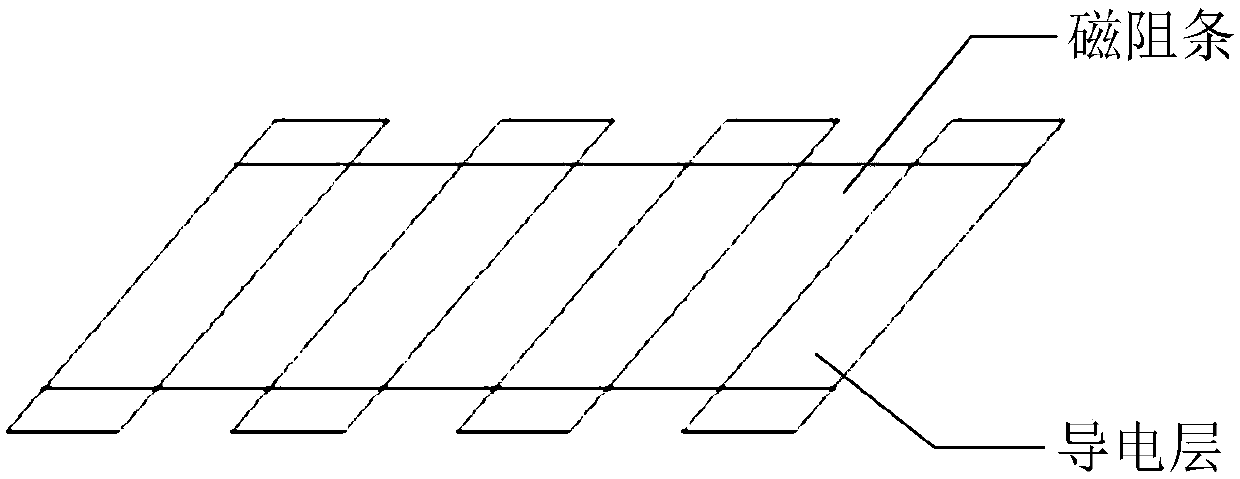

[0027] Step 1: On the silicon substrate, a pattern of elongated magnetoresistive strips with a total length of 7.2um and discontinuous strips is exposed by a photolithography process, each magnetoresistive strip has a width of 5nm and a gap of 5nm.

[0028] Step 2: Deposit 5nmTa, 12nmNiFe and 2nmTa in sequence on the substrate treated in step 1 by magnetron sputtering process. Then it is soaked in the glue removing solution, and after the photoresist is removed, the sample is taken out to obtain discontinuous elongated magnetoresistive strips.

[0029] Step 3: On the substrate processed in step 2, a 20nm Al conductive layer is filled at the position of the non-magnetoresistive strips by using a photolithography process and an electron beam evaporation process, and the magnetoresistive strips are electrically connected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com