Intelligent fastener and monitoring system thereof

A technology for monitoring systems and fasteners, applied to threaded fasteners, measuring devices, connecting components, etc., can solve the problems of large errors in judgment methods, high costs, troublesome use, etc., and achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

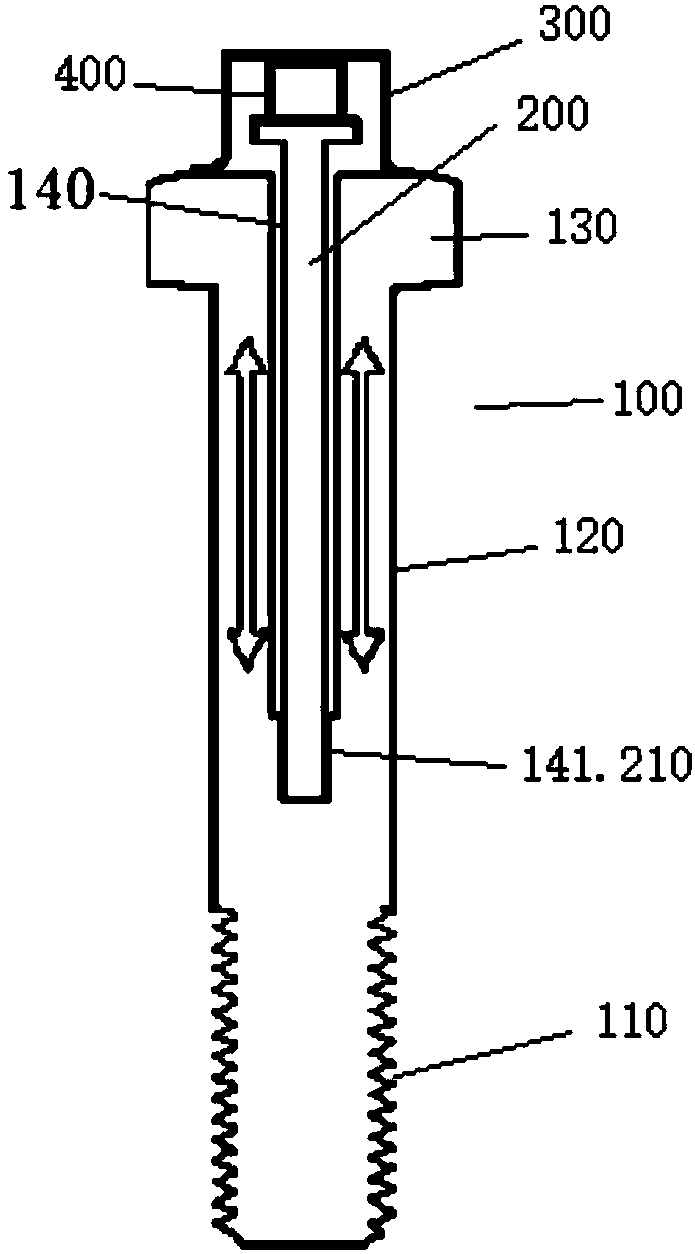

[0033] see figure 1 The shown intelligent fastener includes a fastener body. The fastener body includes a deformation part and a connecting part. The deformation part is connected to a measuring unit. When the fastener body is installed, the connecting part drives the deformation part to deform and then Prompting the measuring unit to move generates a displacement, and after the displacement is obtained, the pretightening force is calculated by manual calculation or a predetermined formula. The fastener body in this embodiment is a bolt body 100. The bolt body 100 sequentially includes a threaded section 110, a middle polished rod section 120, and a head 130 from the first end to the second end. The middle polished rod section 120 of the bolt body 100 is deformed. The threaded section 110 at one end of the bolt body 100 is the connecting portion, and the head 130 of the bolt body 100 is the fixed end. Therefore, when the fastener body is installed, the connecting portion of th...

Embodiment 2

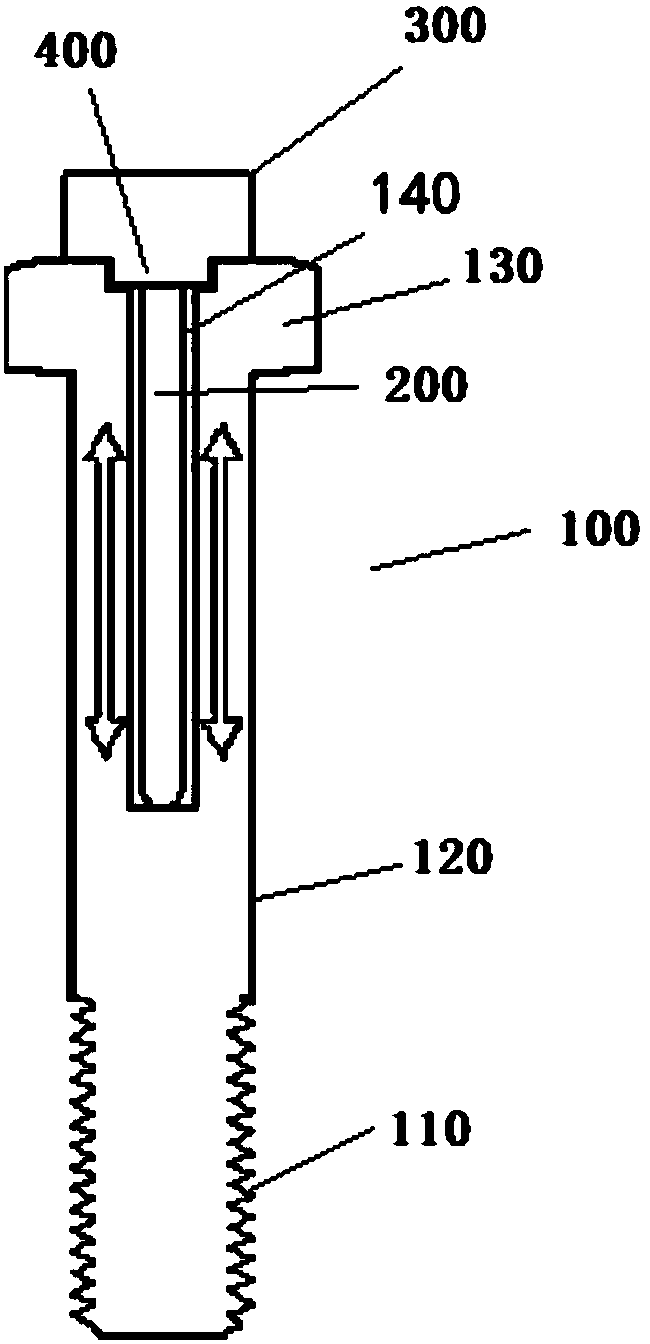

[0038] see figure 2 The shown intelligent fastener includes a fastener body. The fastener body includes a deformation part and a connecting part. The deformation part is connected to a measuring unit. When the fastener body is installed, the connecting part drives the deformation part to deform and then Prompting the measuring unit to move generates a displacement, and after the displacement is obtained, the pretightening force is calculated by manual calculation or a predetermined formula. The fastener body in this embodiment is a bolt body 100. The bolt body 100 sequentially includes a threaded section 110, a middle polished rod section 120, and a head 130 from the first end to the second end. The middle polished rod section 120 of the bolt body 100 is deformed. The threaded section 110 at one end of the bolt body 100 is the connecting portion, and the head 130 of the bolt body 100 is the fixed end. Therefore, when the fastener body is installed, the connecting portion of t...

Embodiment 3

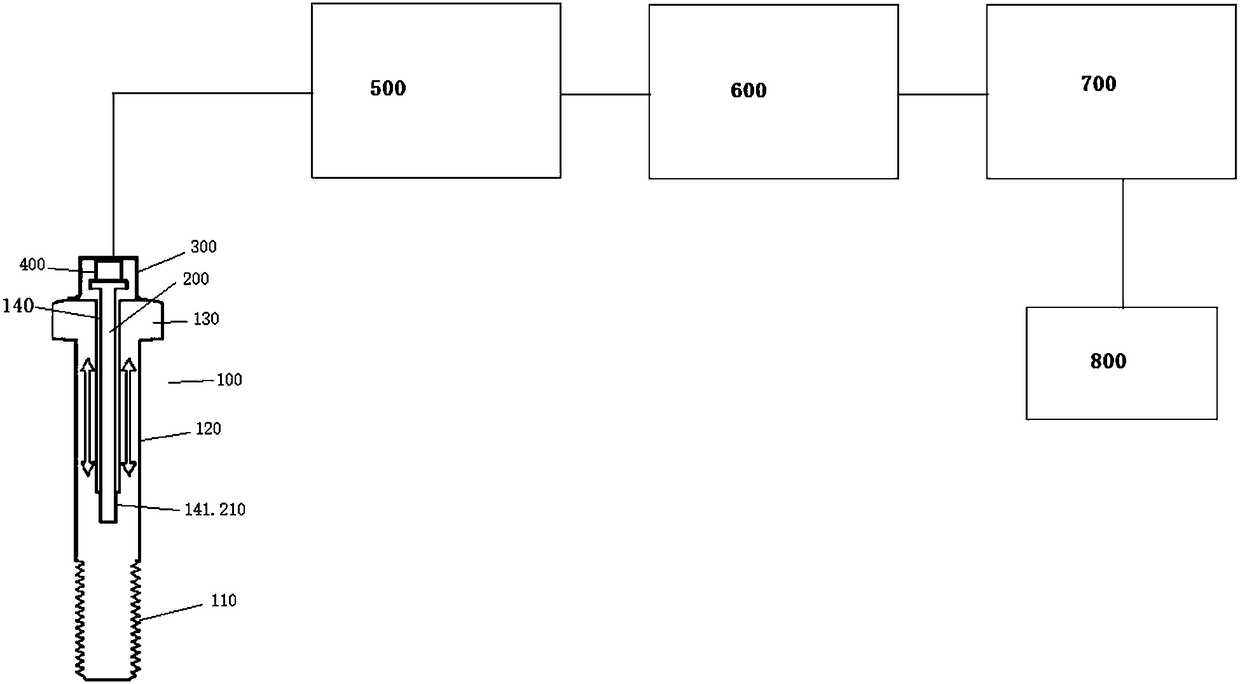

[0042] see image 3 The shown monitoring system for an intelligent fastener includes at least one intelligent fastener as in Embodiment 1 above and a data processing system capable of processing the displacement acquired by the intelligent fastener. The way the data processing system processes the displacement obtained by the smart fastener includes but is not limited to calculating the displacement to obtain the pretightening force of the smart fastener or directly obtaining and displaying the displacement.

[0043] The data processing system in this embodiment includes a data receiving end 500, a data processor 600, and a remote server 700. The data receiving end 500 is connected to the displacement measuring device 400 by wired or wireless means, and the data receiving end 500 sends the data to the data processing system. Processor 600 to convert the displacement data acquired by the smart fastener into the pre-tightening force of the smart fastener or directly displayed da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com