Process cartridge and electronic photographing imaging equipment

A technology for electrophotography and imaging equipment, applied in the field of electrophotographic imaging equipment, can solve the problems of complex assembly, easy scattering of parts, and many parts, and achieves the effects of improving smoothness, improving printing quality, and avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

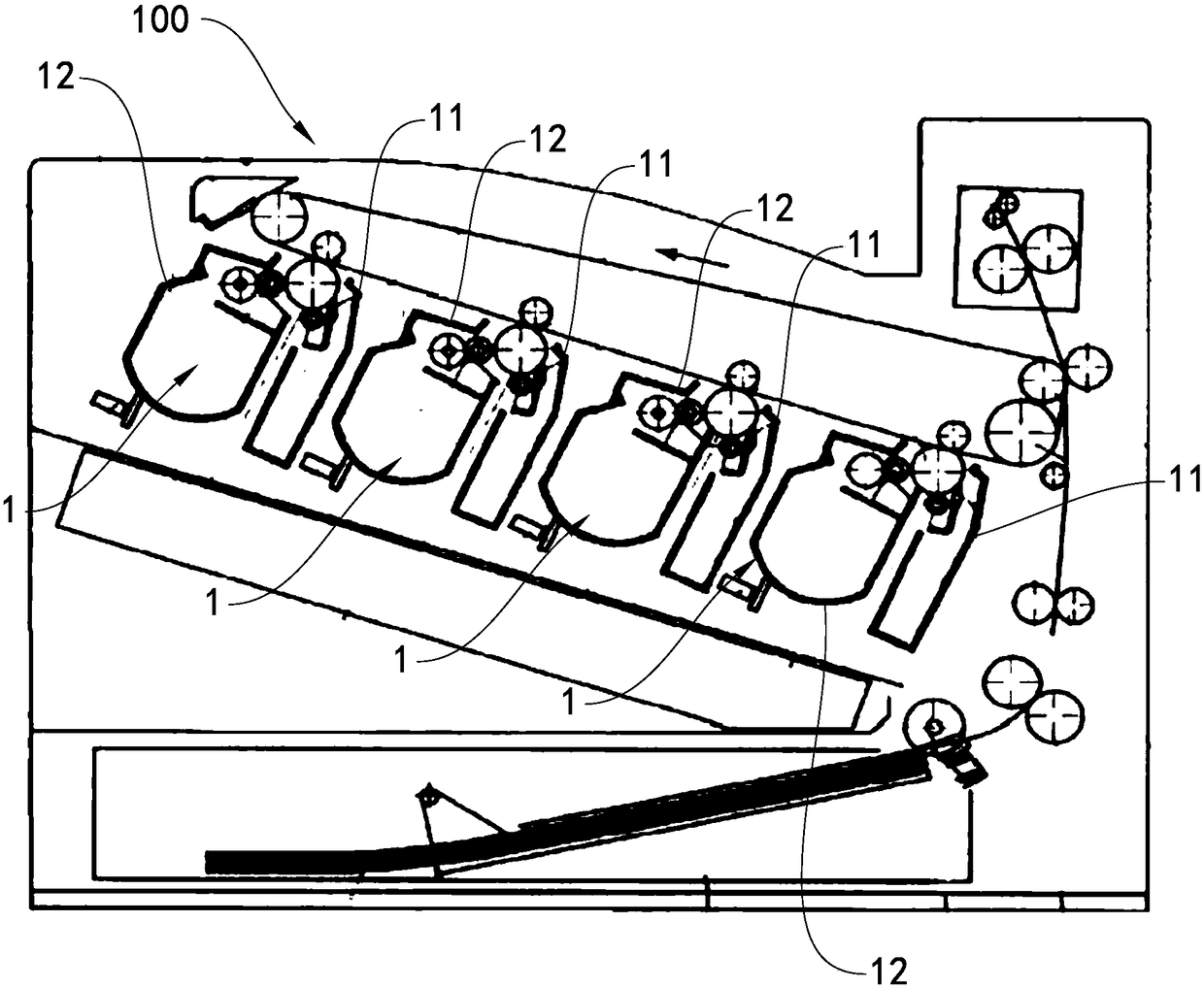

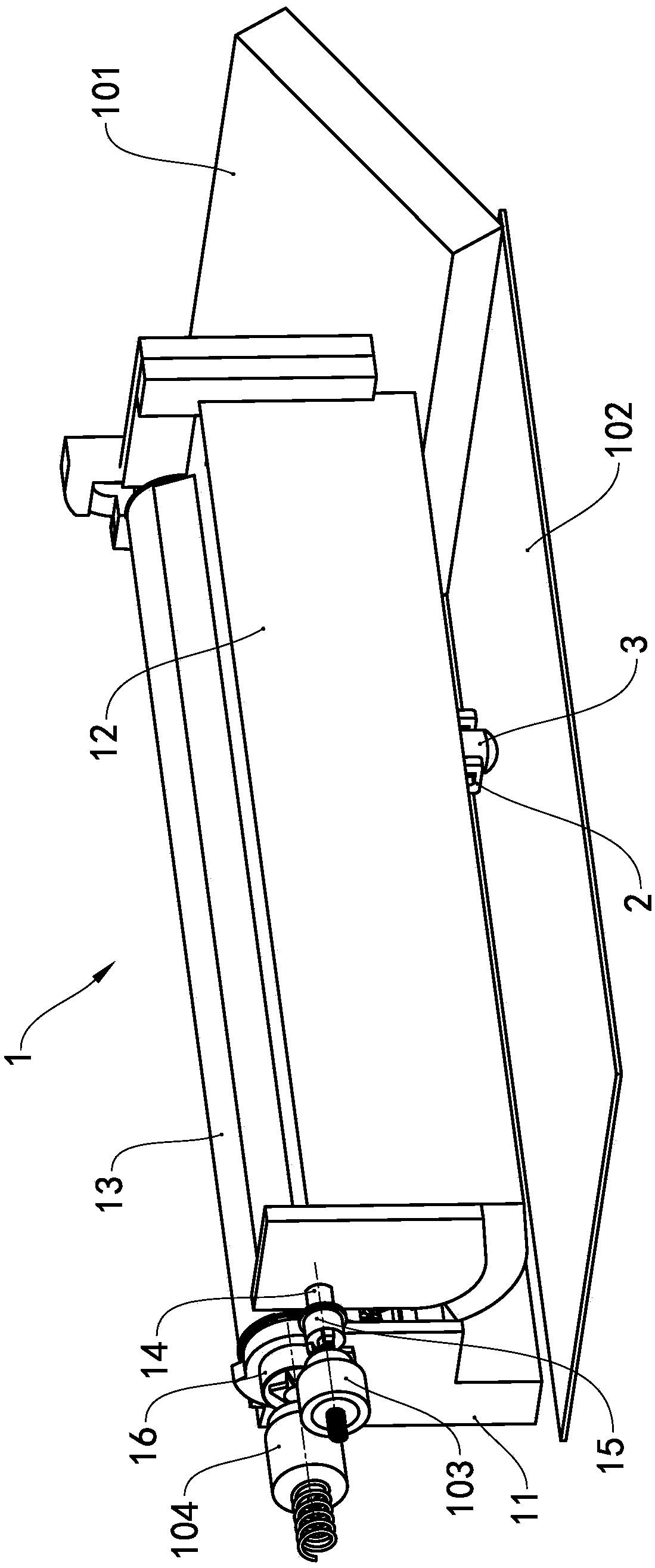

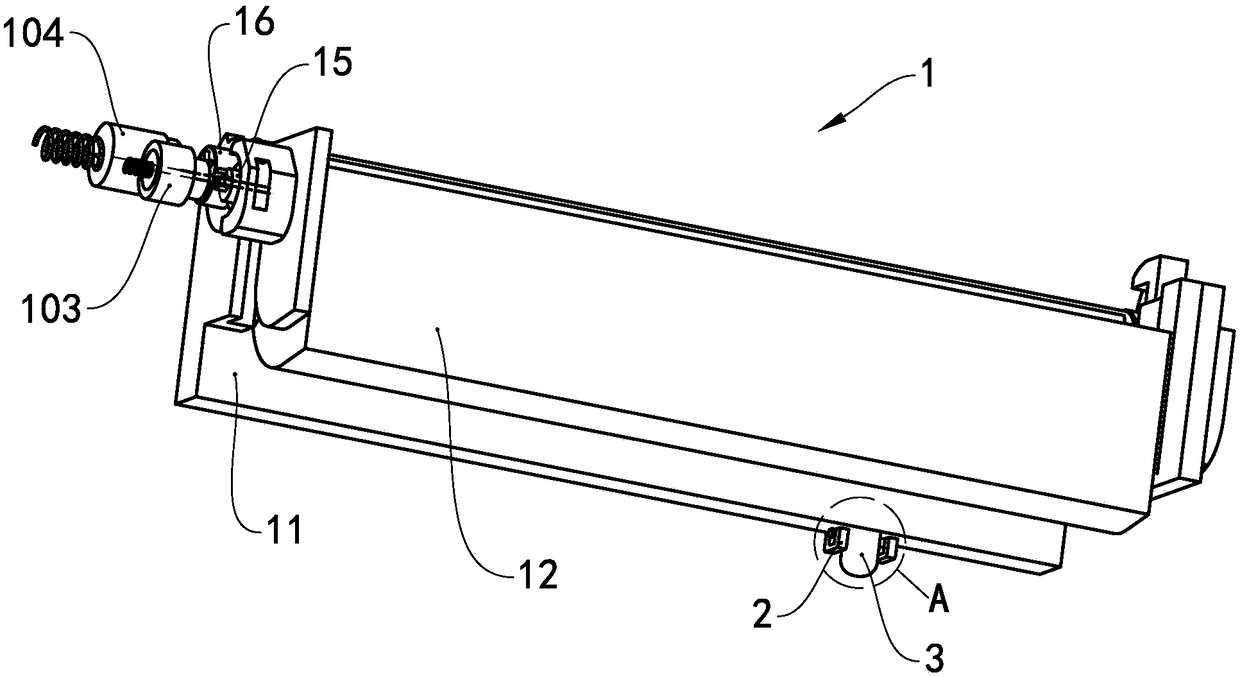

[0030] See Figure 1 to Figure 3 , figure 1 The state in which the process cartridge of this embodiment is installed in an electrophotographic image forming apparatus is shown. The electrophotographic image forming apparatus of this embodiment is a printer 100, and the process cartridge 1 is detachably installed in the printer 100. The printer 100 includes a rotatable first transmission head 104, a rotatable second transmission head 103, and a door cover 101 drivingly connected with the first transmission head 104.

[0031] The printer 100 also has a box accommodating chamber. One side of the box accommodating chamber has a box body insertion opening. The door cover 101 covers the box body insertion opening. The process cartridge 1 is inserted through the box body insertion opening and installed in the box accommodating chamber. The bottom wall 102 of the cartridge accommodating chamber is an inclined surface arranged from the driving end of the process cartridge 1 to the non-driv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap