Improved power cable device

A technology for power cables and fixing grooves, which is used in transportation and packaging, transportation of filamentous materials, and thin material handling, etc. problems, to achieve the effect of improving the efficiency of winding cables, simple structure and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

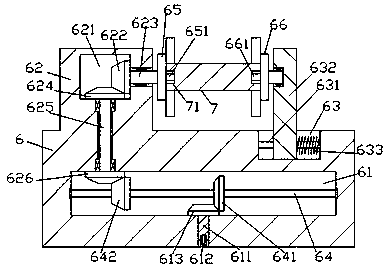

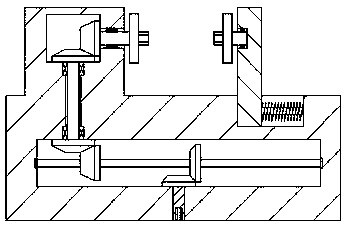

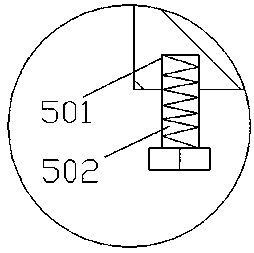

[0023] Such as Figure 1-Figure 4 As shown, an improved power cable device of the present invention includes a base 5 with a plurality of fixing grooves 52 in the top end surface and a winding element 6 arranged in the fixing grooves 52. The base 5. There are threaded holes 501 around the bottom, and threaded columns 502 are installed in the threaded holes 501. Each threaded column 502 can be adjusted up and down, so that the base 5 can be placed on uneven places. The interior of the base 5 below the fixing groove 52 is provided with a cavity 51 that is expanded left and right, and a main force arm 55 that is expanded left and right is provided in the cavity 51, and the inner bottom wall of each fixing groove 52 The first rotating arm 521 is connected with the rotation fit inside, the first transmission cavity 61 is arranged in the said winding element 6, the flange 62 is fixed on the left top end surface of the said winding element 6, and the said winding element 6 A guide g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com