Longitudinal-bar and I-steel-beam connection node and section-steel-beam-column connection structure

A technology of I-beam and connecting nodes, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of inconvenient on-site construction, affecting the structural strength and stability, increasing the processing difficulty of steel components, etc., to reduce the installation. Difficulty, saving labor costs, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

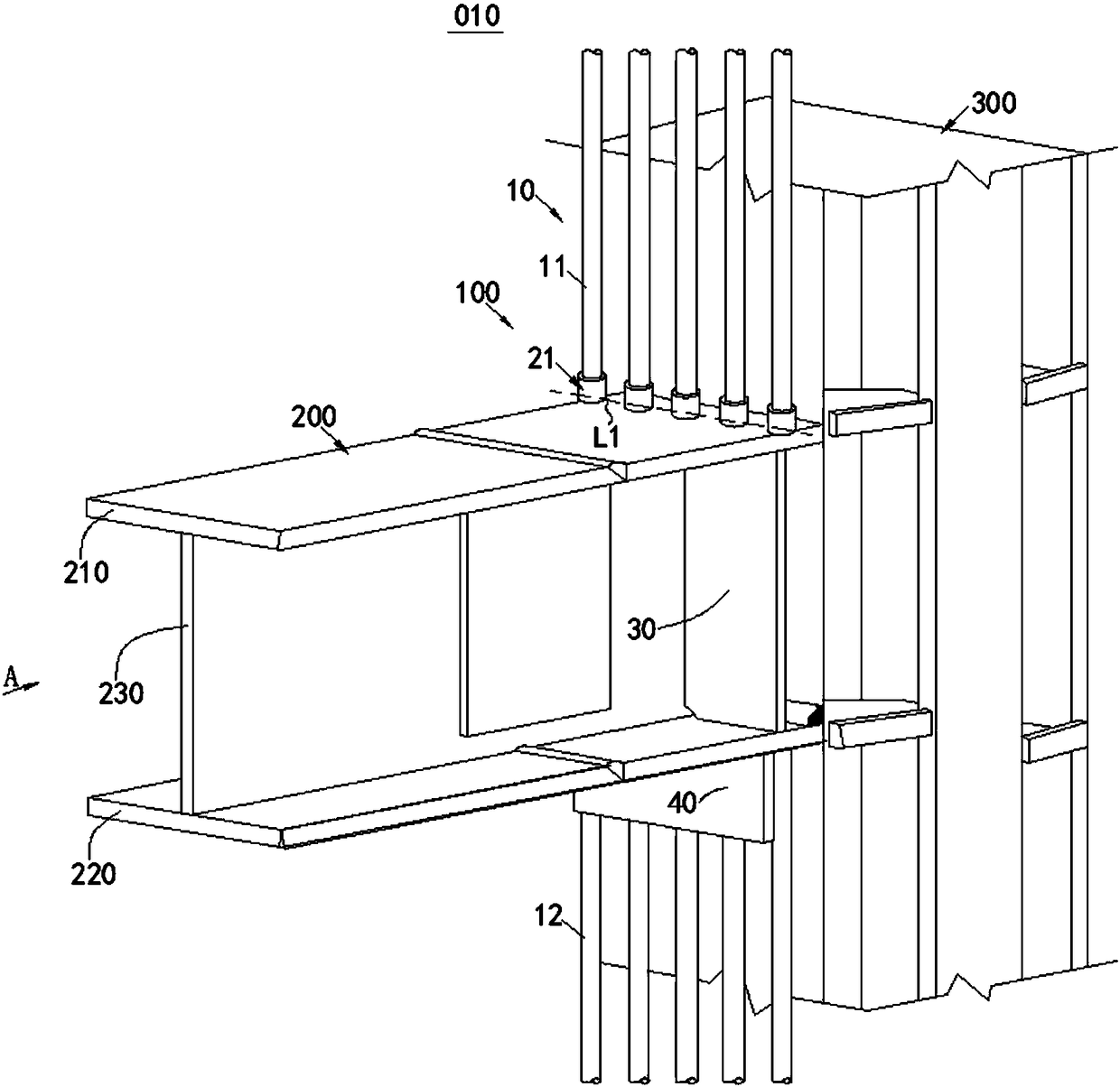

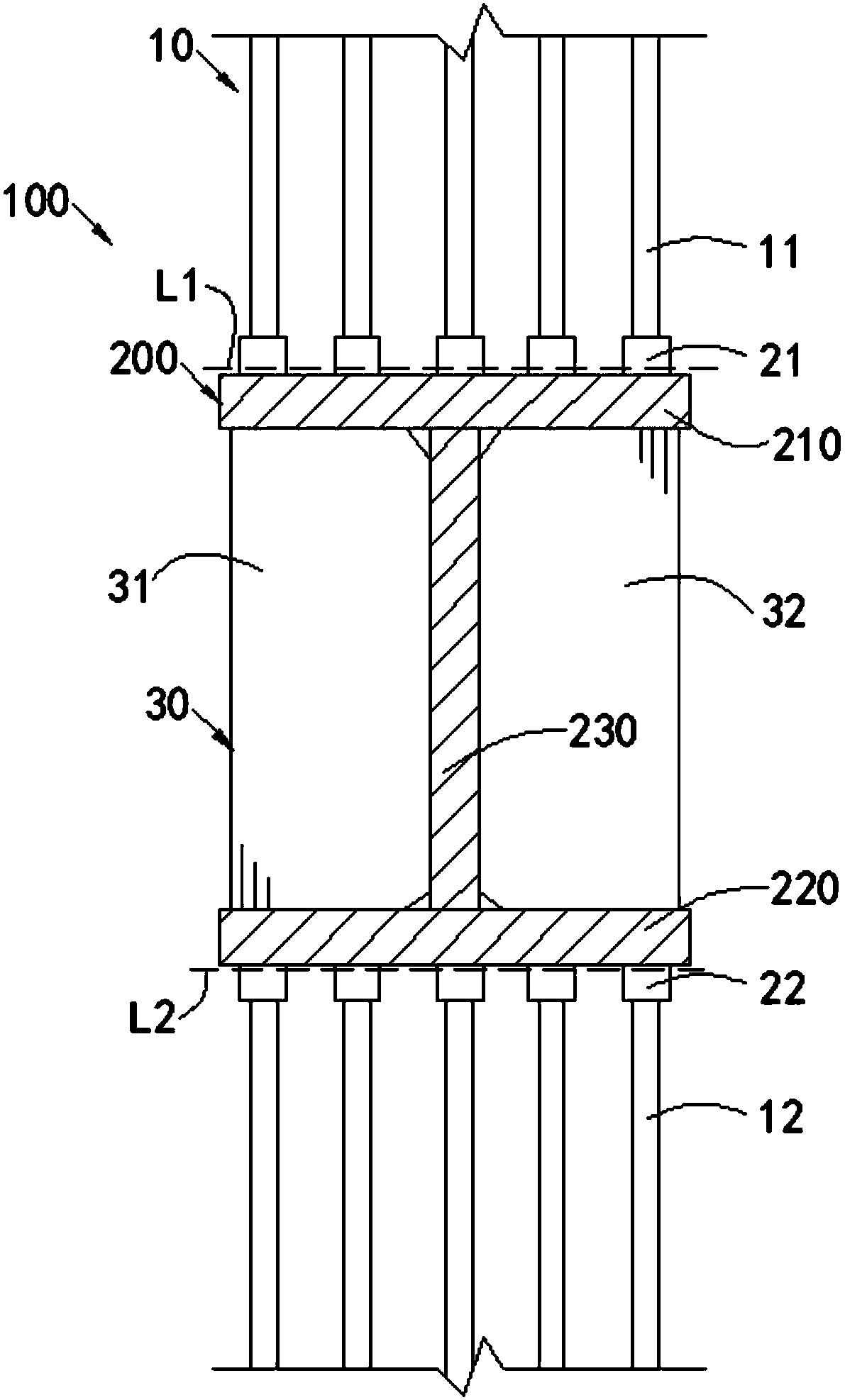

[0043] figure 1 It is a structural schematic diagram of the steel beam-column connection structure 010 in the embodiment of the present invention; figure 2 for figure 1 View along direction A (partial structure hidden). see figure 1 , figure 2, the steel beam-column connection structure 010 in this embodiment includes a steel column 300 , an I-beam 200 , and longitudinal bars 10 . The I-beam 200 is vertically connected to the side of the steel column 300 . The longitudinal reinforcement 10 is located outside the steel column 300 and vertically connected to the I-beam 200 . The connection between the longitudinal reinforcement 10 and the I-shaped steel beam 200 adopts the connection node 100 between the longitudinal reinforcement and the I-shaped steel beam.

[0044] The structure of the connection node 100 between the longitudinal reinforcement and the I-shaped steel beam in the present embodiment is as follows:

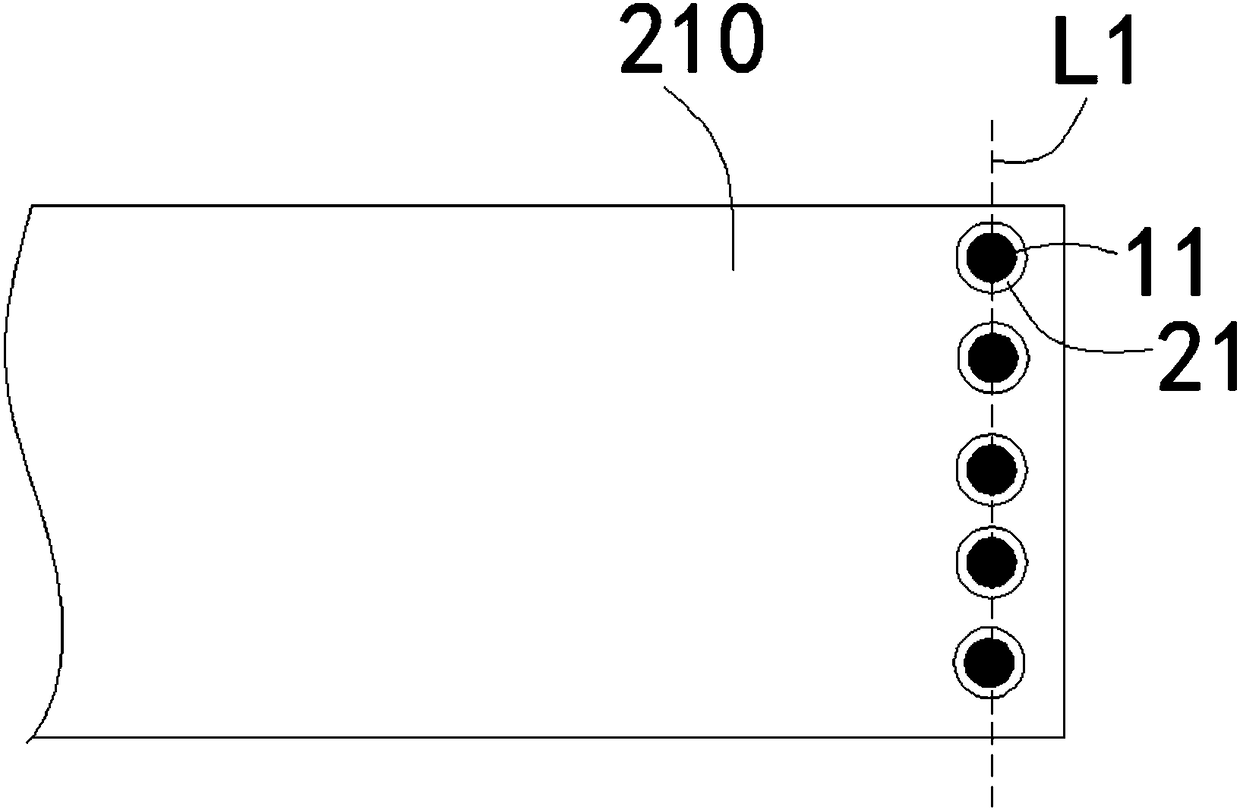

[0045] The upper surface of the upper wing plate 210 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com