Multifunctional tunnel construction operation car

A technology for tunnel construction and operating vehicles, which is applied to tunnels, tunnel linings, shaft linings, etc. It can solve the problems of difficulty in implementing support, few types of construction equipment, and many safety hazards, so as to reduce the process of manually completing the arch , shorten the arching time and improve the safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

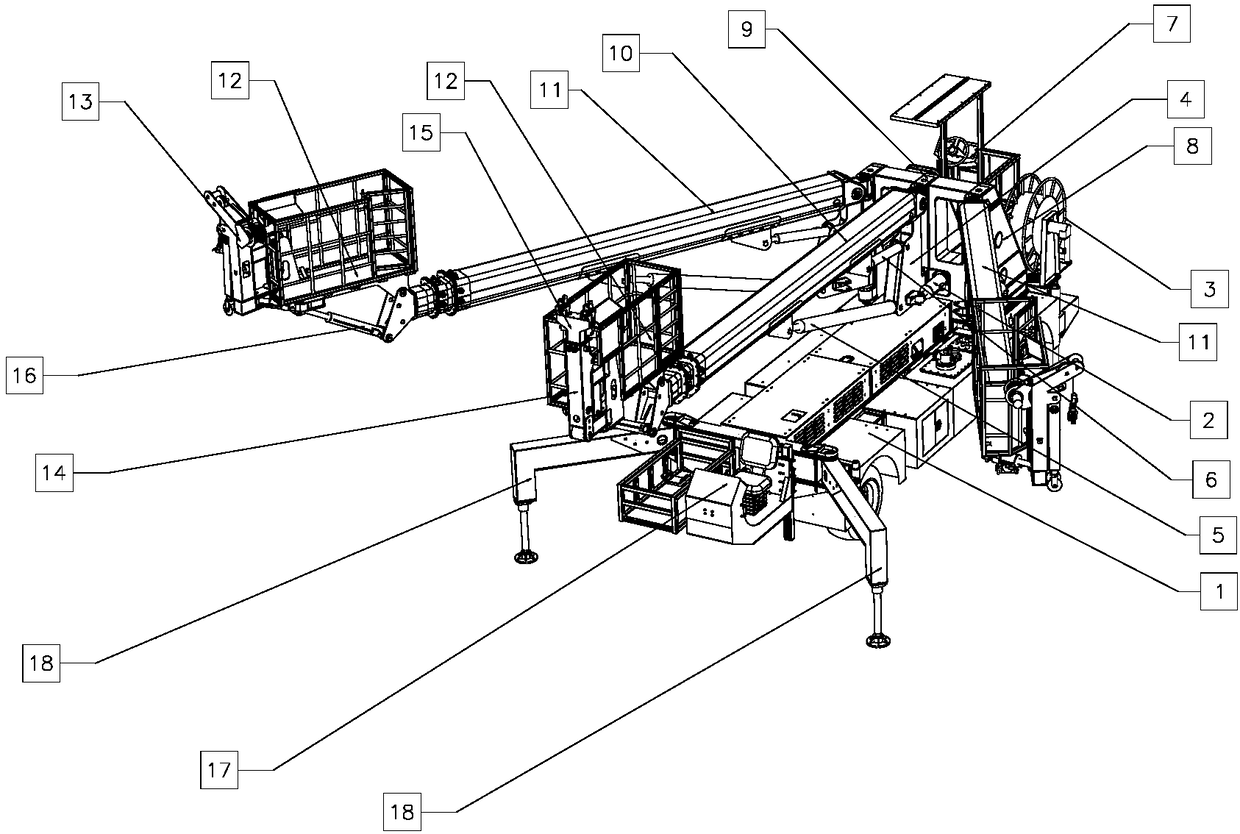

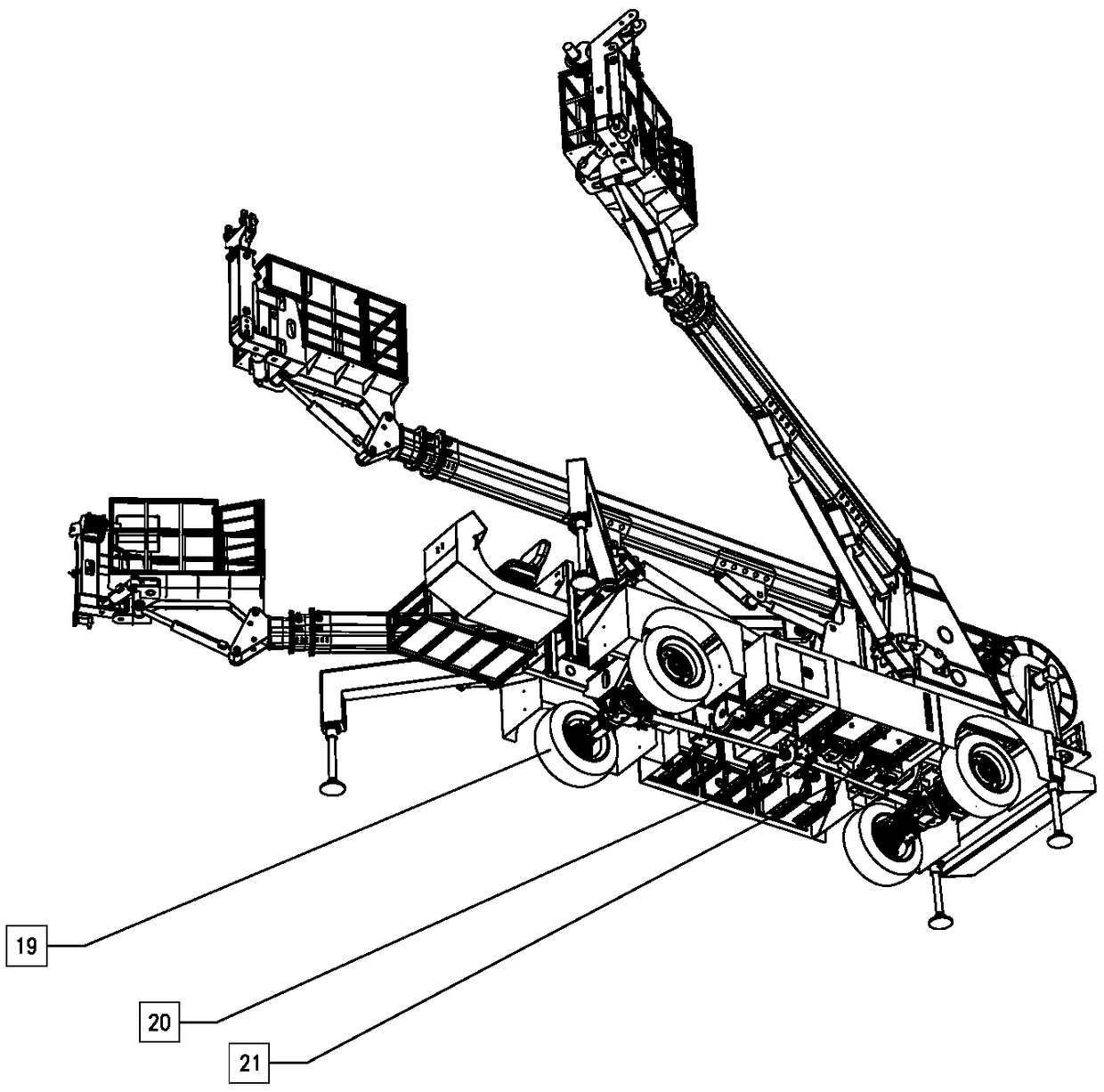

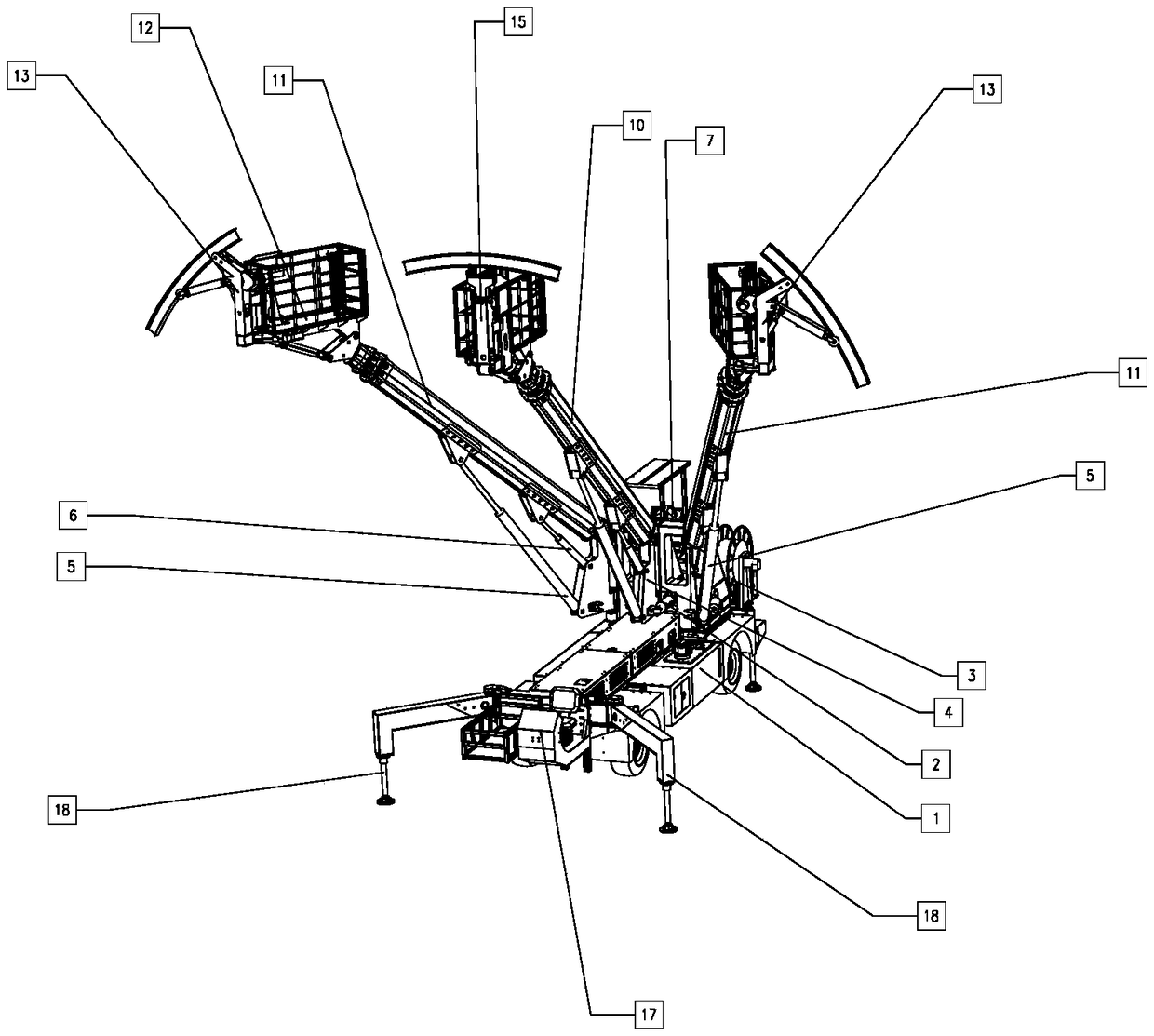

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] Such as Figure 1-6 As shown, the present embodiment provides a multi-functional tunnel construction operation vehicle, which includes a traveling device 1 on which three turntables 4 are arranged. An arm support device 9 is provided on the platform 4, and the arm support device 9 includes a main mechanical arm 10 and two auxiliary mechanical arms 11 arranged on both sides of the main mechanical arm, and each mechanical arm is respectively hinged with the corresponding turntable 4, Each mechanical arm is a telescopic mechanical arm, and each rotary table is driven by a rotary mechanism to realize the swing of each mechanical arm, and each mechanical arm is respectively driven by a corresponding pitch drive mechanism to realize the pitch motion of each mechanical arm, and the pitch drive mechanism Installed on the turntable 4, an operating platform 12 is respectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap