Production of in situ crosslinkable polyisobutylene-polyurethane nanofibers and coatings

A polyisobutylene and polyisobutylene diol technology, which can be used in coating, surgery, spinal nerve electrodes, etc., can solve the problems of time-consuming, difficult to manufacture polyisobutylene-polyurethane block copolymers, and solvent-based deposition processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Polymerization of PIB-PUR in 2,6-Lutidine

[0082] A mixture of 14.3 g of polyisobutylene diol (saturated, 88.8% polyisobutylene) and 6.82 g of polytetramethylene oxide diol was initially mixed with 50 g of toluene. The mixture was heated overnight at a temperature of 70° C. under a nitrogen purge to remove moisture and toluene. The mixture was charged into a 100 ml glass reactor along with 8.57 g methylene diphenyl diisocyanate and 65 g 2,6-lutidine. The mixture was stirred at 150 RPM and maintained at a temperature of 90°C. Agitation is provided by rotating Teflon paddles. After two hours, 0.02 g of tin(II) 2-ethylhexanoate and 3 ml of toluene were added to the reactor. After five minutes, 1.94 g of 1,4-butanediol and another 25 g of 2,6-lutidine were slowly added to the reactor to prevent the solution from containing 2,6-lutidine along with the reactants. Polymerizes in solution to form PIB-PUR and becomes too viscous. After one hour, the PIB-PUR solution is r...

Embodiment 2

[0084] Deposition of PIB-PUR in 2,6-lutidine by electrospinning

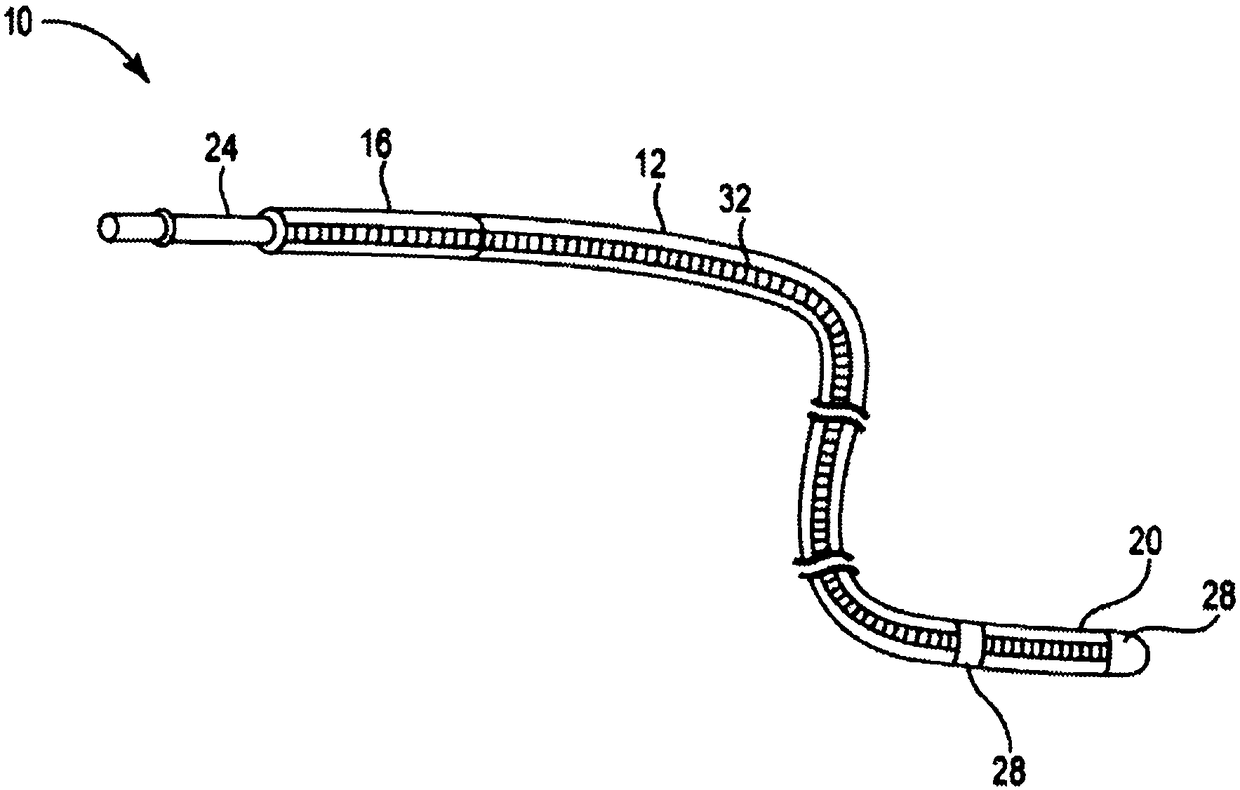

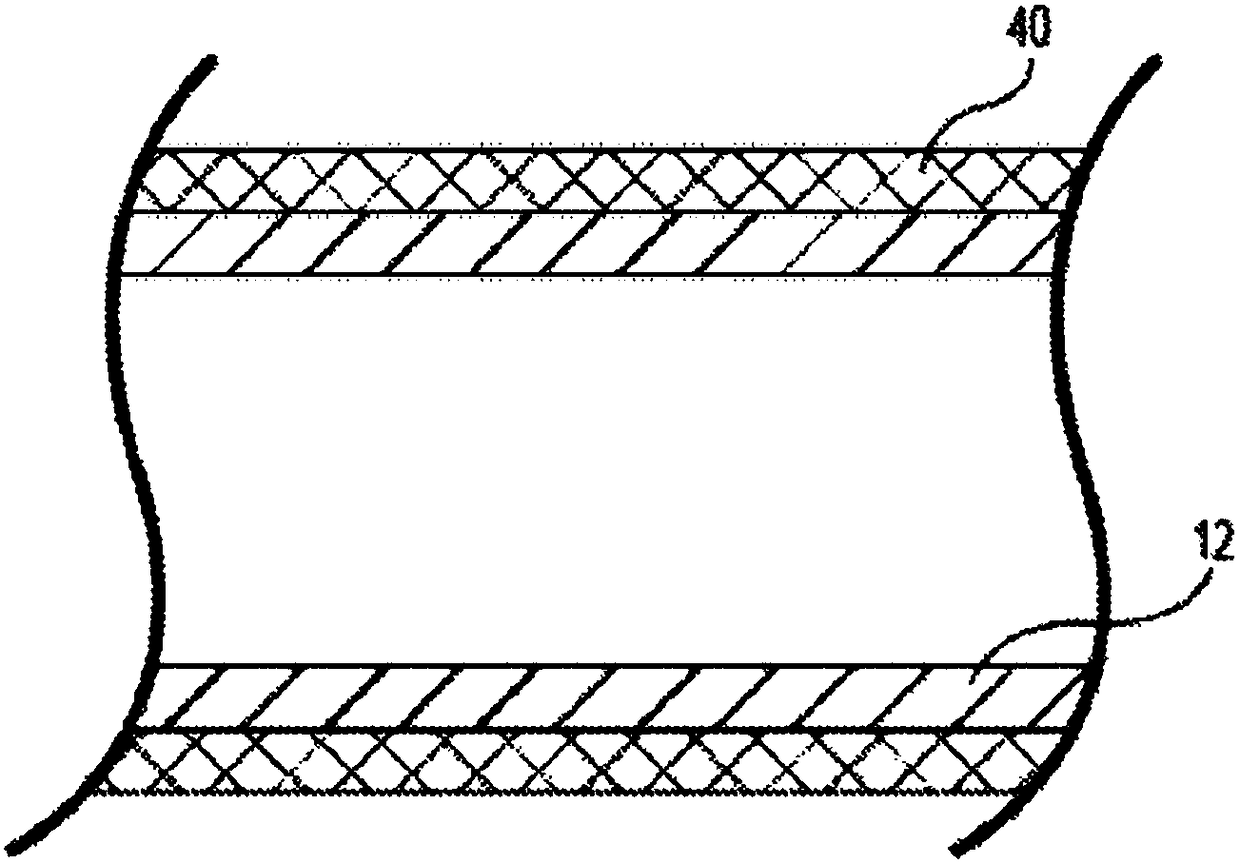

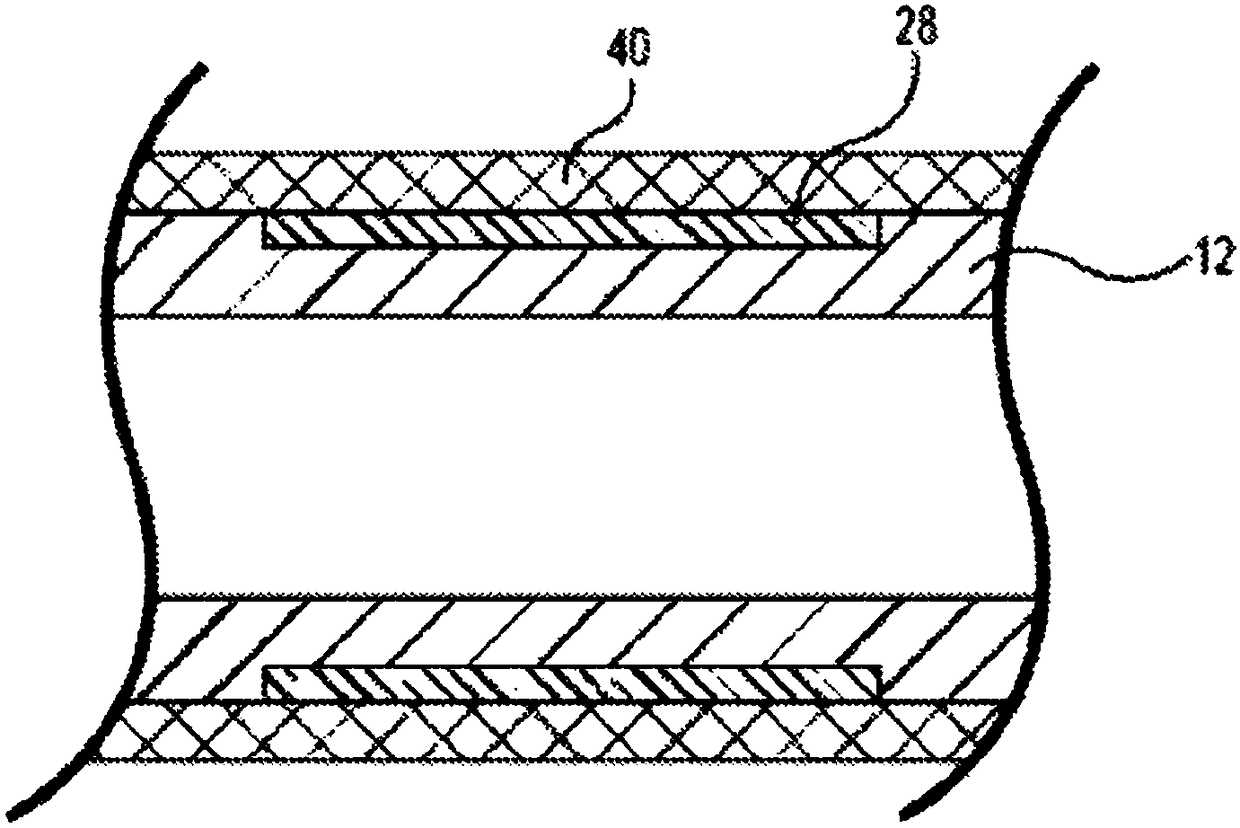

[0085] Lithium bromide salt (LiBr) was combined with a mixture of PIB-PUR solutions prepared as described above in Example 1 to form a solution containing 0.1% by weight LiBr. Fill the syringe with the PIB-PUR solution / salt mixture and connect to the nozzle of the electrospinning machine. The PIB-PUR solution / salt mixture was electrospun at a flow rate of 0.3 mL / h onto the electrode coil of a medical electrical lead at a distance of 10 cm from the nozzle tip to form a polymer network on the electrode coil. Environmental conditions included a relative humidity of 34% and a temperature of 23°C. Figure 4 A 1000X magnification image of the thin polymer network of the as-prepared PIB-PUR.

Embodiment 3

[0087] Deposition of PIB-PUR in 2,6-lutidine by spraying

[0088] A mixture of 69.795 g of the PIB-PUR solution prepared as described in Example 1 and another 75 ml of 2,6-lutidine was treated in a centrifuge at 5000 RPM for 20 minutes to dilute the PIB-PUR solution from a viscosity of 0.354 Pa ·s decreased to 0.048Pa·s. The PIB-PUR content was measured as 26.6% before dilution and 15.2% after dilution. Load the diluted PIB-PUR solution into Gravity air brush and spray onto braided inner coils for medical electrical leads. The coil was set on a mandrel rotating at 350 RPM at room temperature and 60.2% relative humidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com