Epoxy molding compound for high power soic semiconductor packaging applications

An epoxy molding and compound technology, which is used in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve problems such as being unsuitable for high-voltage applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

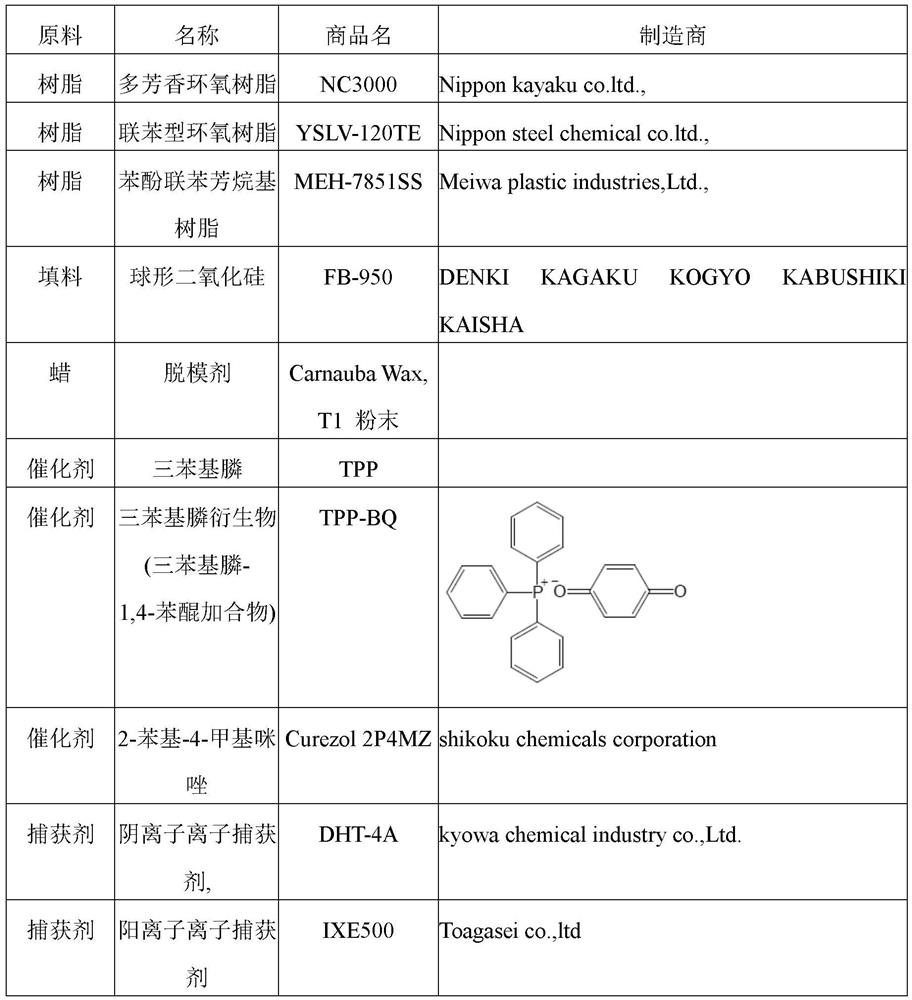

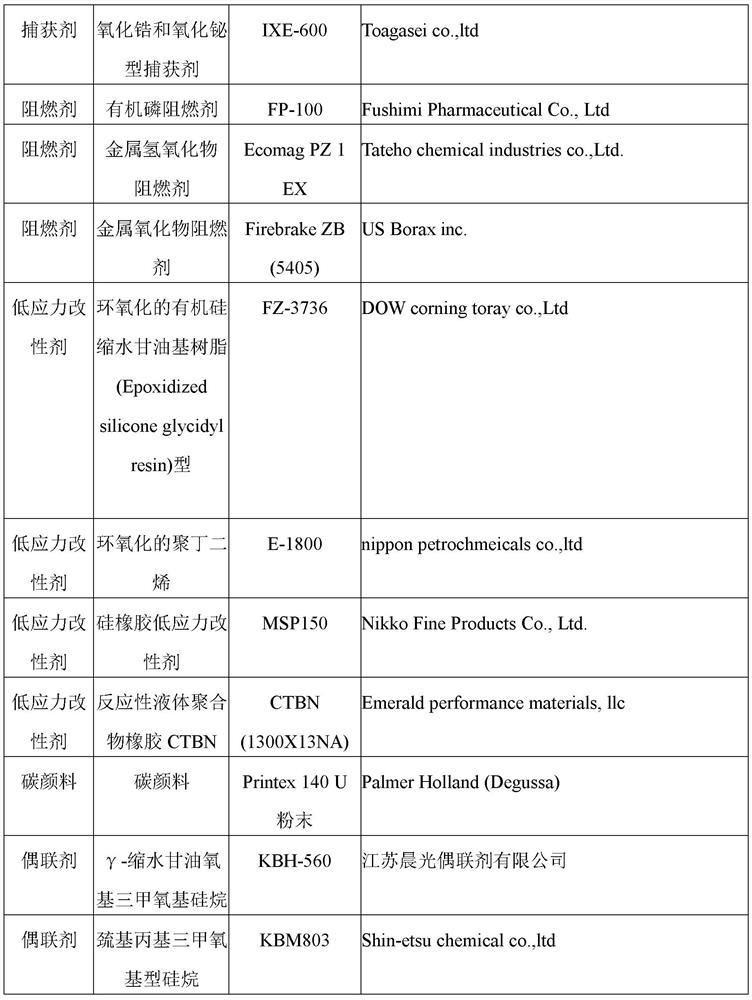

Method used

Image

Examples

preparation example Construction

[0091] The method for preparing the epoxy molding compound of the invention is not particularly limited. In a preferred embodiment, the epoxy molding compound is prepared by a process comprising the following steps:

[0092] (1) Accurately weigh each component and mix it in a high-speed mixer for 20-30 minutes;

[0093] (2) Add liquid additives to the mixer and continue mixing for 15-20 minutes,

[0094] (3) Pass the mixed material through a twin-screw extruder, and knead the extruded material at 90-110°C,

[0095] (4) Finally the material is cooled and ground.

[0096] The epoxy molding compounds of the present invention are useful for packaging IC devices.

[0097] Epoxy molding compounds for IC devices can be cured by conventional molding methods such as transfer molding, compression molding, etc.

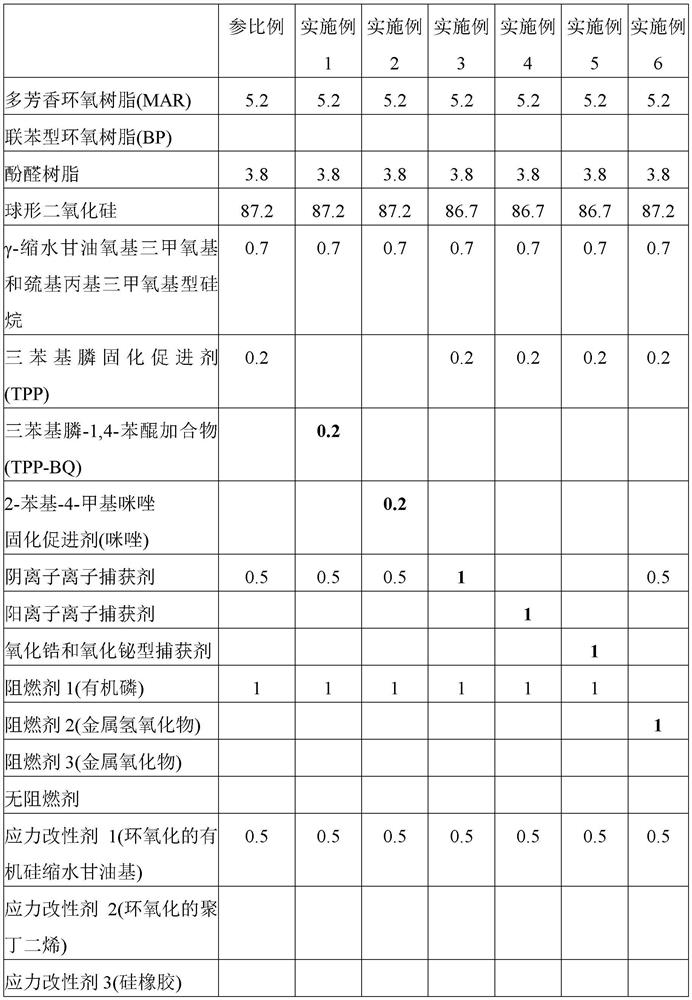

Embodiment 1

[0155] Polyaromatic epoxy resin (MAR), 5.2%

[0156] Phenol biphenyl aralkyl resin, 3.8%

[0157] Spherical silica, 87.2%

[0158] Gamma-glycidyloxytrimethoxy and mercaptopropyltrimethoxysilanes, 0.7%

[0159] Release agent, 0.6%

[0160] Epoxidized Silicone Glycidyl Resin Type Low Stress Modifier, 0.5%

[0161] Anion Ion Scavenger, 0.5%,

[0162] Organophosphorus flame retardant, 1%

[0163] Carbon pigment, 0.3%

[0164] Triphenylphosphine derivative, 0.2%

Embodiment 2

[0166] Polyaromatic epoxy resin (MAR), 5.2%

[0167] Phenol biphenyl aralkyl resin, 3.8%

[0168] Spherical silica, 87.2%

[0169] Gamma-glycidyloxytrimethoxy and mercaptopropyltrimethoxysilanes, 0.7%

[0170] Release agent, 0.6%

[0171] Epoxidized Silicone Glycidyl Resin Type Low Stress Modifier, 0.5%

[0172] Anion Ion Scavenger, 0.5%,

[0173] Organophosphorus flame retardant, 1%

[0174] Carbon pigment, 0.3%

[0175] 2-Phenyl-4-methylimidazole curing accelerator, 0.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com