Fixing frame for glass transferring

A fixed frame and glass turning technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of glass damage, small glass placement, and low practical performance, so as to improve safety and reliability and ensure stable placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

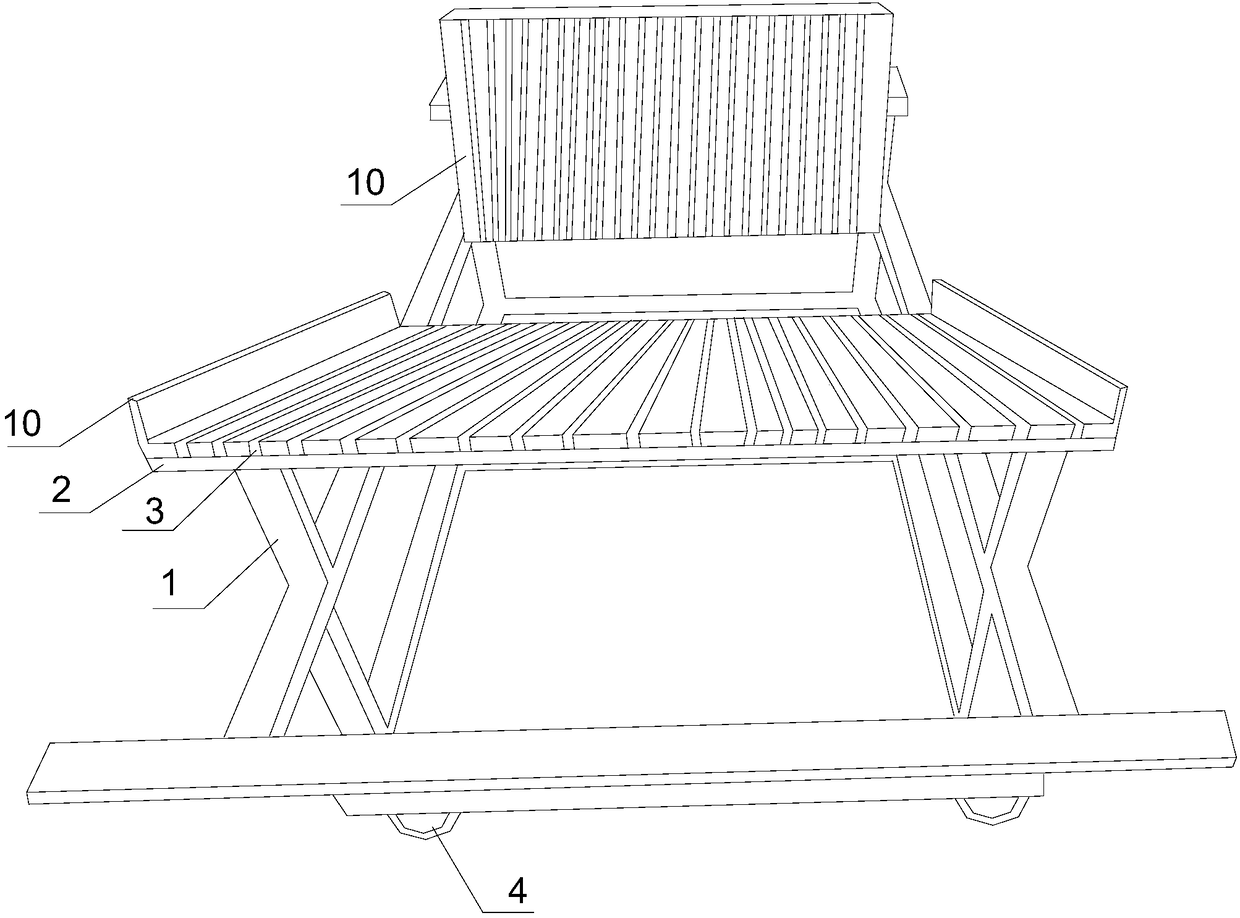

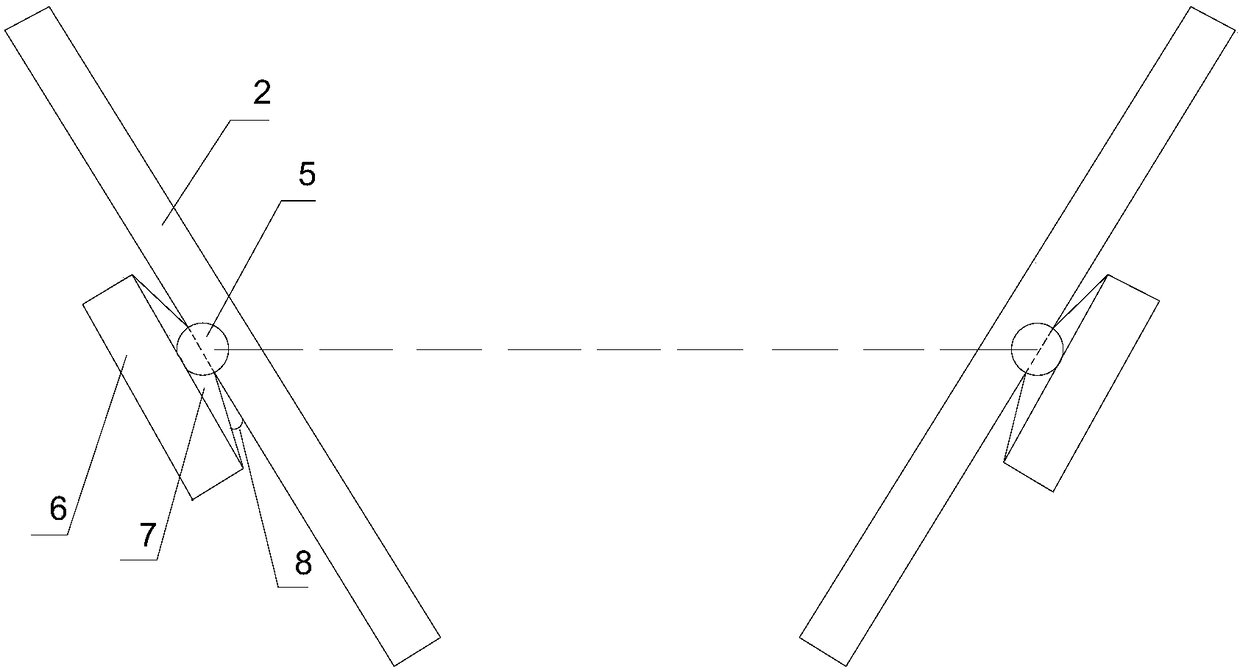

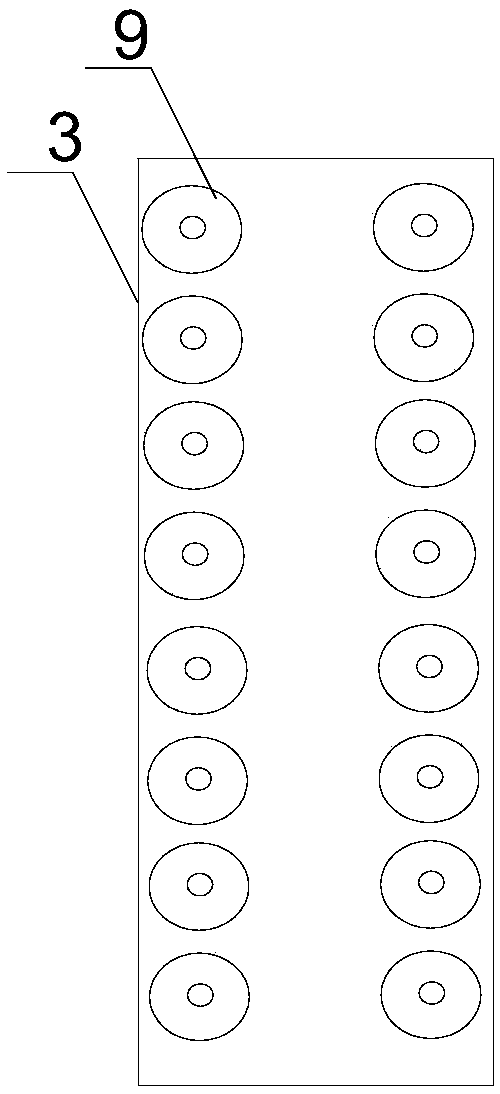

[0023] Such as figure 1 , figure 2 and image 3 As shown, a fixed frame for glass transfer in the present invention includes a bracket 1, a rotating shaft 5 and two baffles 2, and the two baffles 2 are relatively inclined on the bracket 1 through the rotating shaft 5. A plurality of grooves 3 are arranged on the upper surface, and the groove depth of the grooves 3 increases gradually along the inclination direction of the baffle plate 1. A plurality of pulleys 9 are installed on the inner walls of both sides of the groove 3, and a limit body is also included. The limiting body is arranged at the connection between the baffle plate 2 and the bracket 1; the limiting body includes a square block 6 and a protrusion 7, and the protrusion 7 is arranged on the square block 6, and the section of the protrusion 7 is an isosceles trapezoid, The square block 6 is bolted to the bracket 1, the baffle 2 is arranged on the top of the protrusion 7 through the rotating shaft 5, and the rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap