Hardening processor for plastic septic tank

A technology for septic tanks and processors, applied in sludge treatment, special treatment targets, water/sludge/sewage treatment, etc., can solve problems such as residue residue, difficult cleaning, and reduced work efficiency, so as to avoid time-consuming Many, to avoid low work efficiency and save energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

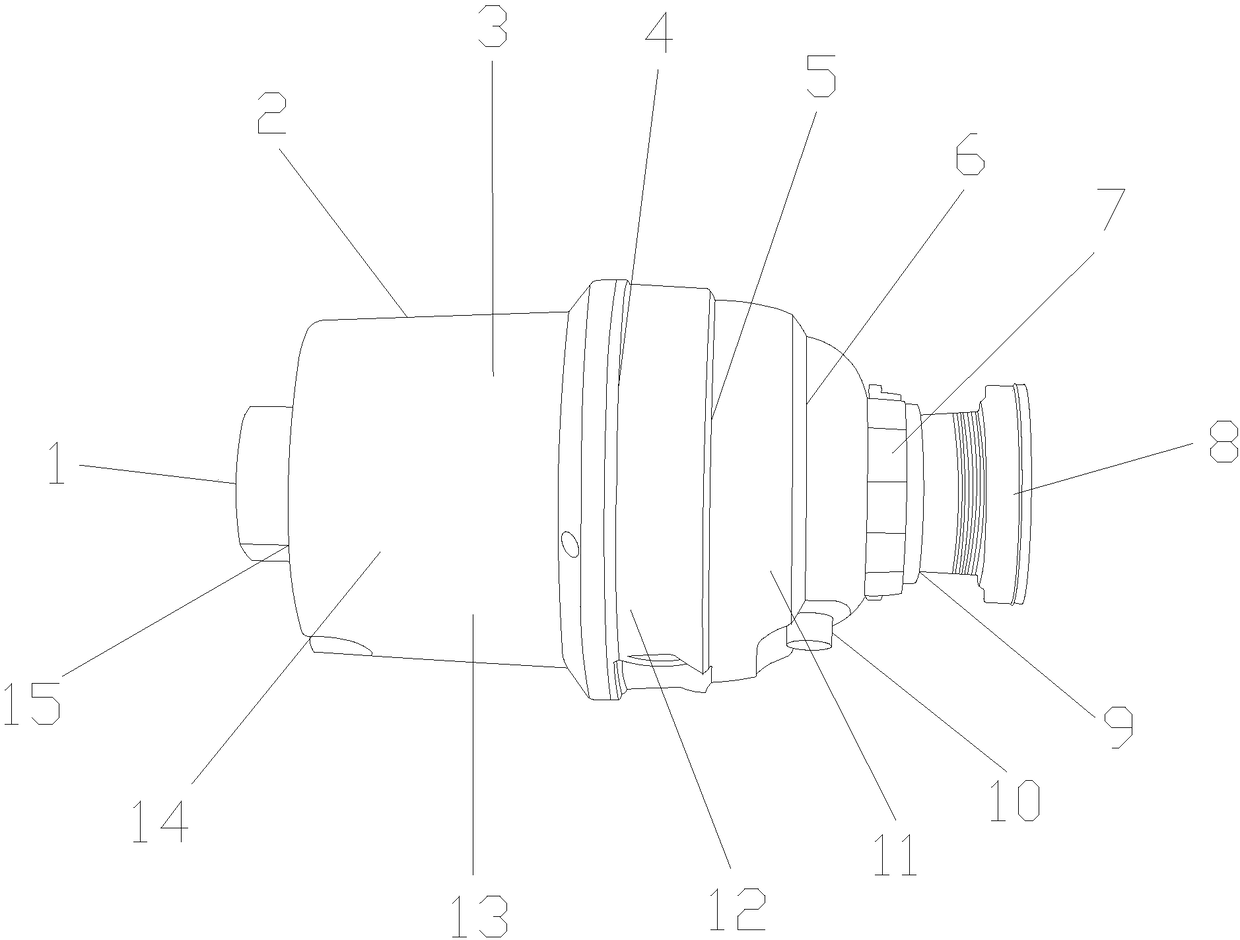

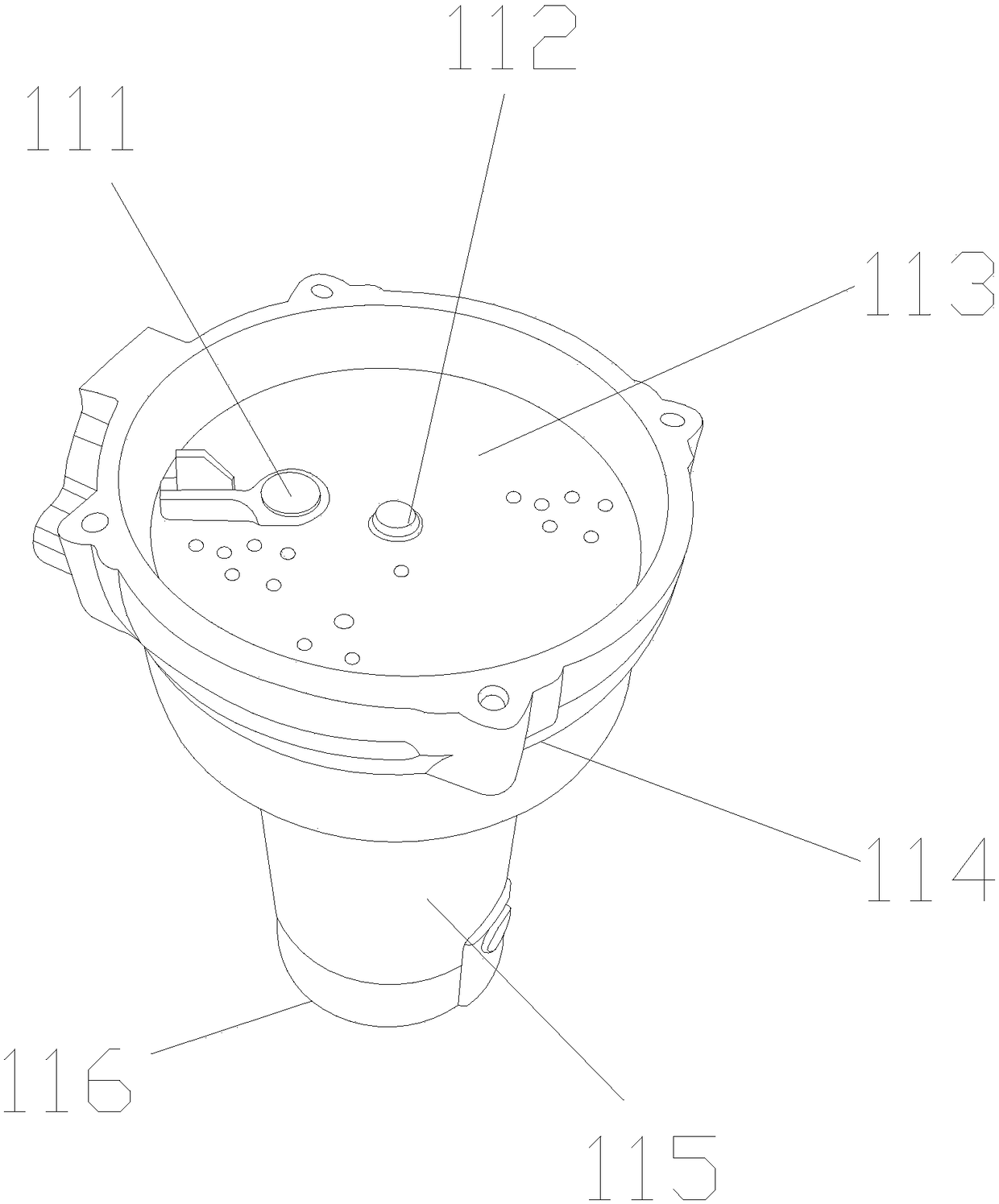

[0017] see Figure 1-Figure 2 , the present invention provides a technical solution: a plastic septic tank hardening processor, the structure of which includes an inlet 1, a main body 2, a valve seat 3, a drain valve core 4, a drain valve spring 5, a drain valve spring Seat 6, sealing ring 7, outlet 8, gland 9, discharge port 10, self-cleaning device 11, plunger 12, push rod 13, compression device 14, motor 15, the inlet 1 is connected with the fuselage body 2, The valve seat 3 is connected with the discharge valve core 4, the discharge valve spring 5 is connected with the discharge valve spring seat 6, the discharge port 10 is connected with the self-cleaning device 11, and the self-cleaning device 11 By the outlet 111, the pressure valve 112, t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap